Scouring pad drawing wheel and manufacturing method thereof

A technology of scouring pad and scouring pad, applied in the field of wire drawing wheel and its preparation, can solve the problems of inconsistent processing surface effect, large grinding noise, weak cutting force, etc., achieve reasonable composition and ratio, and strong chip removal ability. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

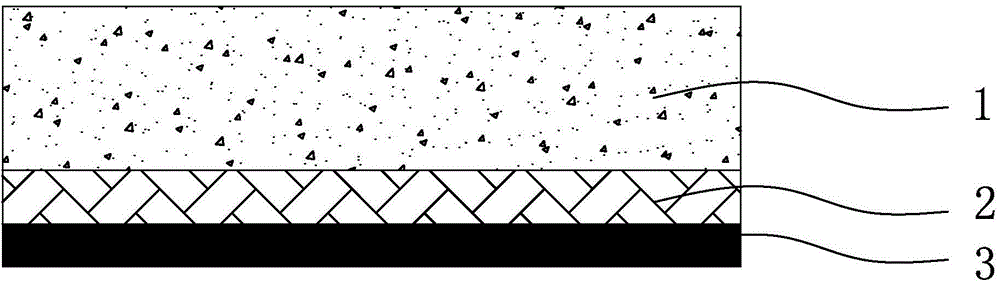

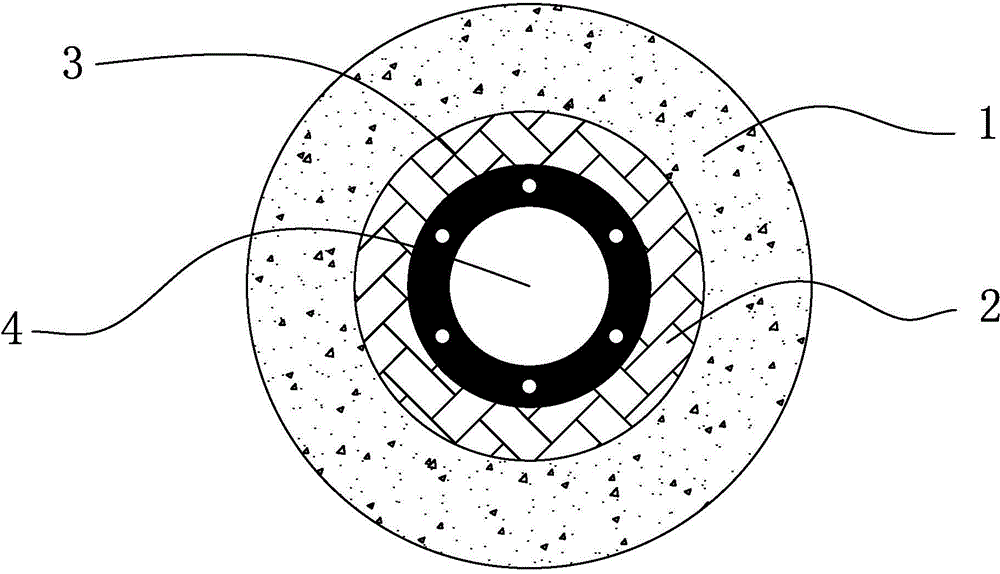

[0036] Substrate preparation: the substrate is made of engineering plastic polycarbonate with the prior art.

[0037] Reinforcement layer preparation: use glass fiber mesh as reinforcement material, impregnate the modified thermosetting resin diluent, put it into the mold, heat it in a hot press at a temperature of 120°C and a pressure of 18MPa for 5 minutes, and then shape it into a reinforcement layer.

[0038] Preparation of the scouring pad layer: the nylon material is made into a base fabric with a net-like three-dimensional structure through a spinning machine, and then nylon glue is sprayed on each surface of the base fabric. After spraying the nylon glue on each side, it needs to be baked at a temperature of 120°C for 8 minutes. The amount of spray glue is controlled at 1.8% of the mass of the base cloth. At the same time, weigh 100 parts of abrasive materials composed of 30% silicon carbide and 70% single crystal corundum in the corundum series, consisting of 3 parts ...

Embodiment 2

[0042] Substrate preparation: the substrate is made of engineering plastic polycarbonate with the prior art.

[0043] Reinforcement layer preparation: use glass fiber mesh as the reinforcement material, roll-coat the modified thermosetting resin diluent, stack two layers and put it into the mold, heat it in a hot press at a temperature of 130°C and a pressure of 20MPa for 5 minutes, Shape into strengthening layers.

[0044] Preparation of scouring pad layer: The nylon material is made into a base fabric with a mesh-like three-dimensional structure through a spinning machine, and then coated with nylon glue on each surface of the base fabric. After the nylon glue is coated on each side, it needs to be baked at a temperature of 130 ° C. After 5 minutes, the amount of glue applied was controlled at 1.9% of the mass of the base fabric. At the same time, weigh 100 parts of abrasives composed of 40% silicon carbide and 60% zirconium corundum in the corundum series, 4 parts of hemih...

Embodiment 3

[0048] Substrate preparation: the substrate is made of engineering plastic polycarbonate with the prior art.

[0049] Reinforcement layer preparation: use glass fiber mesh as the reinforcement layer material, impregnate the modified thermosetting resin diluent, stack three layers and put it into the mold, heat it in a hot press at a temperature of 160°C and a pressure of 22MPa for 4 minutes. , shaped into a reinforced layer.

[0050] Preparation of the scouring pad layer: the nylon material is made into a net-like three-dimensional base fabric through a spinning machine, and then nylon glue is sprayed on each surface of the base fabric. After spraying the nylon glue on each side, it needs to be baked at a temperature of 140°C for 5 minutes. The amount of spray glue is controlled at 1.9% of the mass of the base fabric. At the same time, weigh 100 parts of abrasives composed of 50% silicon carbide and 50% semi-brittle corundum in the corundum series, consisting of 4 parts of he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com