Laminated core and method for manufacturing the same

一种叠层铁芯、制造方法的技术,应用在制造定子/转子本体、电气元件、磁路静止零部件等方向,能够解决电机性能降低等问题,达到面积增加、接合强度增大、防止剥离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

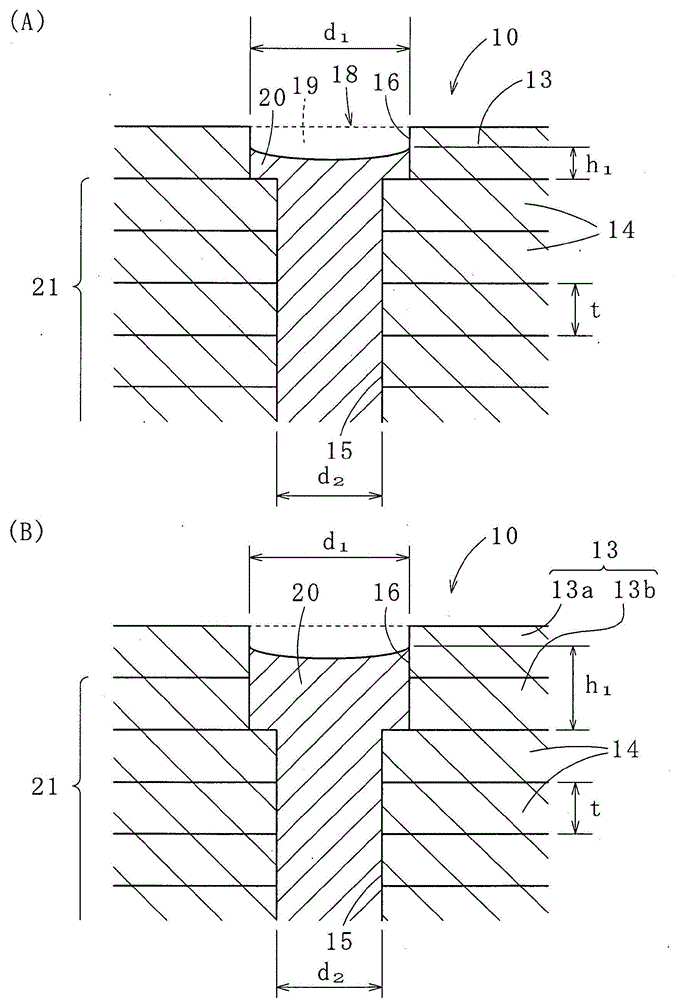

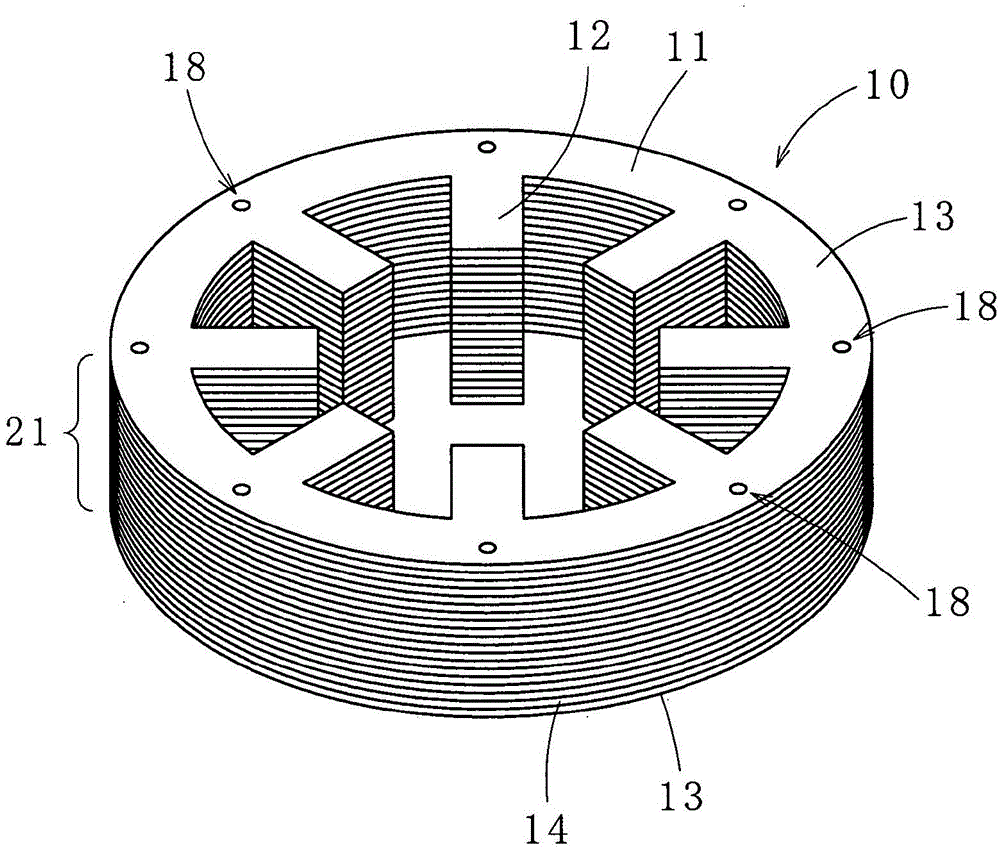

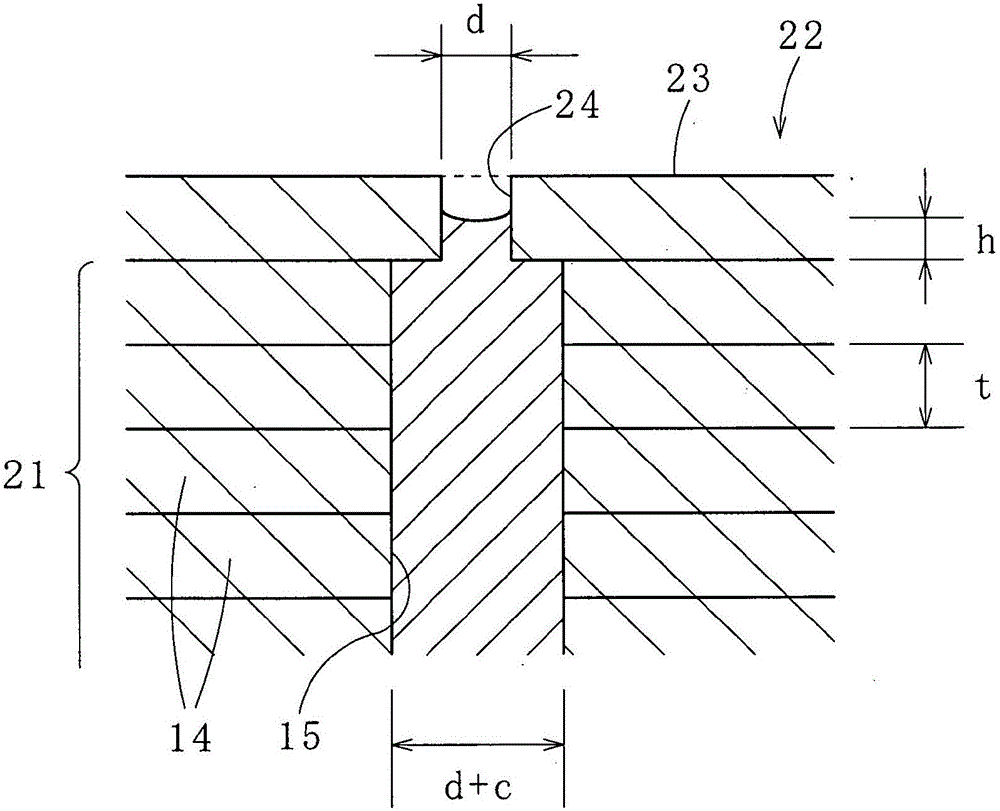

[0048] Next, specific embodiments of the present invention will be described with reference to the drawings. In the following embodiments, the core pieces on one side (specifically, the upper end) of the laminated iron core will be described, but the core pieces on the other side (specifically, the lower end) may have the same structure.

[0049] In addition, in the following embodiments, the stator laminated core will be mainly described, but it is also applicable to the rotor laminated core.

[0050] In addition, in the present invention including the following embodiments, the core sheet at the end in the axial direction is referred to as a core sheet (A), and the other core sheets are referred to as a core sheet (U), and are only referred to as "core sheets". It refers to the case of including the chip (A) and the chip (B) or generally referred to as the chip. In addition, in the present invention, the laminated core includes a case where the core pieces are only laminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com