Composite material and preparation method thereof

A composite material and material technology, applied in the field of materials, can solve the problems of poor resistance to multiple elastics, fragility, etc., and achieve the effects of excellent ballistic performance, improved protection ability, good fixation and limiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] This embodiment also provides a method for preparing the above-mentioned composite material, comprising the steps of:

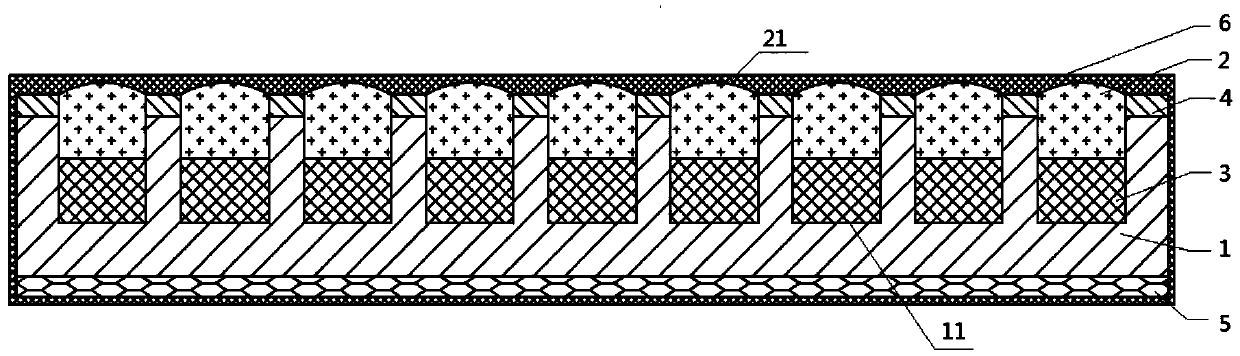

[0054] A. Drill flat-bottomed holes on the aluminum alloy substrate, and the flat-bottomed holes are evenly distributed on the upper surface of the aluminum alloy substrate. The thickness of the aluminum alloy substrate is 15-20mm, the diameter of the flat-bottomed holes is 13-15mm, the distance between the centers of adjacent flat-bottomed holes is 15-17mm, and the depth of the holes is 2 / 3 of the thickness of the aluminum alloy substrate.

[0055] B. Preparation of ceramic columns, rubber sheets, steel mesh and honeycomb panels. Using silicon carbide ceramics, the shape is cylindrical, the bottom is flat, and the top is provided with a spherical crown. The height of the spherical crown is 1.5mm, the diameter of the ceramic column is 13.02-15.04mm, and the height of the ceramic column is slightly higher than 1 / 2 of the depth of the flat-bottomed hole...

Embodiment 1

[0063] A preparation process of a composite board is as follows:

[0064] 1. Prepare a 15mm thick 7075 aluminum alloy substrate, and perform T6 heat treatment on the aluminum alloy substrate.

[0065] 2. Drill flat-bottomed holes on the aluminum alloy substrate, and the flat-bottomed holes are evenly distributed on the upper surface of the aluminum alloy substrate. The diameter of the flat-bottomed holes is 13mm, the distance between the centers of adjacent flat-bottomed holes is 15mm, and the hole depth is 10mm.

[0066] 3. Prepare a ceramic column, the material is silicon carbide, the diameter of the ceramic column is 13.02-13.04 mm, and the flat-bottomed hole meets the requirement of interference fit. The bottom of the ceramic column is flat, and the top is provided with a spherical cap. The height of the spherical cap is 1.5 mm, and the height of the ceramic column (excluding the spherical cap) is 6 mm.

[0067] 4. Prepare the rubber sheet, adopt butadiene rubber, its di...

Embodiment 2

[0077] A preparation process of a composite board is as follows:

[0078] 1. Prepare an 18mm thick 7075 aluminum alloy substrate, and perform T6 heat treatment on the aluminum alloy substrate.

[0079] 2. Drill flat-bottomed holes on the aluminum alloy substrate, and the flat-bottomed holes are evenly distributed on the upper surface of the aluminum alloy substrate. The diameter of the flat-bottomed holes is 15mm, the distance between the centers of adjacent flat-bottomed holes is 17mm, and the hole depth is 12mm.

[0080] 3. Prepare a ceramic column, the material is silicon carbide, the diameter of the ceramic column is 15.02-15.04 mm, and the flat-bottomed hole meets the requirement of interference fit. The bottom of the ceramic column is flat, and the top is provided with a spherical cap. The height of the spherical cap is 1.5 mm, and the height of the ceramic column (excluding the spherical cap) is 7 mm.

[0081] 4. A rubber sheet is prepared, using butadiene rubber, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com