Heat-resistant alloy high-efficiency milling cutter

A technology for milling cutters and heat-resistant alloys, which is applied in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of reduced machining accuracy, low machining efficiency, and low machining life, and achieves improved milling strength and accuracy. Good cooling effect , The effect of long processing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

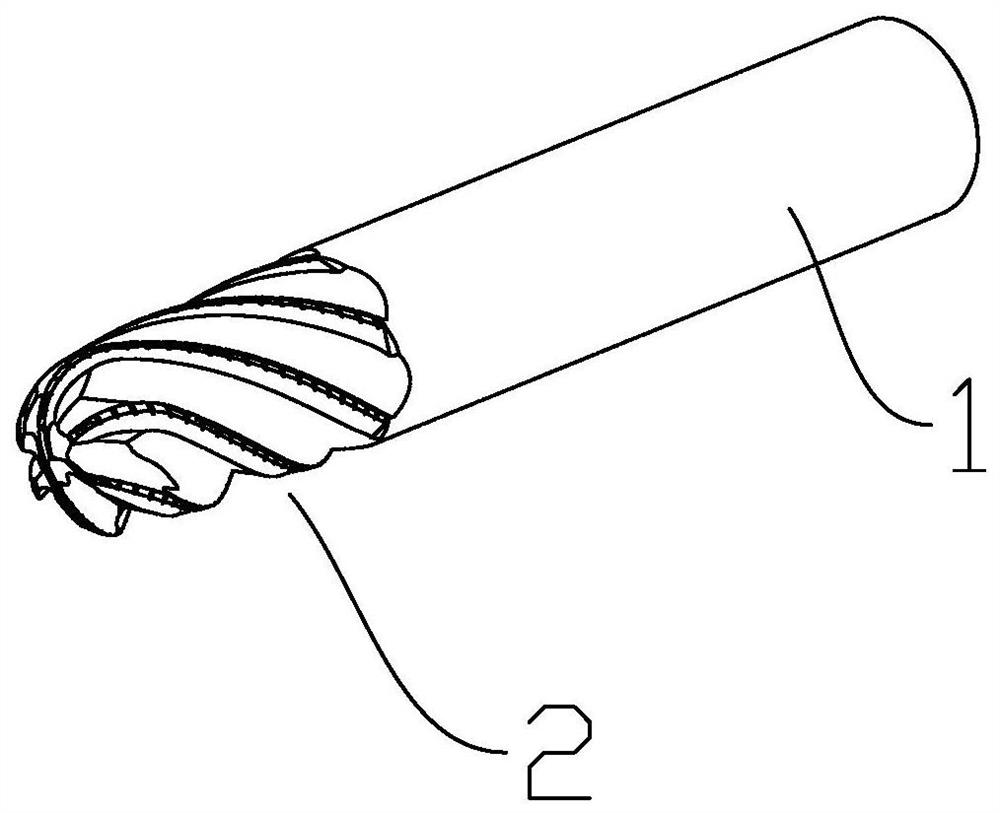

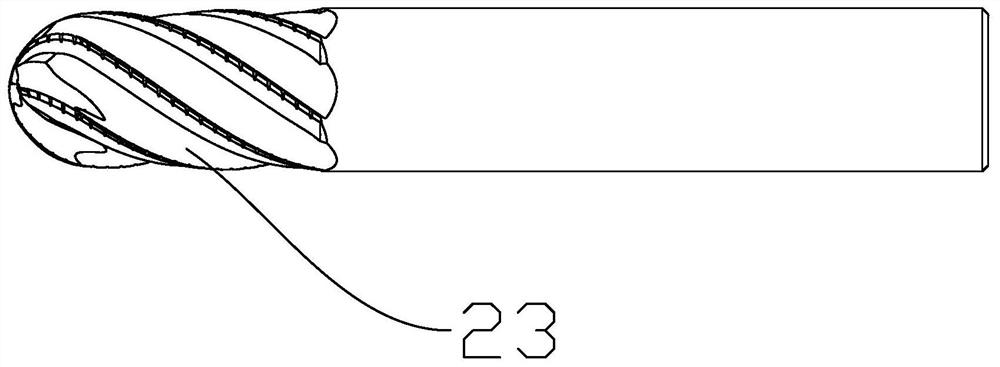

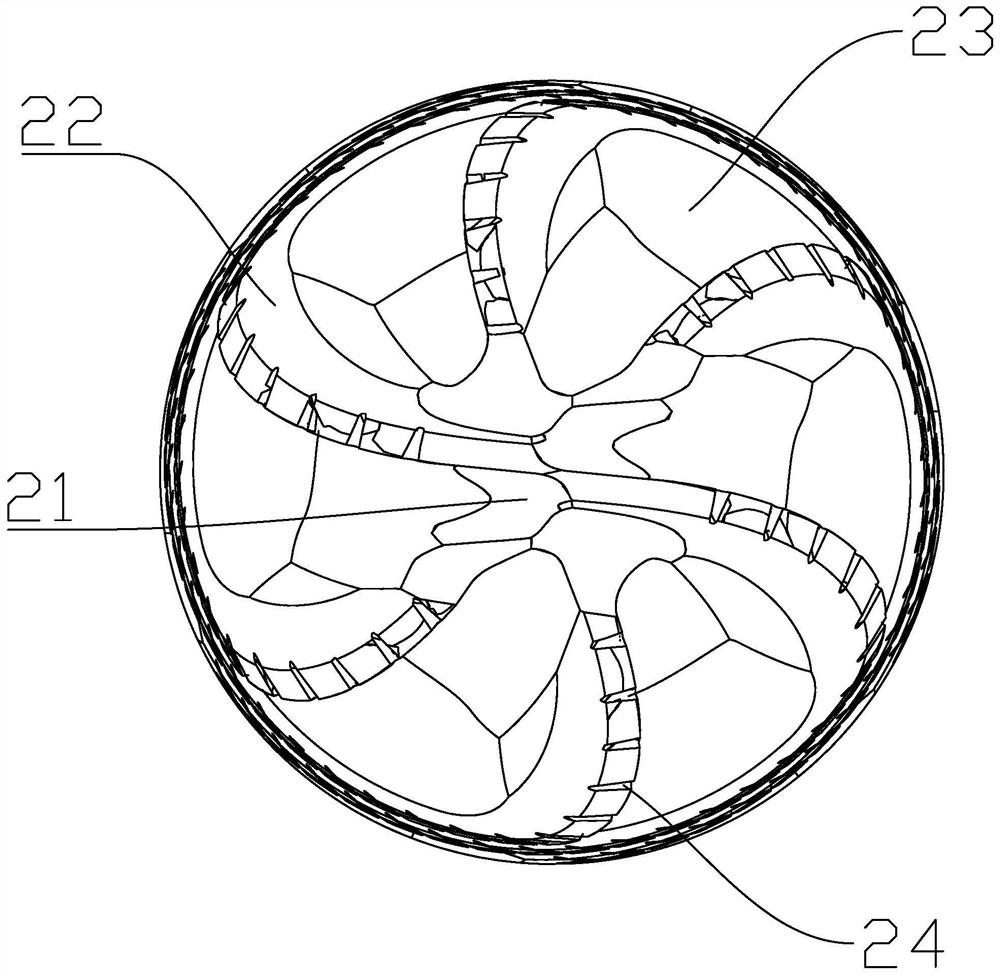

[0021] Embodiment 1, a heat-resistant alloy high-efficiency milling cutter, including a cutter bar, is characterized in that: one end of the cutter bar is formed with a cutter head, and the cutter head is formed with a central boss, and is provided with a cutting edge and a chip removal groove , the central boss is fixedly connected to the center of the cutter bar, the central boss is coaxially arranged with the cutter bar, and the cutting edges include at least four, and the cutting edges are evenly distributed on the side circumference of the central boss and are formed by the The central boss is arranged in the center circle, the chip removal groove is set between the two cutting edges, the top of the central boss is the base surface, and every two cutting edges symmetrical to the central axis of the central boss on the base surface are S shape, the cutting edge and chip flute extend to the side of the tool holder in the same helical direction, and the cutting edge and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com