Production method of soilless spray coating material

A technology for covering materials and production methods, applied in the direction of mixing methods, chemical instruments and methods, restoration of contaminated soil, etc., can solve problems such as unreasonable stirring forms, low mixing efficiency of plant fibers and other raw material components, and achieve improvement Adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The production method of the soilless spray coating material comprises the following steps:

[0031] (1) Prepare the following raw material components:

[0032]1kg of waterproofing agent, 6kg of thickener, 0.2kg of biological bacterial agent, 110kg of plant fiber, and 800kg of flame retardant; wherein the waterproofing agent adopts sodium methyl silicate waterproofing agent, the thickening agent adopts carrageenan, and the biological bacterial agent adopts bioremediation bacteria The raw material of plant fiber is a mixture of weeds and bark, and the flame retardant is halogen-free flame retardant polyamide.

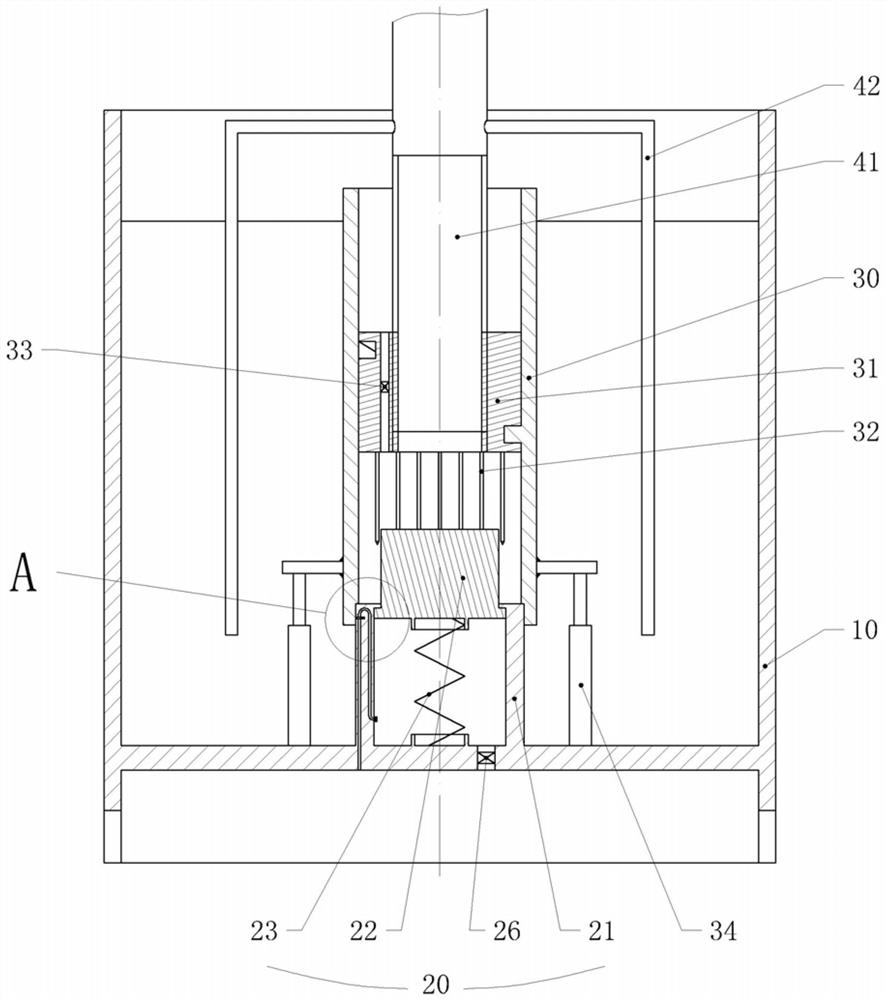

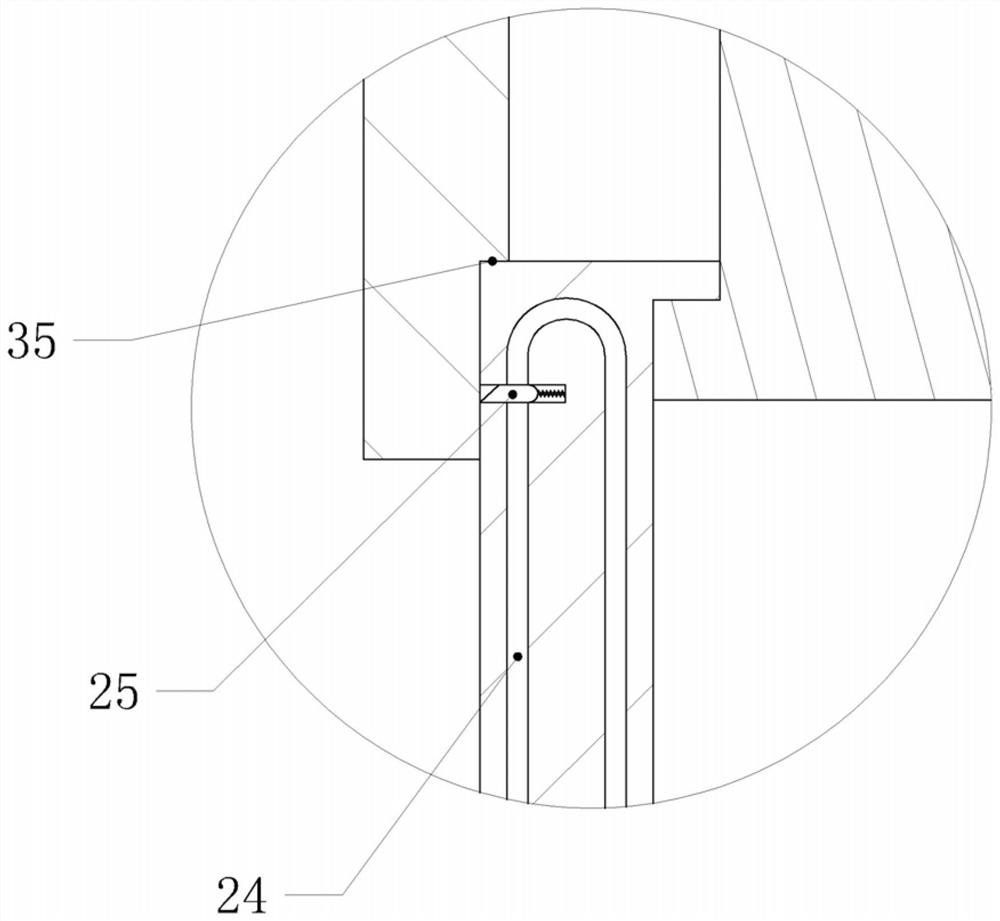

[0033] (2) The above raw materials are put into the stirring device, and an appropriate amount of water is added to stir evenly, and the amount of water is added to make the mixture material a viscous paste. In the present embodiment, the amount of water added is 300L. The batches are put into the mixing tank 10; after each raw material component is evenly stirre...

Embodiment 2

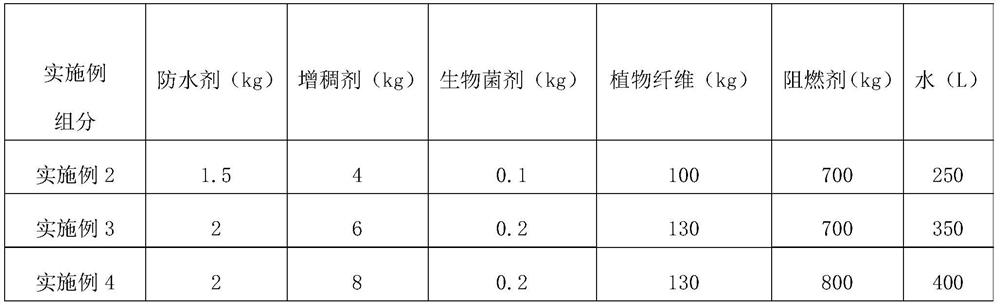

[0040] The difference between Example 2, Example 3 and Example 4 relative to Example 1 mainly lies in the difference in the ratio of raw materials, and its specific ratio is shown in the following table:

[0041]

[0042] In the above examples, the mixture of Example 2 is too viscous, while the viscosity of Examples 3 and 4 is low. The viscosity of the soilless spray coating material obtained in Example 1 is moderate, and its spraying is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com