Side channel blower, in particular a secondary air blower for an internal combustion machine

A technology of secondary air and blower, which is applied to the components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., to achieve the effect of minimizing noise and noise emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

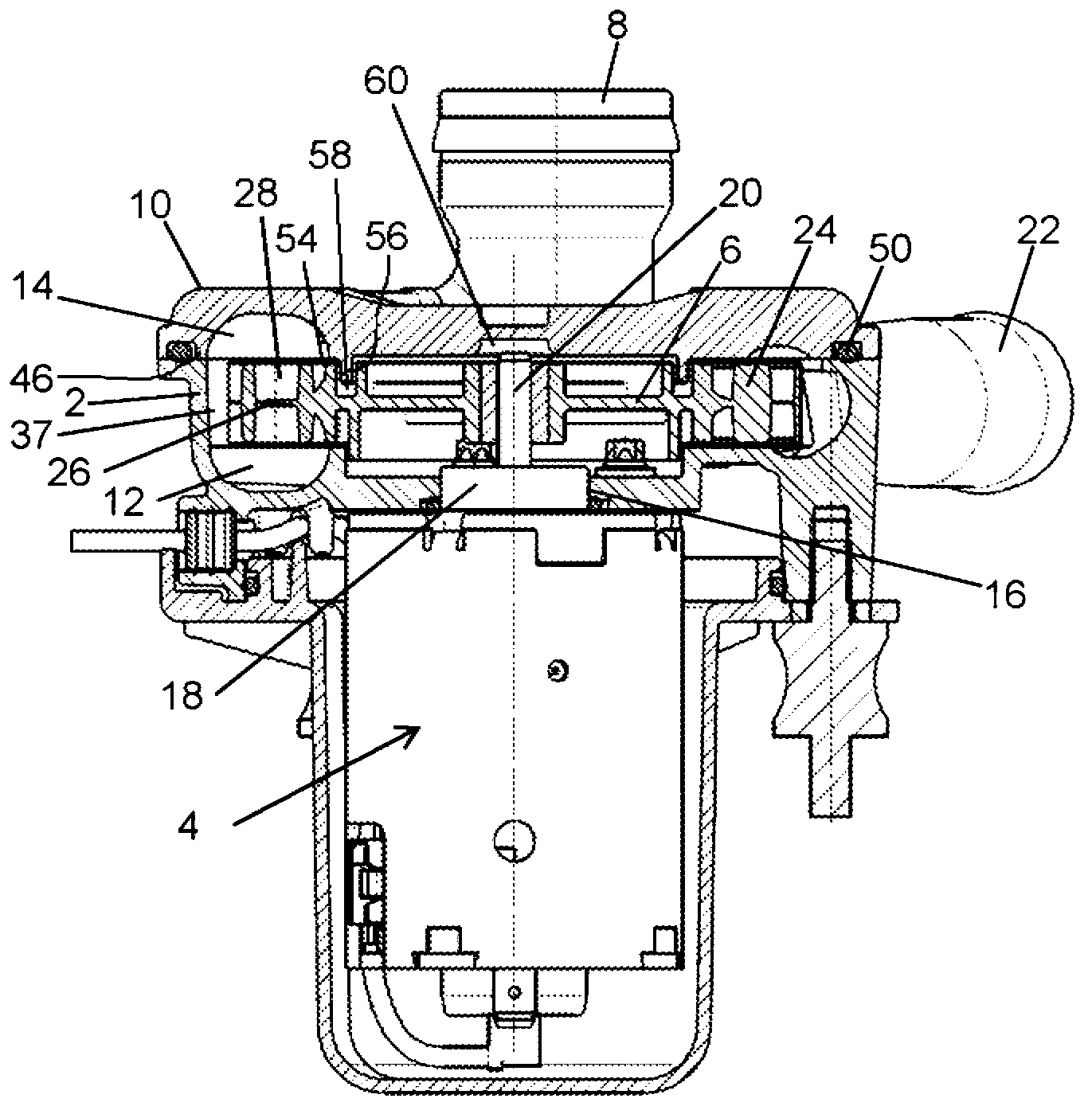

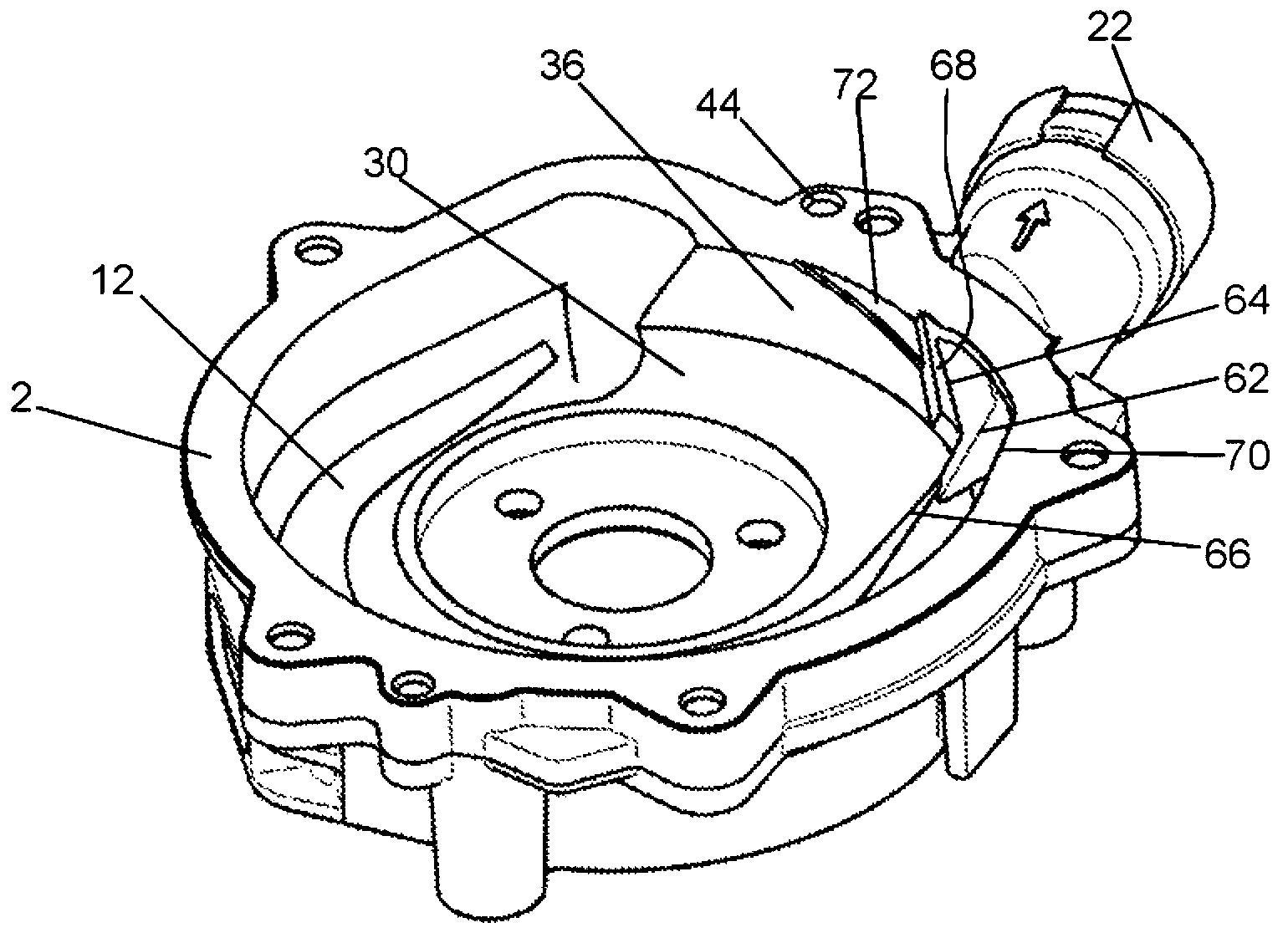

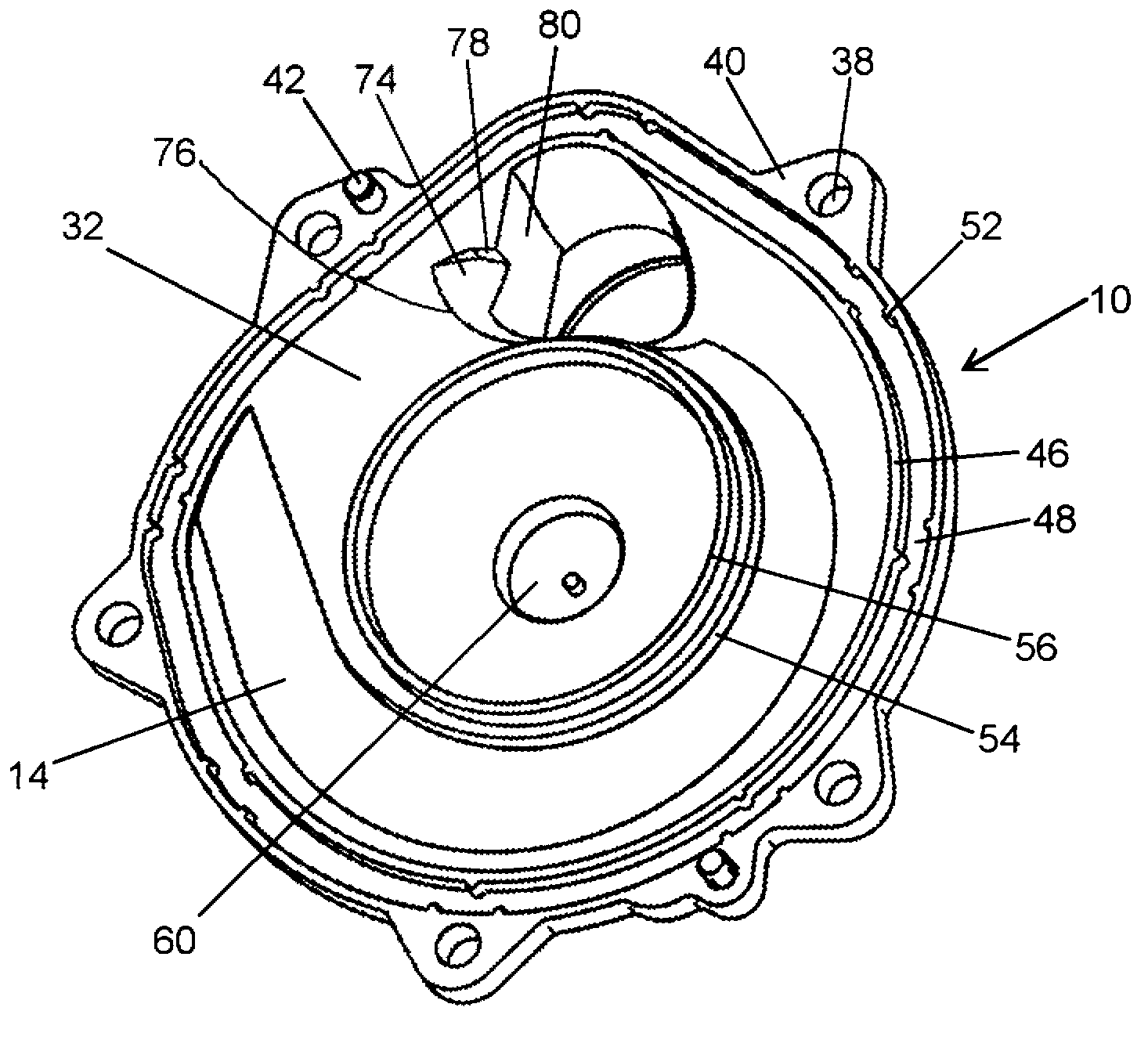

[0024] exist figure 1 The side-channel blower shown in FIG. 2 consists of a housing 2 and an impeller 6 , which is rotatably mounted in the housing 2 and driven by a drive unit 4 , for example for conveying air. Air enters the interior of the side channel blower through an axial inlet 8 formed in the housing cover 10 .

[0025] The air then flows out from the inlet 8 into two substantially annularly extending conveyor channels 12 , 14 , the first conveyor channel 12 of which is formed in the housing 2 . The bearing 18 of the drive shaft 20 of the drive unit 4 is also arranged in the central opening 16 of the drive unit 4 , on which the impeller 6 is fastened, and the second conveying channel 14 is formed in the housing cover 10 . The air exits through a tangential outlet 22 arranged in the housing 2 .

[0026] The impeller 6 is arranged between the housing cover 10 and the housing 2 and has curved conveyor blades 24 on its circumference, wherein the general direction of exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com