Extraction process for improving recovery rate of fagaramides

A technology of anthracycline and extraction process is applied in the field of extraction process for improving the recovery rate of anthracycline, can solve problems such as low extraction rate, and achieve the effects of improving recovery rate and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

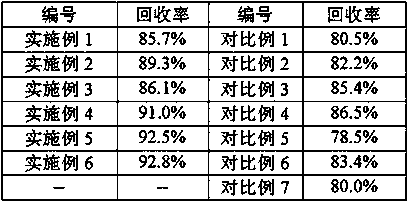

Examples

Embodiment 1

[0027] An extraction process for improving the recovery rate of anthocyanin, comprising the following steps:

[0028] (1) Pre-treatment of Zanthoxylum bungeanum: The raw material of Zanthoxylum bungeanum is pressed into tablets, the moisture content of the raw material of Zanthoxylum bungeanum is 10%, and the thickness of the tablet is 0.1mm;

[0029] (2) Supercritical CO 2 Fluid extraction: put the pepper flakes into the extraction tank, when the pressure of the extraction tank rises to 30MPa, and the extraction temperature is at 45°C, the supercritical CO 2 Fluid, pass entrainer at the same time, extract 3h, obtain extract;

[0030] (3) Separation: The extract enters the separation tank for separation, the separation pressure is 6MPa, and the separation temperature is 50°C to obtain Zanthoxylum bungeanum crude oil and gaseous CO 2 ;

[0031] (4) Molecular distillation treatment: the extracted crude oil of Zanthoxylum bungeanum is separated by molecular distillation techno...

Embodiment 2

[0034] An extraction process for improving the recovery rate of anthocyanin, comprising the following steps:

[0035] (1) Pre-treatment of Zanthoxylum bungeanum: The raw material of Zanthoxylum bungeanum is pressed into tablets, the moisture content of the raw material of Zanthoxylum bungeanum is 11%, and the thickness of the tablet is 0.3mm;

[0036] (2) Supercritical CO 2 Fluid extraction: put the pepper flakes into the extraction tank, when the pressure of the extraction tank rises to 32MPa and the extraction temperature is 48°C, supercritical CO 2 Fluid, pass entrainer at the same time, extract 3h, obtain extract;

[0037] (3) Separation: the extract enters the separation tank for separation, the separation pressure is 7MPa, and the separation temperature is 52°C to obtain Zanthoxylum bungeanum crude oil and gaseous CO 2 ;

[0038] (4) Molecular distillation treatment: the extracted crude oil of Zanthoxylum bungeanum is separated by molecular distillation technology, an...

Embodiment 3

[0041] An extraction process for improving the recovery rate of anthocyanin, comprising the following steps:

[0042] (1) Pre-treatment of Zanthoxylum bungeanum: Press the raw material of Zanthoxylum bungeanum into tablets, wherein the moisture content of the raw material of Zanthoxylum bungeanum is 12%, and the thickness of the tablet is 0.5mm;

[0043] (2) Supercritical CO 2 Fluid extraction: put the pepper flakes into the extraction tank, when the pressure of the extraction tank rises to 35MPa, and the extraction temperature is 50°C, the supercritical CO 2 Fluid, pass entrainer at the same time, extract 2.5h, obtain extract;

[0044] (3) Separation: The extract enters the separation tank for separation, the separation pressure is 8MPa, and the separation temperature is 55°C to obtain Zanthoxylum bungeanum crude oil and gaseous CO 2 ;

[0045] (4) Molecular distillation treatment: the extracted crude oil of Zanthoxylum bungeanum is separated by molecular distillation tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com