Improved structure of heater of czochralski crystal growing furnace

A heater and single crystal furnace technology, which is applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of complicated operation and increased equipment investment, so as to reduce equipment investment, simplify operation procedures, and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

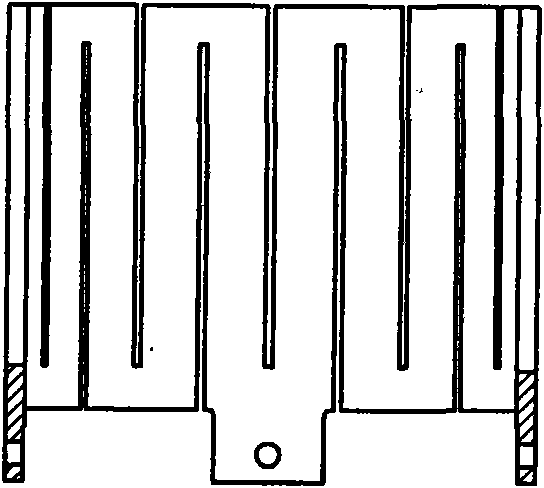

[0018] The improved structure of the graphite heater of the Czochralski single crystal furnace in specific embodiment 1 is as Figure 4 Shown:

[0019] A thinning heating section is arranged on a common annular graphite heater, and the radial cross-sectional area of the thinning heating section is 2 / 3~3 / 4 of the radial cross-sectional area of the rest of the heater; A section refers to a portion from the bottom of the heater to 1 / 5 to 1 / 4 of the total height. The thinned heating section has the same radial thickness as the rest of the heater, and the slot width of the thinned heating section is larger than the slot width of the rest of the heater.

specific Embodiment 2

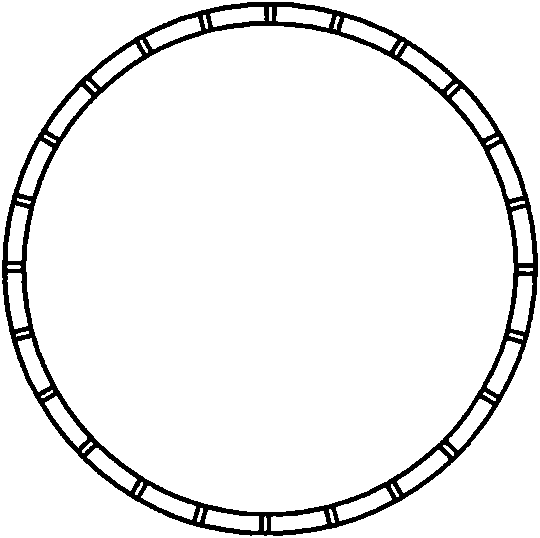

[0020] The improved structure of the graphite heater of the Czochralski single crystal furnace in specific embodiment 2 is as Figure 5 , 6 Shown:

[0021] A thinning heating section is arranged on a common annular graphite heater, and the radial cross-sectional area of the thinning heating section is 2 / 3~3 / 4 of the radial cross-sectional area of the rest of the heater; A section refers to a portion from the bottom of the heater to 1 / 5 to 1 / 4 of the total height. The thinned heating section has the same groove width as the rest of the heater, and the radial thickness of the thinned heating section is smaller than the radial thickness of the rest of the heater.

[0022] As long as the radial cross-sectional area of the thinning heating section is kept consistent, the effects of using these two methods are the same.

[0023] In the same way, the content of specific embodiment 3 can also be obtained:

[0024] A thinning heating section is arranged on a common annular gr...

specific Embodiment 4

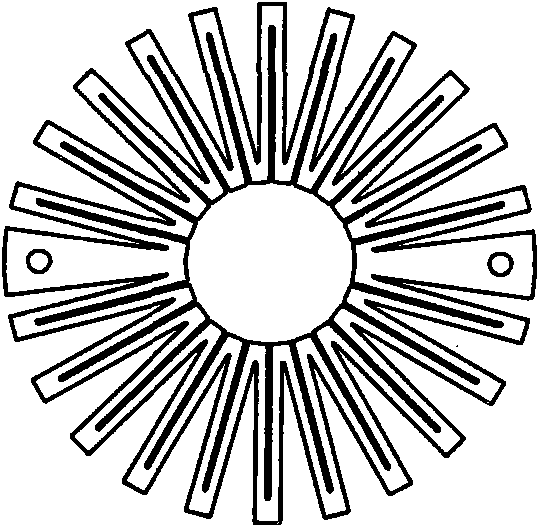

[0025] A 22-inch heater is used, the maximum power is 165KW, the total resistance of the heating sheet is 24 milliohms, 120KW power is applied when chemicalizing materials, and 80kW power is applied when the diameter is equal. The total height of the heater is 500mm. figure 1 The height of the lower part of the ordinary standard heater shown is 125mm heating sheet, the power is 30KW when the material is turned on, and the power is 20KW when the diameter is equal. Through design and processing, after reducing the cross-sectional area of the 125mm heating sheet at the lower part of the heater by 1 / 3, the power of the lower 125mm heating sheet of the single crystal furnace is 40kw when the material is chemicalized, and the power is 26.7kw when the diameter is equal, which is equivalent to adding a small bottom heater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com