Chip bonding device, chip bonding method and chip bonding quality evaluation equipment

A technology of chip bonding and bonding parts, which is applied in the field of chip bonding quality evaluation equipment, can solve the problems of lengthening the manufacturing process and hindering cost reduction, and achieve the effects of reducing gaps, ensuring bonding strength, and ensuring mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

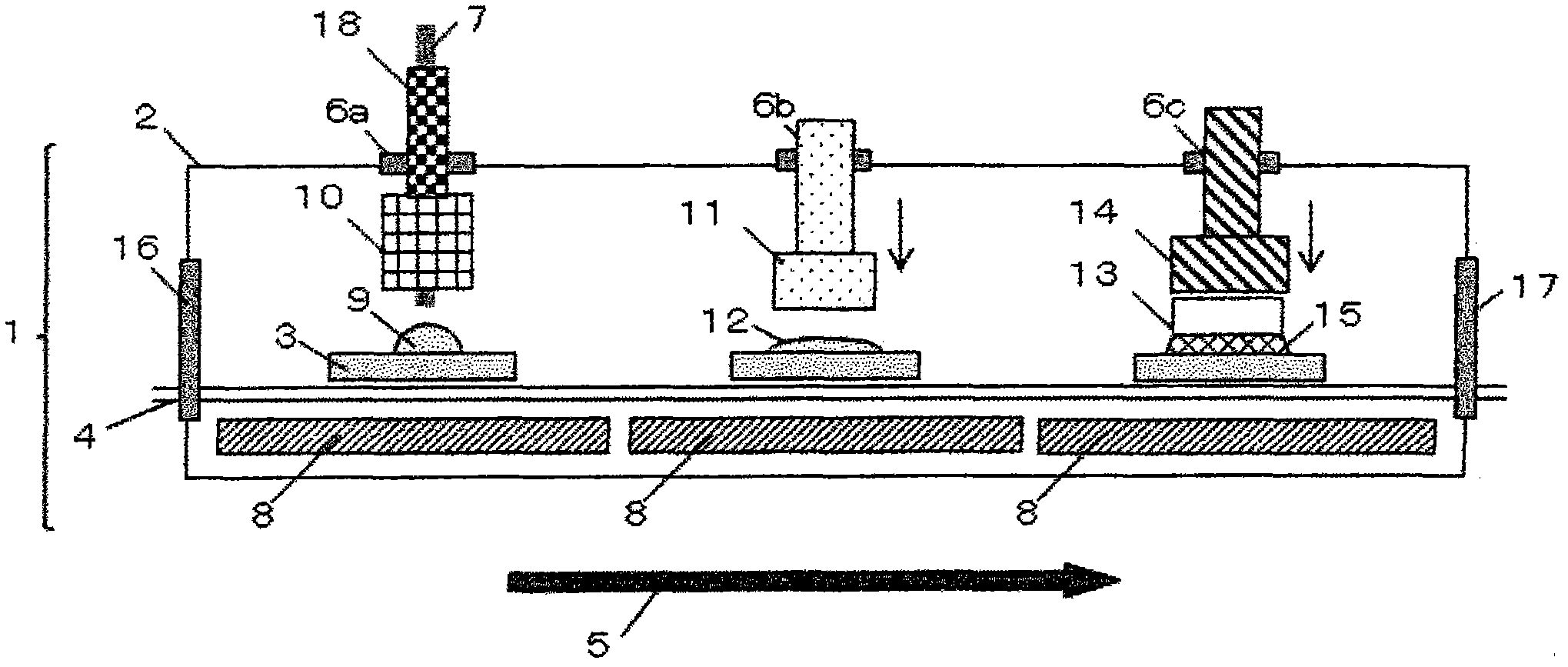

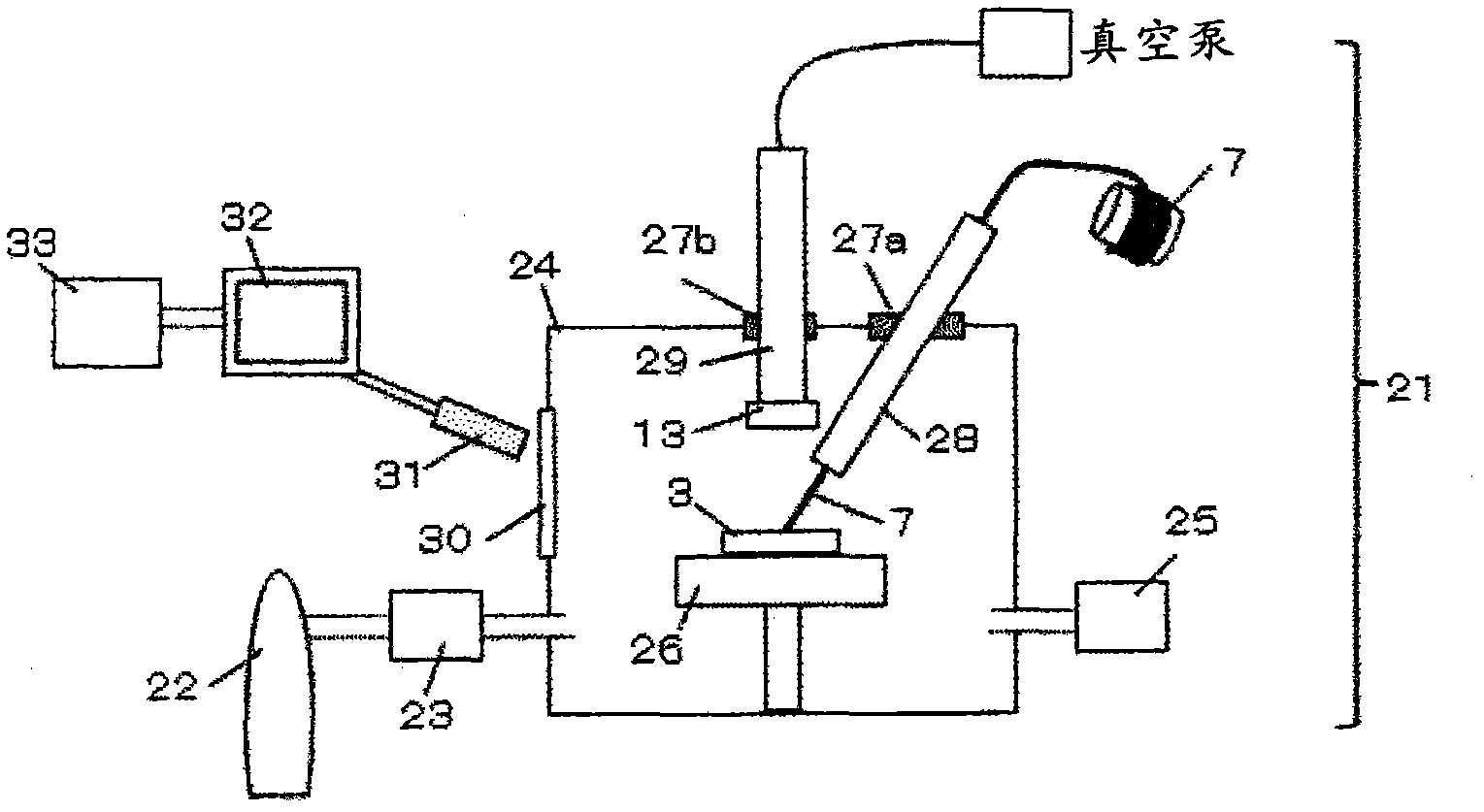

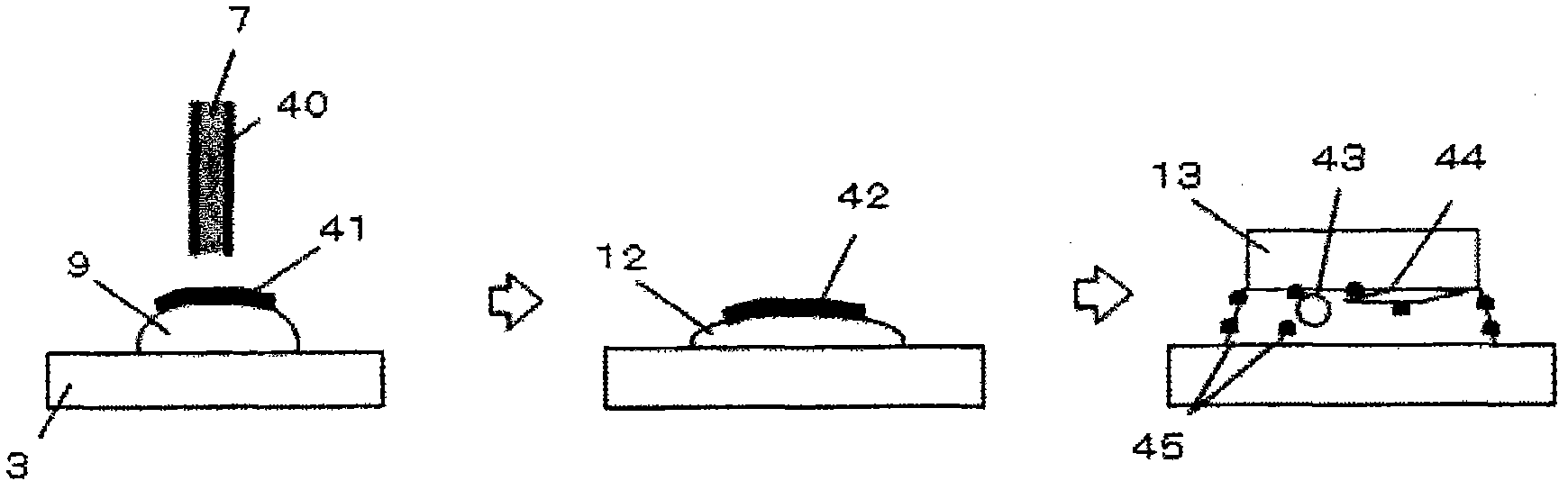

[0040] figure 1 It is an enlarged view of the main part of the die bonder with the solder surface cleaning unit of the present invention. This die bonder 1 is a device that is covered by a case 2 in order to block the outside air, has a guide rail 4 that intermittently moves a plurality of lead frames or substrates 3 as parts to be bonded, and runs along the lead frames or substrates 3. There are three opening windows 6a, 6b, 6c at predetermined positions on the casing (chamber) 2 in the moving direction 5. If it is described in terms of the chip bonding process, the first step is a solder supply part, which supplies long solder wires 7 to the lead frame or the substrate 3 through the opening window 6a. If this process is described in detail, the solder wire 7 sent from the solder supply nozzle 18, after passing through the surface cleaning unit 10, contacts the lead frame or the substrate 3 heated by the heater 8, and the front end of the solder wire 7 melts to wet the lead ...

Embodiment 2

[0059] As Embodiment 2 of this invention, the case where the atmospheric-pressure plasma processing method is used for the solder surface cleaning means is demonstrated. Other than that, it is the same as in Example 1. As the gas for the atmospheric pressure plasma processing, the mixed gas of nitrogen and hydrogen used as the atmospheric gas at the time of die bonding can be used as usual, and a new gas for processing is not required. However, a mixed gas of helium and hydrogen, a mixed gas of argon and hydrogen, or the like may be used in addition. In addition, since the treatment is carried out under atmospheric pressure, there is no need for opening and closing doors at the upper and lower ends of the solder surface cleaning unit 10, and it is possible to reduce the time for vacuum replacement, etc., and continuous treatment is possible, so the productivity is high. The way.

[0060] The plasma jet is arranged so as to collide with the side of the solder line 7 , but if ...

Embodiment 3

[0063] In Embodiment 3 of the present invention, a case where a method of reducing in an electrolytic solution is adopted as the solder surface cleaning means will be described. Other than that, it is the same as in Example 1. In this method, the solder wire 7 is passed through the electrolytic solution, and an electric current is passed through the part immersed in the solution, thereby causing reduction of the oxide film. Thereby, the amount of Sn oxide film on the solder wire can be reduced, and the voids in the die-bonding portion can be reduced, preventing wetting failure, and achieving high quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com