Air volume distribution structure for rail vehicle air supply passage

A rail vehicle and air supply duct technology, which is applied in the field of air volume distribution structures for rail vehicle air supply ducts, can solve the problem that the rail vehicle air duct cannot be turbulent and muffled, and achieve the effects of avoiding eddy currents and reducing interior noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

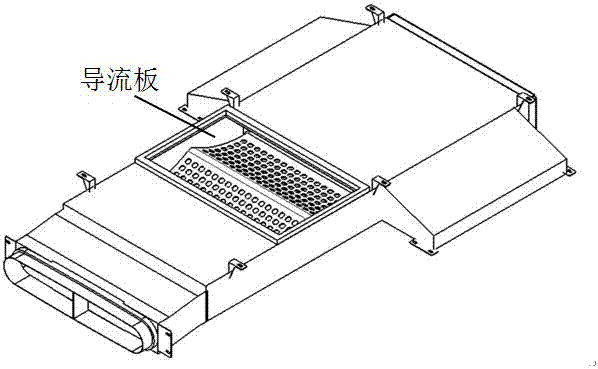

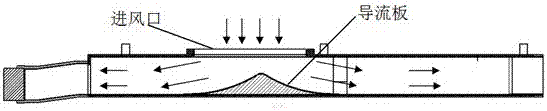

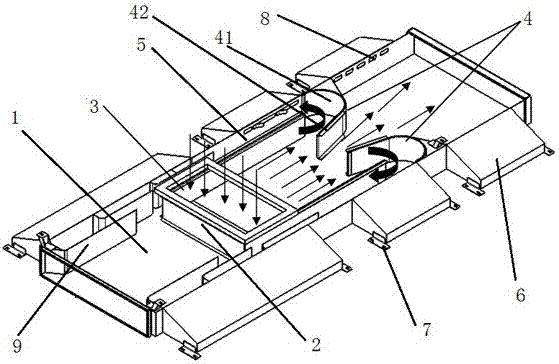

[0023] Such as image 3 As shown, the air volume distribution structure for the air supply channel of a rail vehicle includes a main air channel, and a plurality of air outlets are respectively arranged on both sides of the main air channel 1, and a horizontally arranged U Type plate 2, the upper and lower ends of the U-shaped plate 2 are respectively attached to the top and bottom pipe walls of the main air duct 1, the open end of the U-shaped plate 2 faces one end of the main air duct 1, and the two sides of the U-shaped plate 2 A side air duct 5 is formed between the main air duct 1 and the main air duct 1 is located on the top of the closed end of the U-shaped plate 2 with an air inlet 3, and the main air duct 1 is located in front of the opening end of the U-shaped plate 2. Two The deflectors 4 are symmetrically arranged, and the two deflectors 4 are respectively corresponding to the two side plates of the U-shaped plate 2. There is a gap between the two deflectors 4, and...

Embodiment 2

[0025] In order not to affect the air flow of the main air duct located at the rear of the U-shaped plate, the structure of the main air duct located at the rear of the U-shaped plate is improved. The specific structure is as follows:

[0026] The main air duct 1 is located at the rear of the closed end of the U-shaped plate 2 and is provided with two baffles 9 respectively aligned with the side panels on both sides of the U-shaped plate 2. Set the opening. After the air flow is guided to the side air duct 5 through the deflector 4, part of the air flow is discharged through the air outlet, but because the gas contained in the side air duct 5 is limited, and the exhausted air flow cannot keep up with the imported air flow, so through the A baffle 9 is provided at the rear of the side air duct, so that the airflow flows out from the branch air duct at the position of the baffle, and passes through the opening, and the excess air flows back to the opening position and enters the...

Embodiment 3

[0028] In order to ensure the effect of deflecting the air flow of the deflector, the structure of the deflector is further limited, and the specific structure is as follows:

[0029] The two deflectors 4 are respectively symmetrically installed on the side walls of the corresponding main air duct 1. The end faces of the deflectors 4 facing the side plates are arc-shaped concave surfaces 41, and the arc-shaped surfaces of the two deflectors 4 are The ends of the concave surface 41 are respectively provided with drain plates 42 extending toward the middle of the U-shaped plate 2, and the two drain plates 42 form a gap in a trumpet-shaped structure. The angle range is 30~40°, and the trumpet-shaped structure is used to divert air flow and adjust the forward and return air volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com