Improved concrete mixer

A technology for concrete mixers and mixing boxes, applied in cement mixing devices, clay preparation devices, mixing operation control, etc., can solve the problems of unrecyclable cleaning water and waste of resources, and achieve reasonable structure, resource saving, and production cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

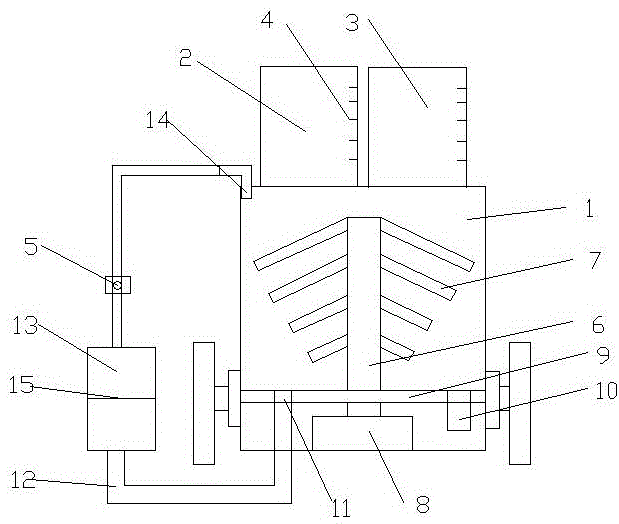

[0016] An improved concrete mixer of the present invention comprises a mixing box 1, the upper sides of the mixing box 1 are respectively provided with a feeding box 2 and a water inlet box 3, and the feeding box 2 and the water inlet box 3 are made of transparent materials , the surface of the feed box 2 and the water inlet box 3 is provided with a scale mark 4, the inside of the stirring box 1 is provided with an agitator, and the agitator includes an agitating shaft 6 arranged at the center of the agitating box 1 and an agitating shaft arranged on the agitating shaft 6 Stirring blade 7, stirring blade 7 decreases successively from top to bottom, the bottom of stirring shaft 6 is provided with driver 8, is provided with separating plate 9 between agitator 6 and driver 8, is provided with discharge port 10 and The water outlet 11 is connected to the water outlet pipe 12 , and the water outlet pipe 12 is connected to the purified water tank 13 arranged outside the mixing tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com