Clamping fixture for turning thin-walled pipe

A technology of turning and pipe fittings, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing processing accuracy, the influence of processing the outer wall of pipe fittings, and increasing the cost of use, so as to improve work efficiency and processing accuracy , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

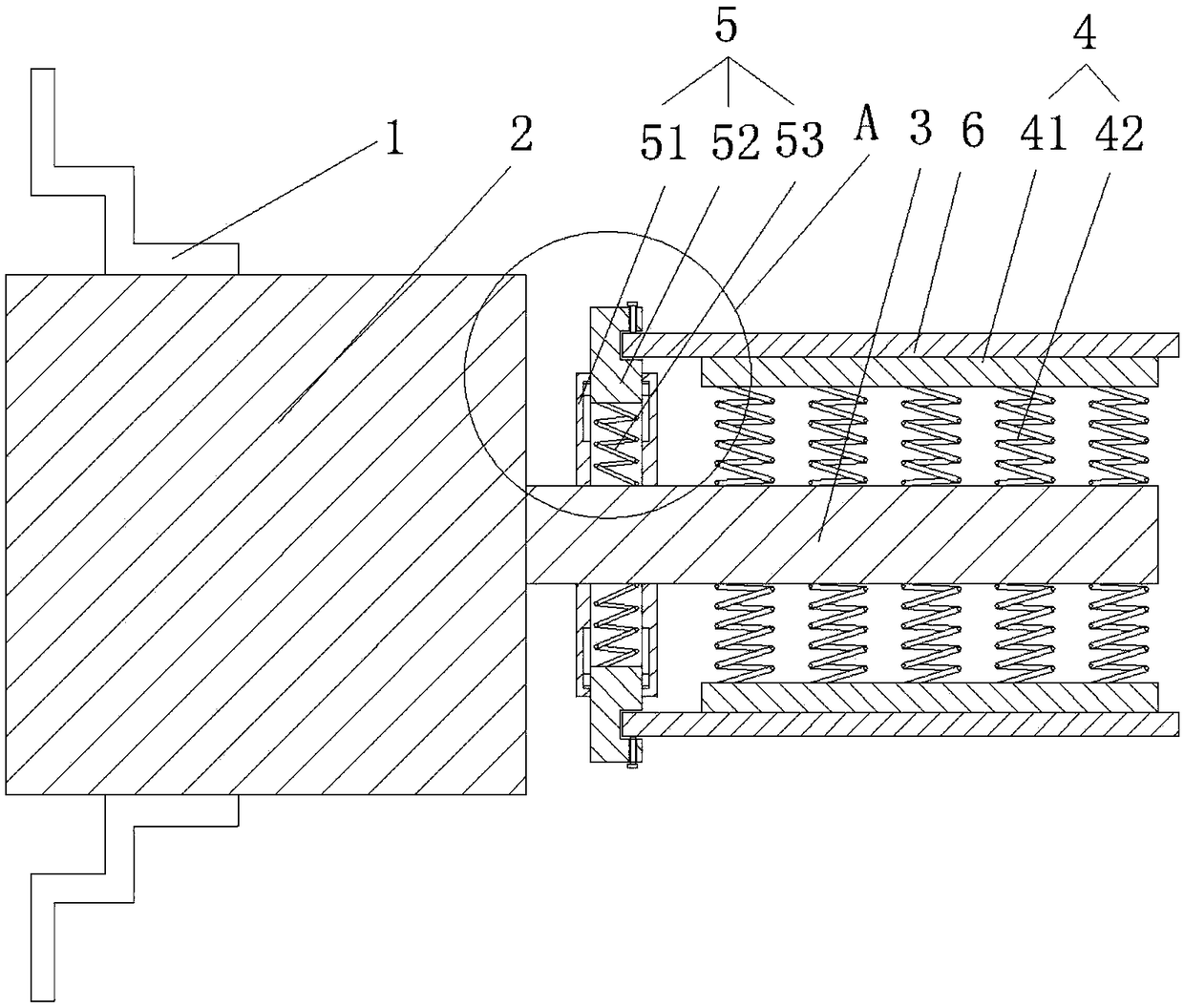

[0031] like image 3 As shown, the fixed shaft 3 and the fixed block 2 are integrally formed, and the fixed shaft 3 is provided with a clamping device 5 in the radial direction. The sliding groove 51, the sliding block 52 arranged in the sliding groove 51 and movable along the length direction of the sliding groove 51, and the sliding block 52 disposed in the sliding groove 51 along the length direction of the sliding groove 51 and used for connecting the sliding groove 51 and the sliding block 52 The tension spring 53 is provided on the sliding block 52 and the engaging groove 521 for engaging the pipe piece 6 is provided. The sliding slots 51 are integrally formed with the fixed shaft 3 , and there are four sliding slots 51 distributed in a circular array on the fixed shaft 3 , and are consistent with the distribution of the jaws of the four-jaw chuck 1 . The clamping device 5 can be clamped and adjusted according to the pipe fittings 6 of different diameters, and due to th...

Embodiment 2

[0034] like Figure 5 As shown, the fixed block 2 is movably connected with the fixed shaft 3, the fixed block 2 is provided with connecting holes 21 distributed axially along the fixed block 2, the connecting holes 21 are arranged on the axial center line of the fixed block 2, and the connecting holes 21 are provided with An internal thread, the outer surface of the fixed shaft 3 is provided with an external thread that cooperates with the internal thread. The fixed shaft 3 and the fixed block 2 are connected by threads, which can facilitate the installation and disassembly of the fixed shaft 3, and at the same time can ensure that the fixed shaft 3 and the fixed block 2 are located on the same central axis, and can also prevent the fixed shaft 3 from rotating and affect the machining accuracy. question.

[0035] As preferred, such as Image 6 As shown, the other end of the fixed block 2 corresponding to the connecting hole 21 is provided with a tapered hole 22 along the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com