Friction part for a frictionally acting device, and frictionally acting device having a friction part of said type

A technology of friction parts, friction action, applied in the field of friction parts for friction action devices and friction action devices with said type of friction parts, capable of solving friction lining damage, clutch difficulty, groove pattern reduction to such An obvious degree or other problems are eliminated, achieving the effect of simplification of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

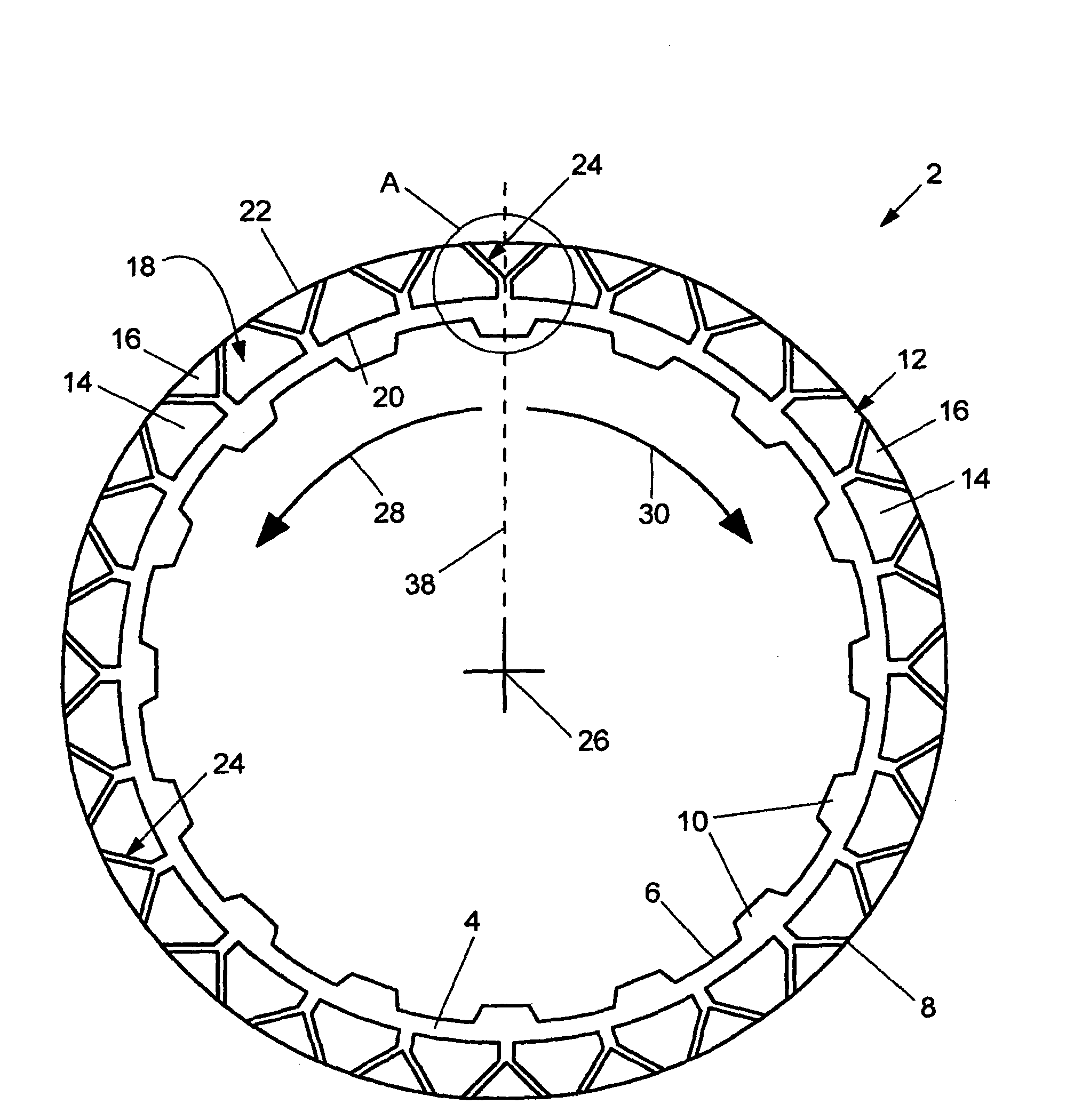

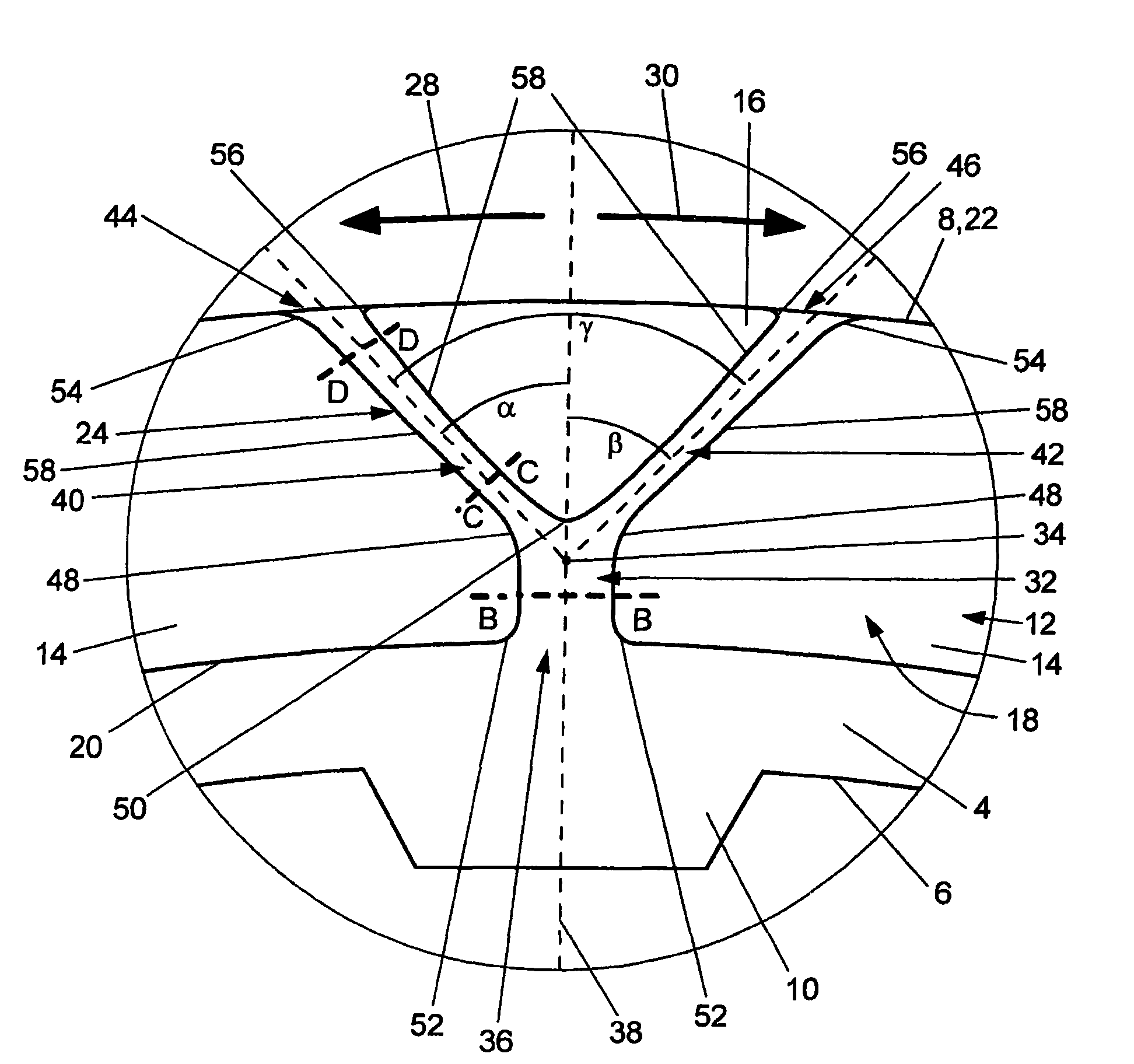

[0050] figure 1 A first embodiment of a friction component 2 for a friction device according to the invention is shown. The shown friction component 2 is embodied in the case of the variant as a plate for a multi-plate clutch and initially has a lining carrier 4 . The lining carrier 4 is embodied as an annular steel disk and comprises an inner edge 6 and an outer edge 8 . The inner rim 6 is provided with radially inwardly protruding teeth 10 formed in one piece with the disk of the ring and spaced from each other in the circumferential direction. Via these teeth 10 it is possible to connect the disc (which is therefore a so-called inner plate) rotationally and fixedly to a shaft of the clutch. However, it should be pointed out that the friction part 2 according to the invention could also be an outer plate, wherein the teeth would then be arranged on the outer edge 8 .

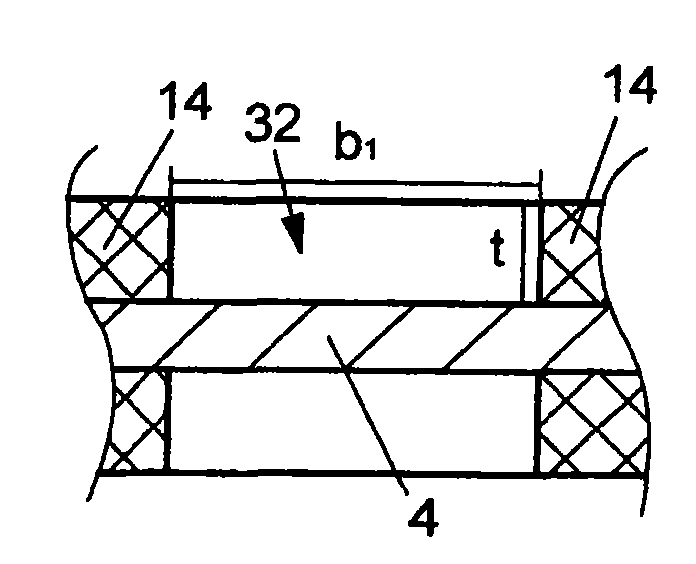

[0051] In each case, a friction lining 12 is arranged on the lining carrier 4 ( Figure 3 to Figure 5 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com