Automatic adjustment vibration reducer

An automatic adjustment and shock absorber technology, which is applied in the direction of shock absorber, liquid shock absorber, shock absorber-spring combination, etc., can solve the problems of unable to adjust the main piston and limited vibration damping effect, and achieve good vibration damping effect , Improve the effect of resistance and quick damping function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

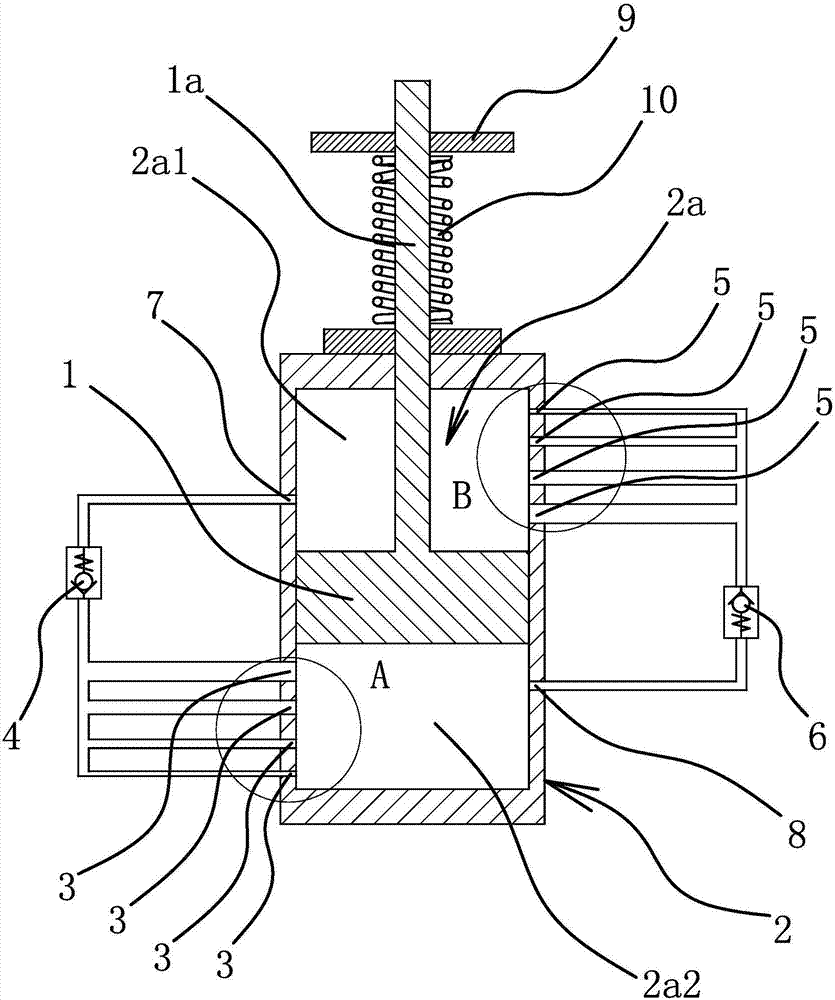

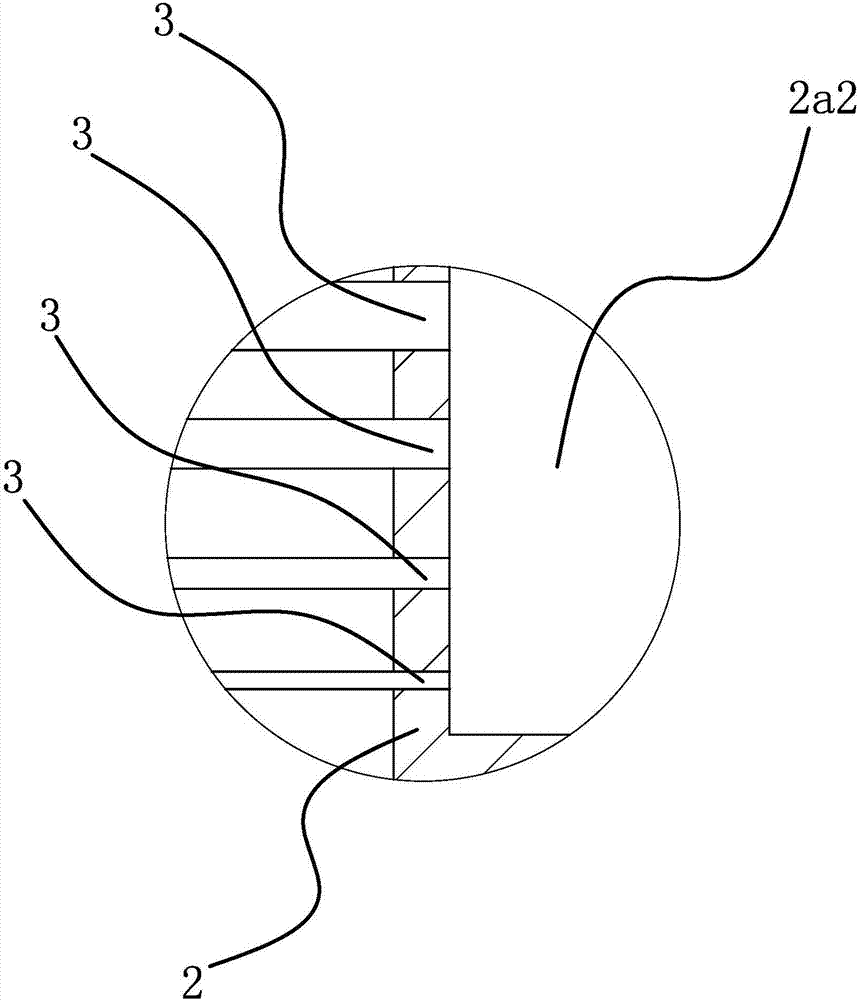

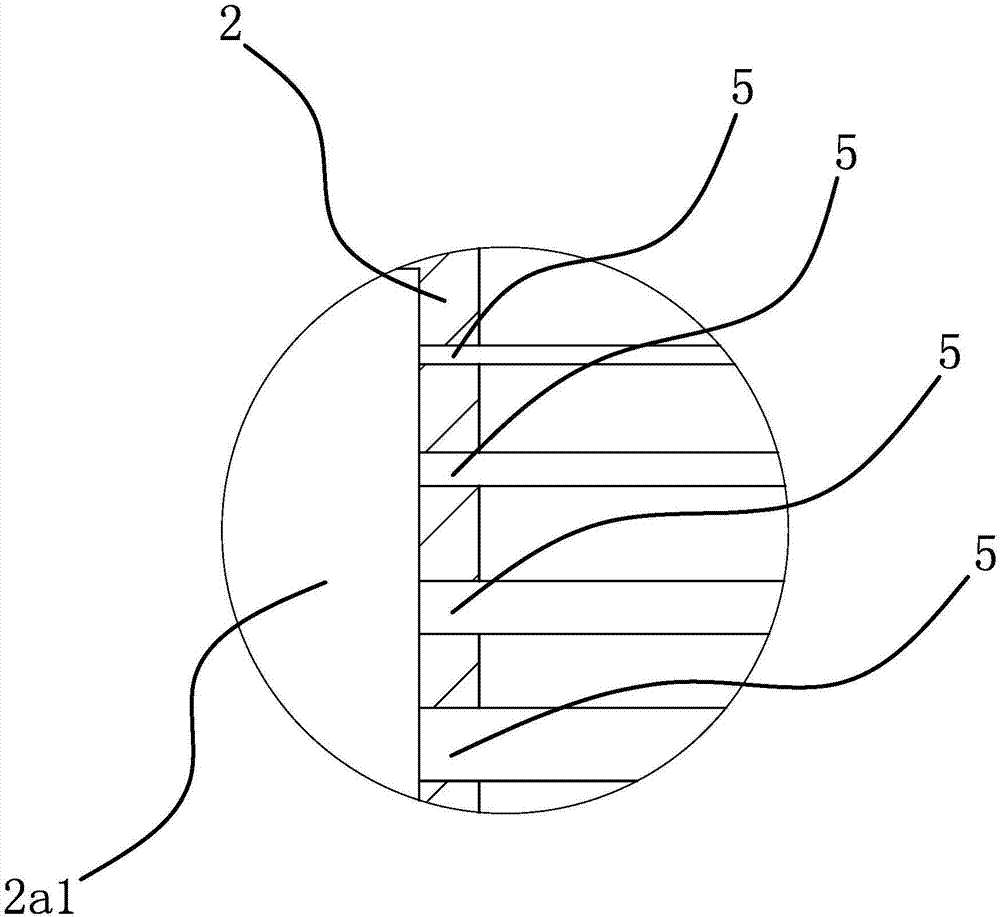

[0026] like figure 1As shown, the self-adjusting shock absorber includes a main piston 1, a piston rod 1a and a hydraulic cylinder 2, the hydraulic cylinder 2 has a working oil chamber 2a for containing oil, the main piston 1 is located in the working oil chamber 2a, and the main piston 1 Divide the working oil chamber 2a into an upper oil chamber 2a1 and a lower oil chamber 2a2, the lower end of the piston rod 1a is fixedly connected with the main piston 1, the upper end of the piston rod 1a is located outside the hydraulic cylinder 2, and on the side wall of the lower part of the hydraulic cylinder 2 There are several lower damping oil holes 3 connected with the lower oil chamber 2a2. The lower damping oil holes 3 are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com