Turning/milling blade for machining dead-hard steel special-shaped part

A technology for special-shaped parts and high-hard steel, which is applied in the field of turning/milling blades for processing high-hard steel special-shaped parts. It can solve problems such as inability to meet comprehensive processing requirements, increase effective heat dissipation area, increase strength, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

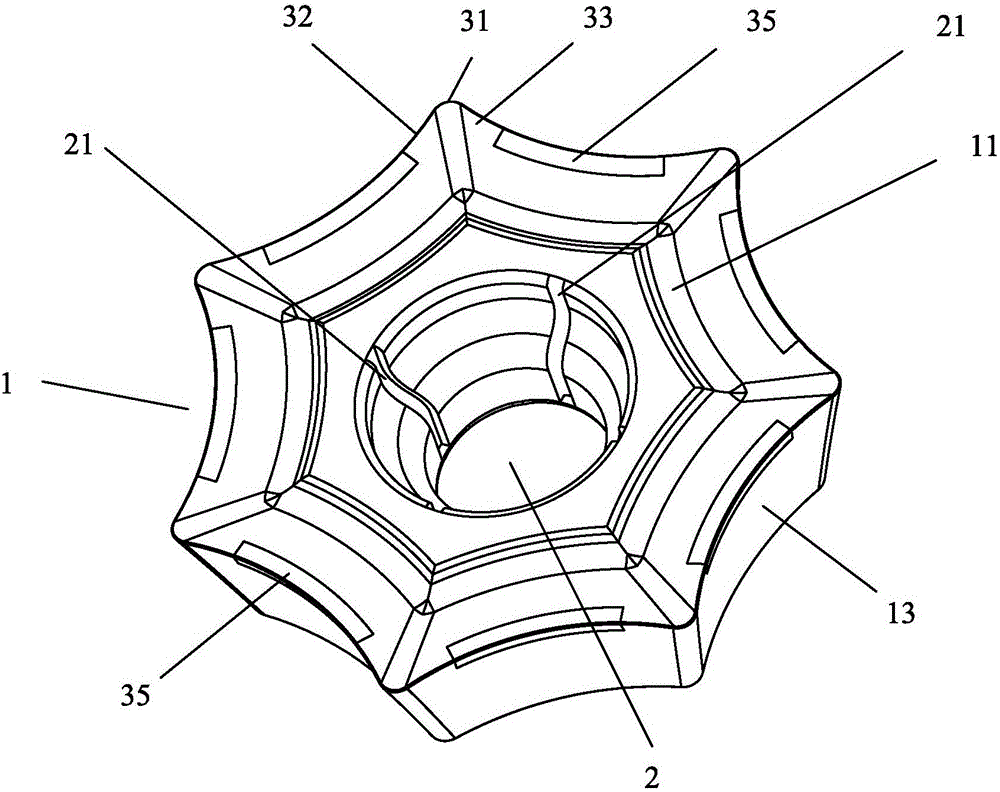

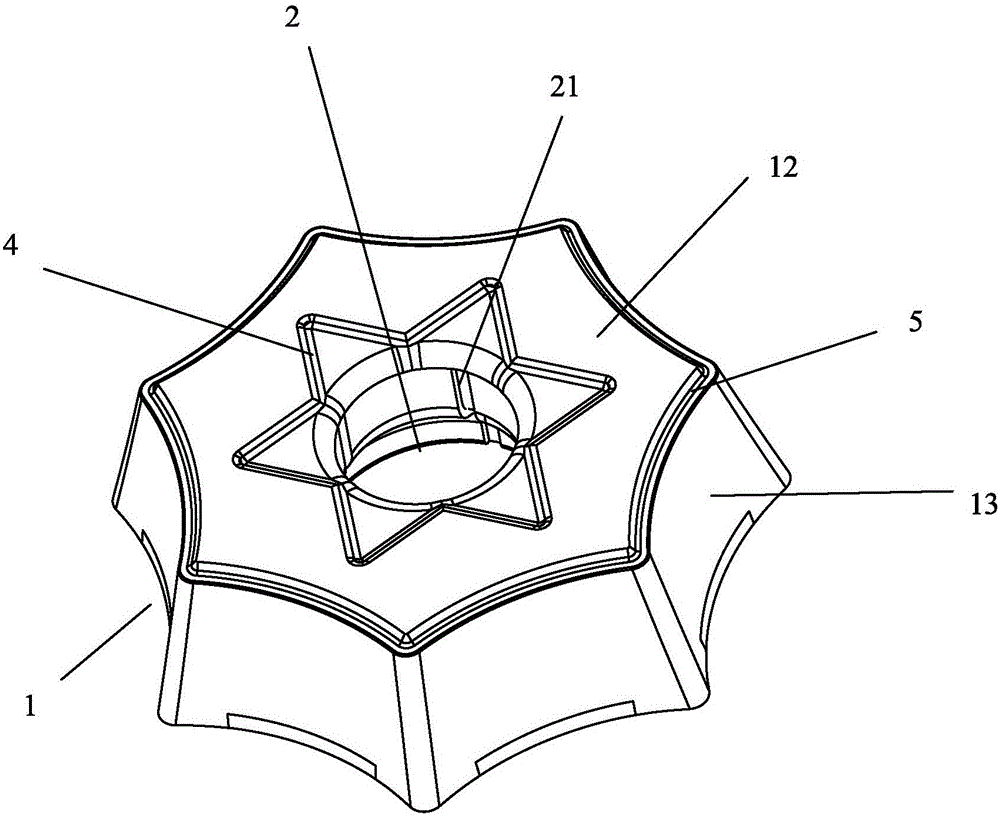

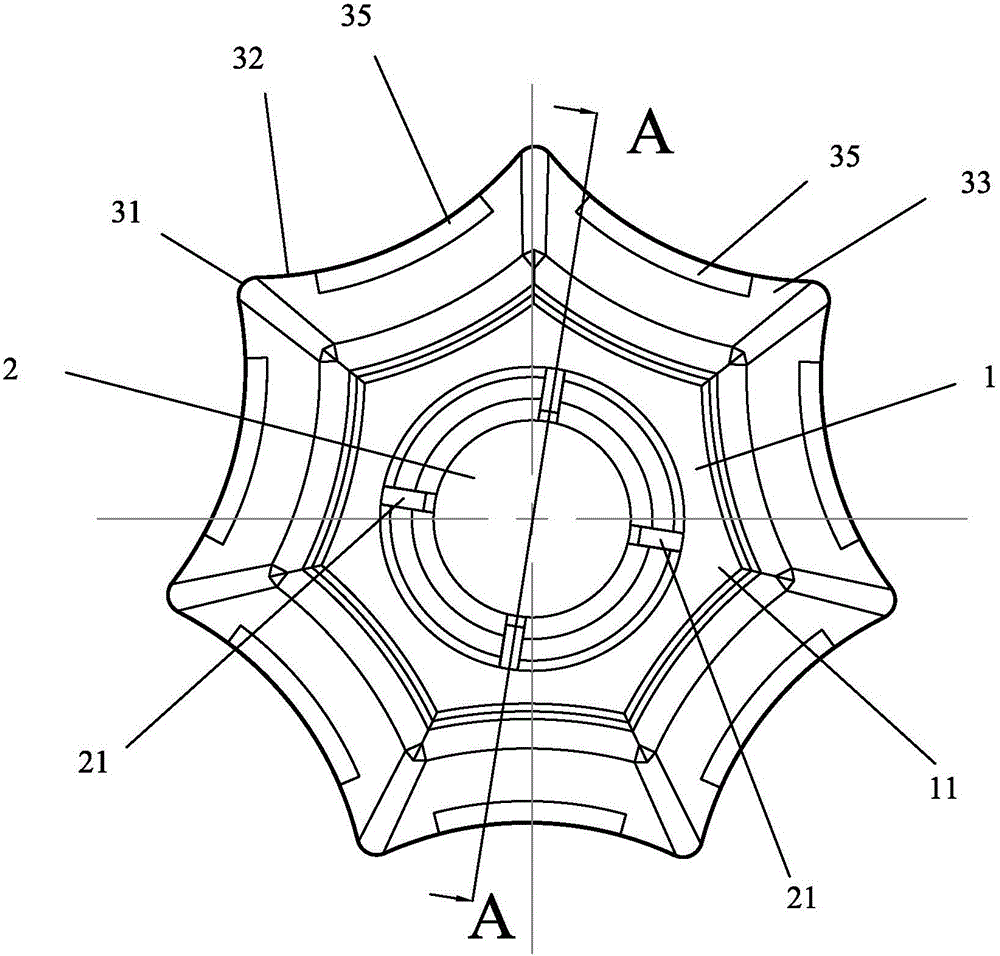

[0032] see Figure 1 to Figure 6 As shown, a turning / milling insert for processing high-hardness steel special-shaped parts of the present invention includes a roughly regular heptagonal insert body 1; the insert body 1 has an upper surface 11, a lower surface 12 and a side surface 13; the insert The geometric center of the body 1 is provided with a fastening screw hole 2 through the upper and lower surfaces, so as to use the fastening screw hole 2 to fix the blade body 1 on the turning / milling cutter body; the upper surface of the blade body 1 The intersection line of 11 and side 13 constitutes the cutting portion of the blade, which includes a cutting edge 31 at the vertex of the regular heptagon and a cutting edge at the side of the regular heptagon, and the cutting edge is curved inwardly. The cutting edge forms a fishtail-shaped cutting edge 32; the upper surface of the insert body 1 extends inwardly along the fishtail-shaped cutting edge to form a fishtail-shaped rake fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com