Lubricant composition for cutting machining of ordinary carbon structure steel gear

A technology of lubricant composition and carbon structural steel, applied in the direction of lubricant composition, petroleum industry, etc., can solve the problem of easy formation of lubricating oil film, etc., and achieve the effect of strong chip removal ability, good cooling performance, and reduction of accumulation.

Inactive Publication Date: 2017-02-22

GUANGXI UNIV

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The working conditions of cutting oil and ordinary lubricating oil are different. Ordinary lubricating oil is between the constant friction surfaces that move repeatedly. Although there is a lot of pressure, it is easy to form a lubricating oil film.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

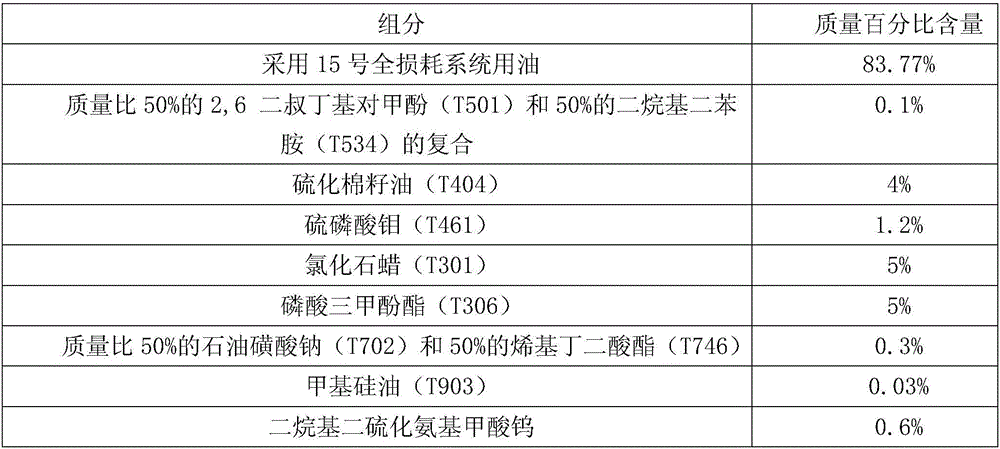

Embodiment 3

[0027] The following components are blended according to mass percentage:

[0028]

[0029] Example 3 product typical technical index:

[0030] project index Kinematic viscosity at 40℃mm 2 / s

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses lubricant composition for cutting machining of an ordinary carbon structure steel gear. No.15 total loss system oil is adopted as base oil and matched with multiple composite additives including an antioxidant, an oily agent, a friction modifier, an extreme pressure agent, an antiwear agent, an antirust agent, an anti-foaming agent and an oxidation and corrosion inhibitor. The composition is good in cooling performance, lubricating property, cleaning performance and diffusibility and high in chip removal capacity, can reduce phenomena such as accumulated burl, scratching and bruising produced during machining and has the advantages of resisting wear, reducing friction and preventing rust.

Description

technical field [0001] The invention belongs to the field of cutting processing of carbon steel gears, and in particular relates to a lubricant composition for cutting processing of ordinary carbon structural steel gears. Background technique [0002] Ordinary carbon structural steel is also called ordinary carbon steel. The carbon content is 0.06-0.22%, and less than 0.25% is the most commonly used. Belonging to low-carbon steel, each metal grade indicates the lowest yield point of the steel when the thickness is less than 16mm. my country and some countries divide ordinary carbon steel into three categories according to the delivery guarantee conditions: Class A steel (Class A steel), which only guarantees mechanical properties, but does not guarantee chemical composition, Class B steel (Class B steel), Only the chemical composition is guaranteed, but the mechanical properties are not guaranteed; special steel (C-type steel) not only guarantees the chemical composition, b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04C10N30/06C10N30/04C10N30/12C10N40/22

CPCC10M169/048C10M2201/085C10M2207/026C10M2207/282C10M2211/08C10M2215/064C10M2219/044C10M2219/068C10M2223/041C10M2229/041C10N2030/04C10N2030/06C10N2030/12C10N2030/68C10N2040/22C10N2010/12C10N2010/02

Inventor 黄福川赵金城黄显昆

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com