Dynamic material thermometer

A thermometer and material technology, which is applied to the temperature measurement of moving fluids, instruments, thermometers, etc., can solve the problems of reducing product quality, low precision, and large temperature error of materials, and achieve real-time detection, improve detection accuracy, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

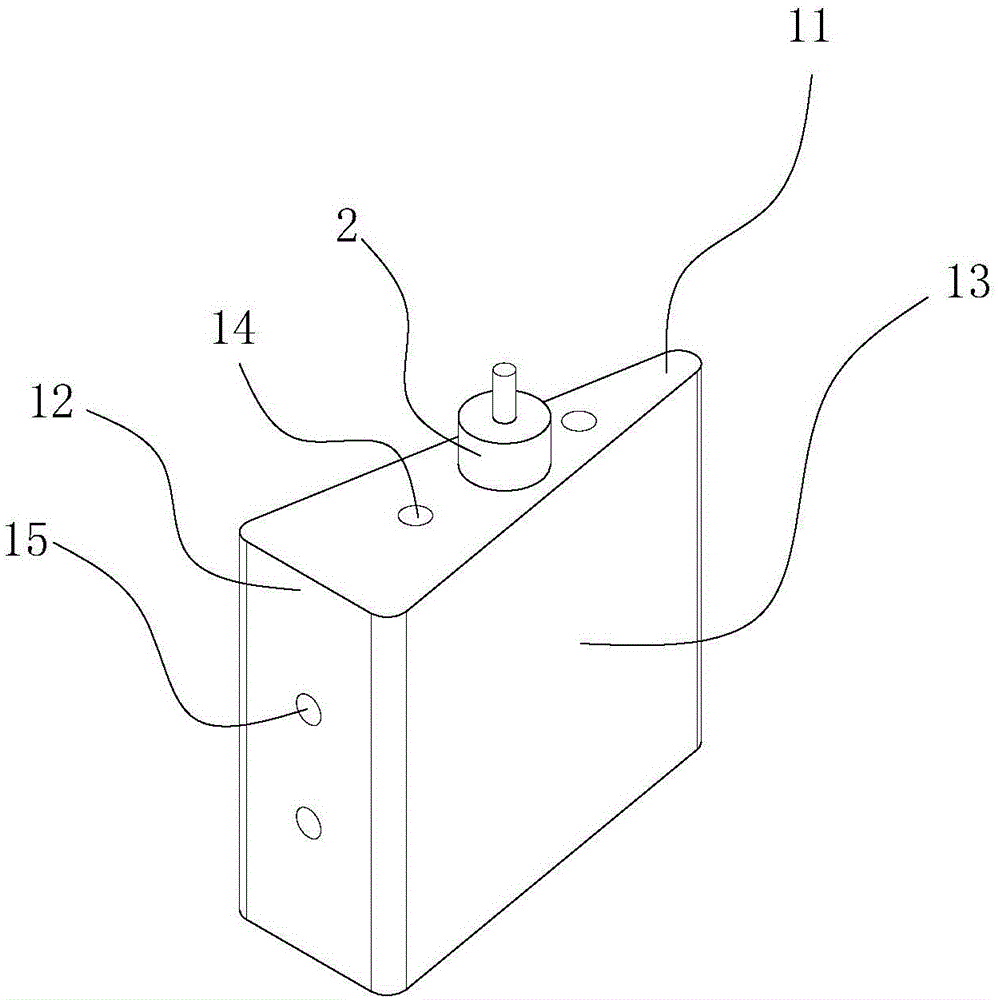

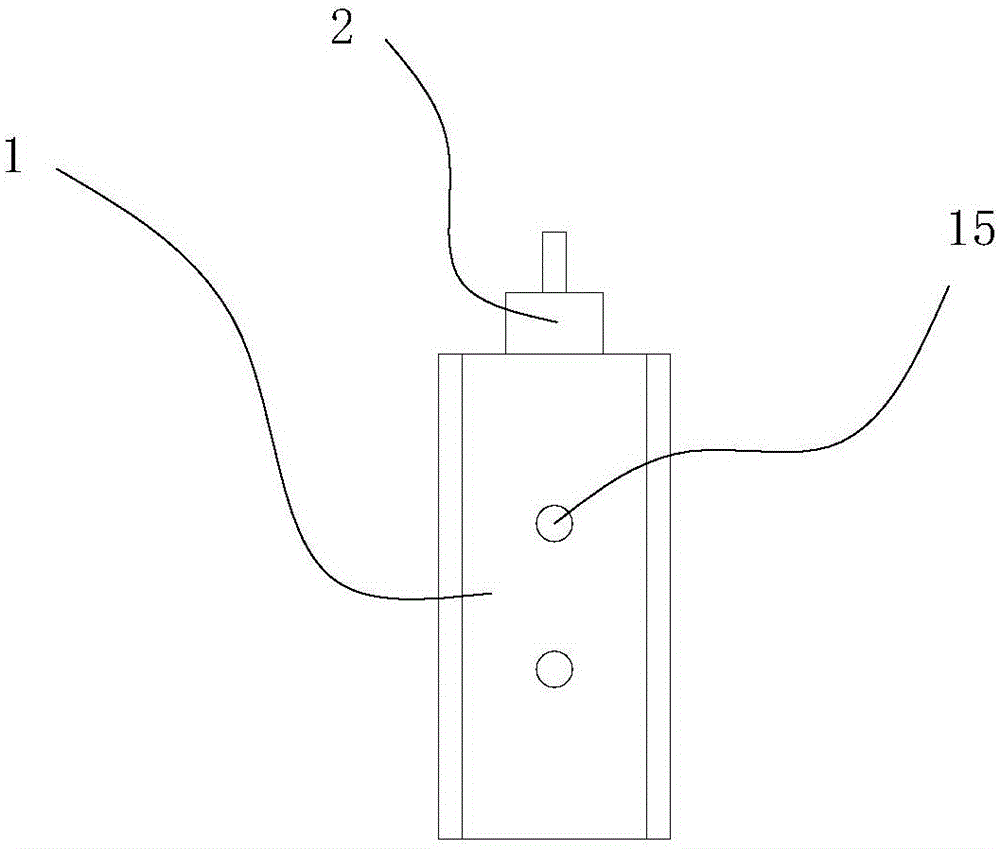

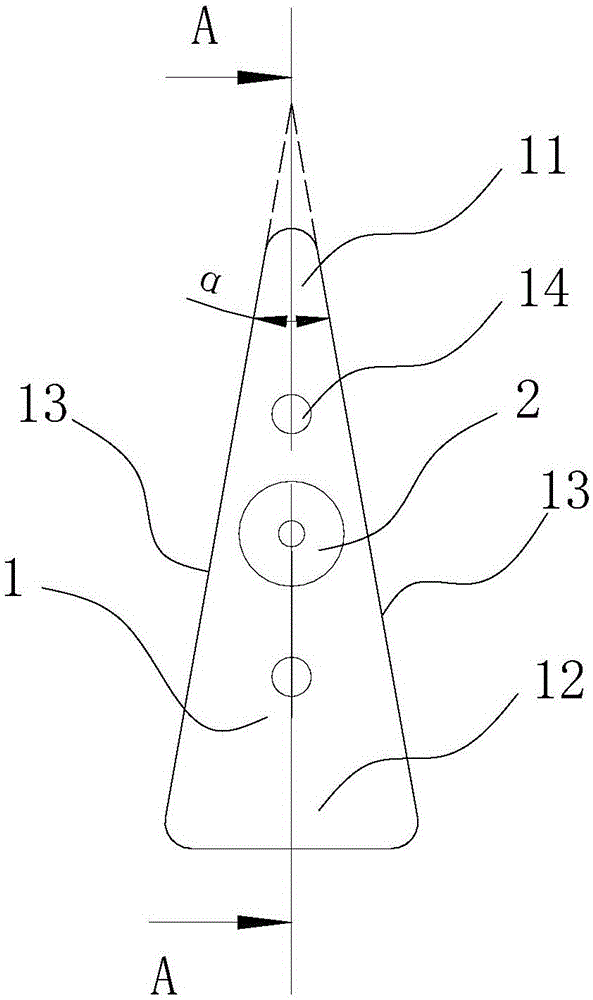

[0021] Such as Figure 1 to Figure 4 As shown, the dynamic material thermometer of the present invention includes a temperature sensor 2 and a heat conductor 1; the heat conductor 1 has a material feed end 11 and a discharge end 12; the material feed end 11 and the discharge end There are two material contact planes 13 between the ends 12; the two material contact planes 13 intersect to form the material feeding end 11; the two material contact planes 13 have an included angle α, 0<α<180°;

[0022] The temperature sensor 2 has a detection terminal 21 and a signal output terminal 22 ; the temperature sensor 2 is installed on the heat conductor 1 , and the detection terminal 21 of the temperature sensor 2 extends into the heat conductor 1 .

[0023] The detection end 21 of the temperature sensor 2 extending into the heat conductor 1 means that the detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com