A turning/milling insert for processing special-shaped parts of high-hardness steel

A technology for special-shaped parts and milling blades, which is applied in the field of turning/milling blades for processing high-hardness steel special-shaped parts. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

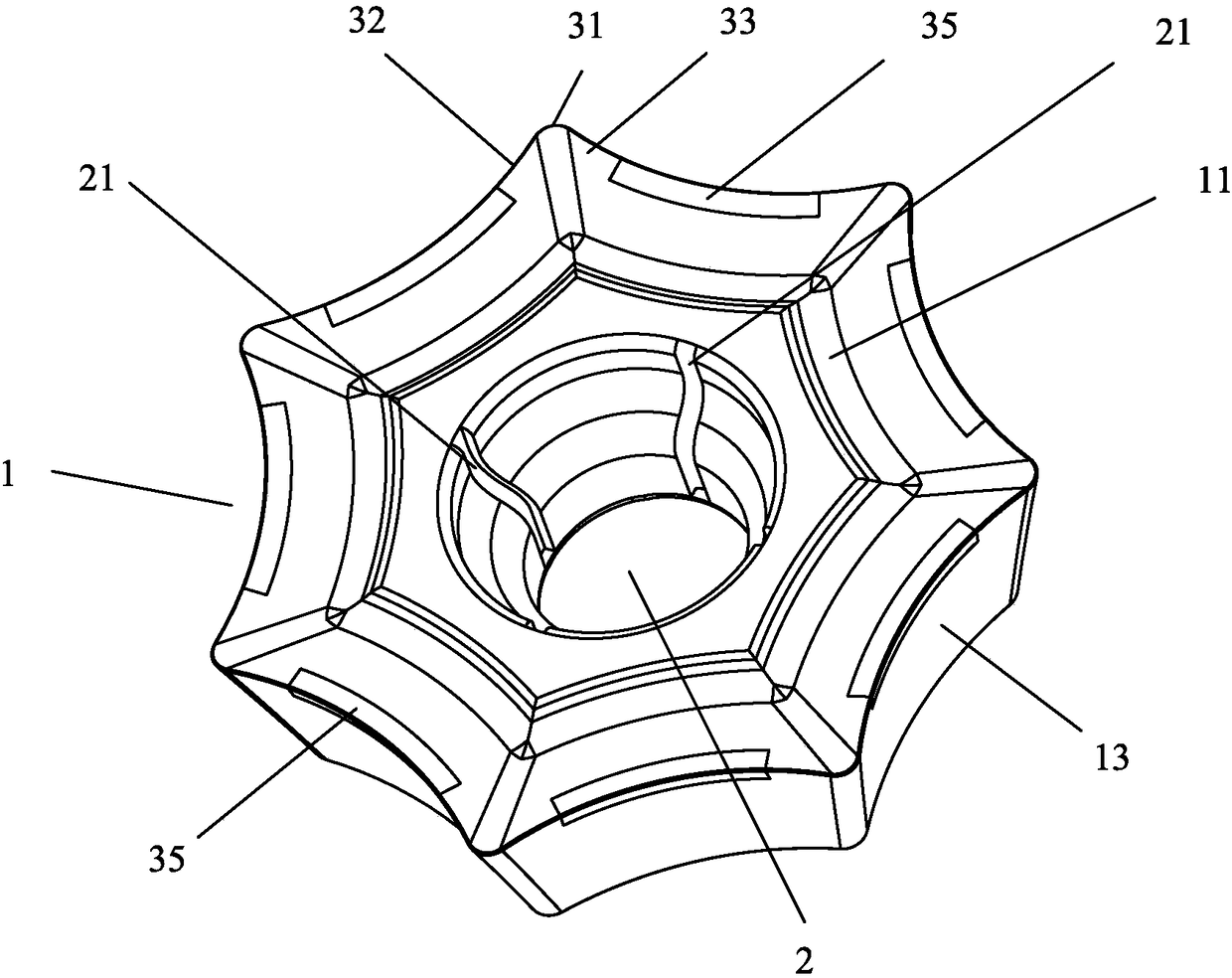

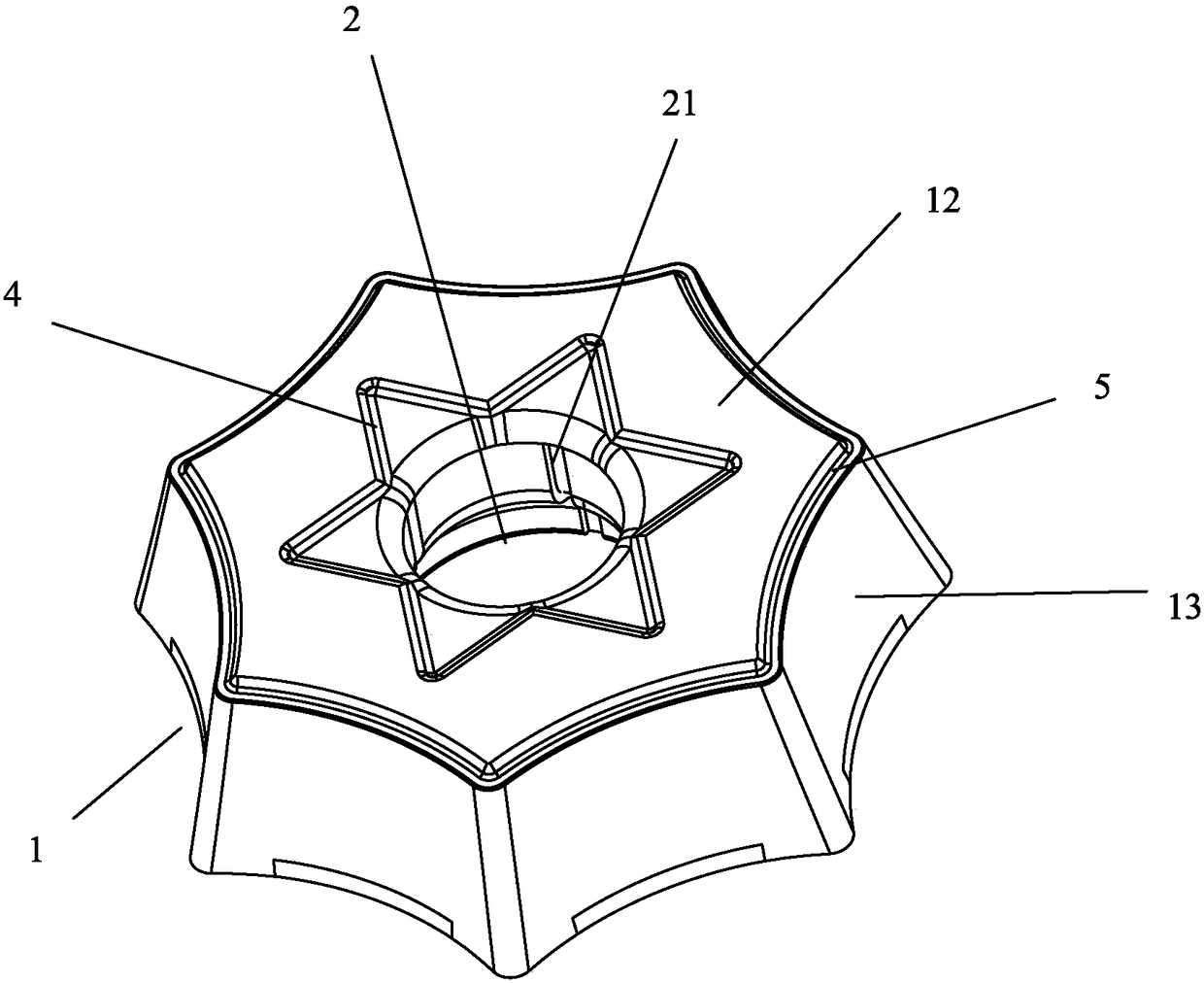

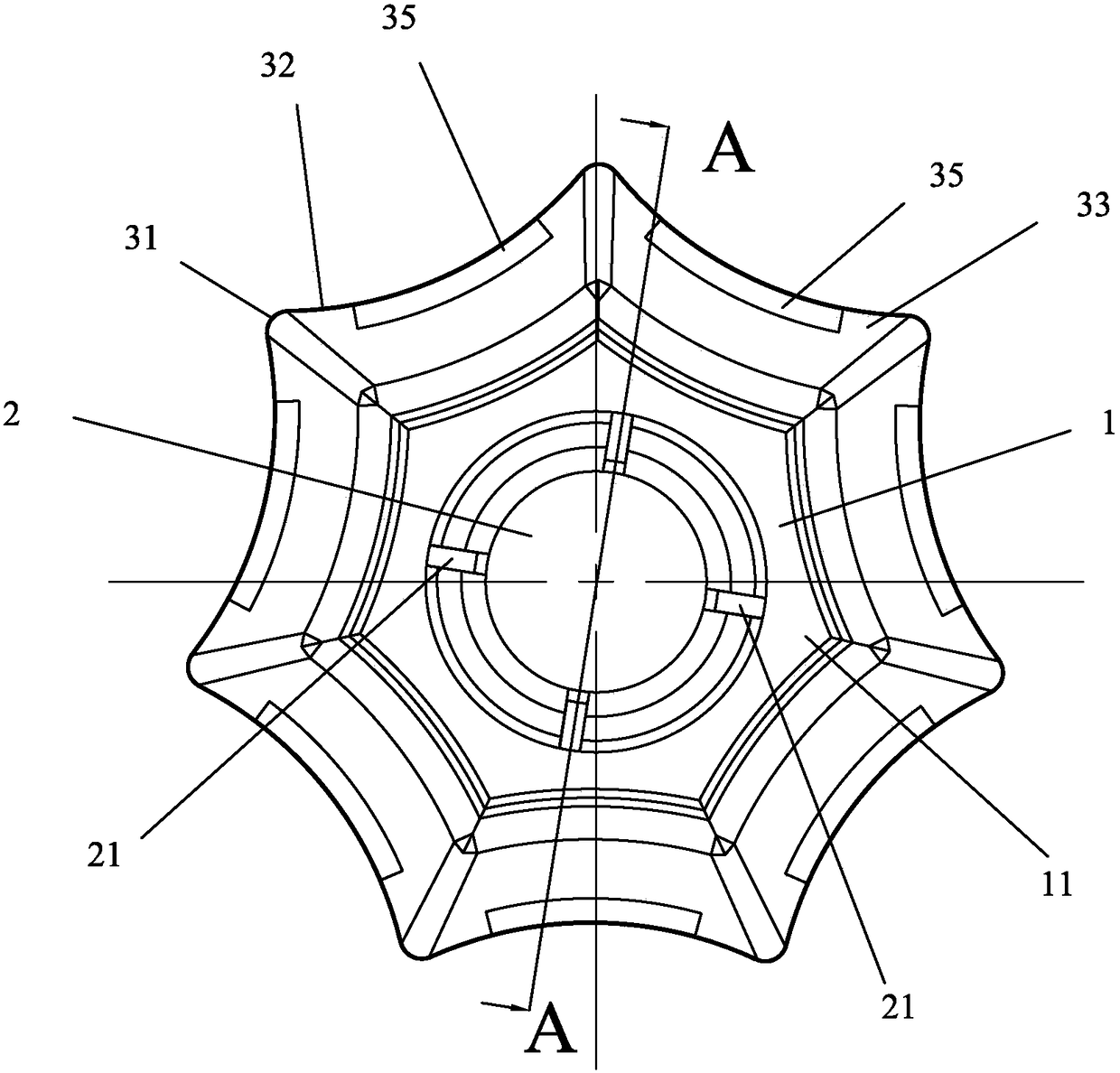

[0032] See Figure 1 to Figure 6 As shown, a turning / milling insert for processing high-hard steel special-shaped parts of the present invention includes a substantially heptagonal insert body 1; the insert body 1 has an upper surface 11, a lower surface 12, and a side surface 13; the insert The geometric center of the body 1 is provided with a fastening screw hole 2 penetrating through the upper and lower surfaces, so that the blade body 1 is fixed to the turning / milling cutter body by using the fastening screw hole 2; the upper surface of the blade body 1 The intersection line of 11 and the side 13 constitutes the cutting portion of the insert, which includes the tip 31 at the apex angle of the regular heptagon and the cutting edge at the side of the regular heptagon, and the cutting edge is curved inwardly. The cutting edge forms a fishtail-shaped cutting edge 32; the upper surface of the blade body 1 extends inward along the fishtail-shaped cutting edge to form a fishtail-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com