Drill bit

A drill bit and drill body technology, which is applied in the direction of drill repair, drill tool accessories, drilling/drilling equipment, etc., can solve the problems of debris reducing the chip removal capacity of the drill bit, reducing the service life of the drill bit, and the drill tip is prone to high temperature, etc. Achieve the effect of obvious guiding effect, increase the adhesion area, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

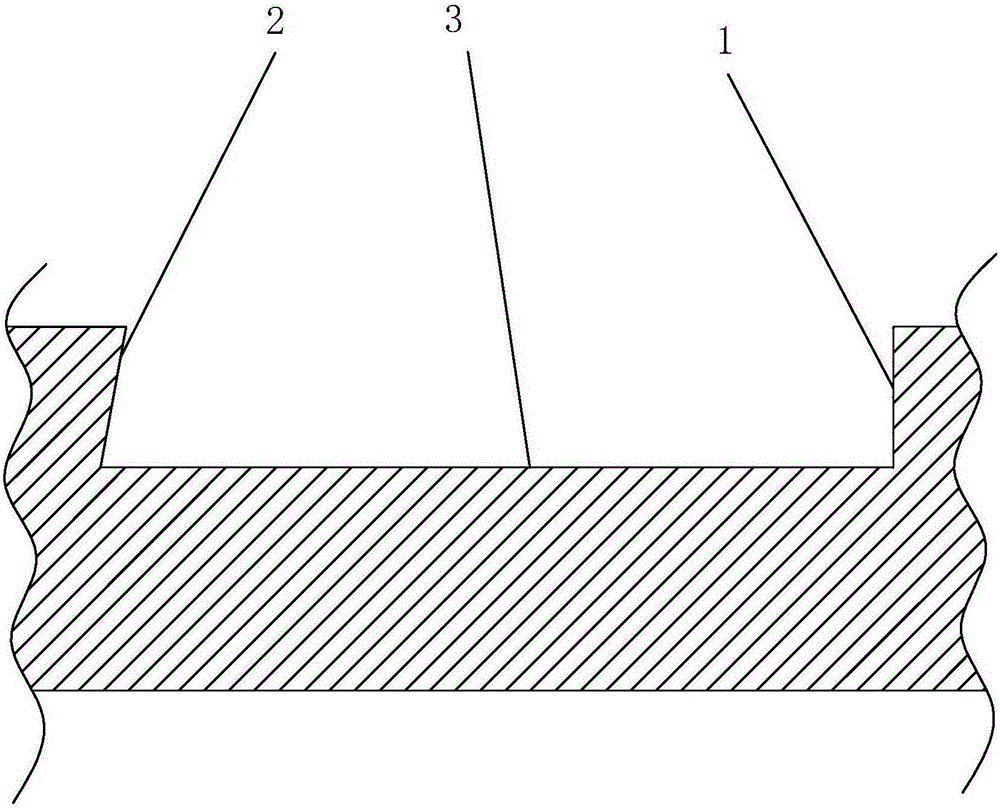

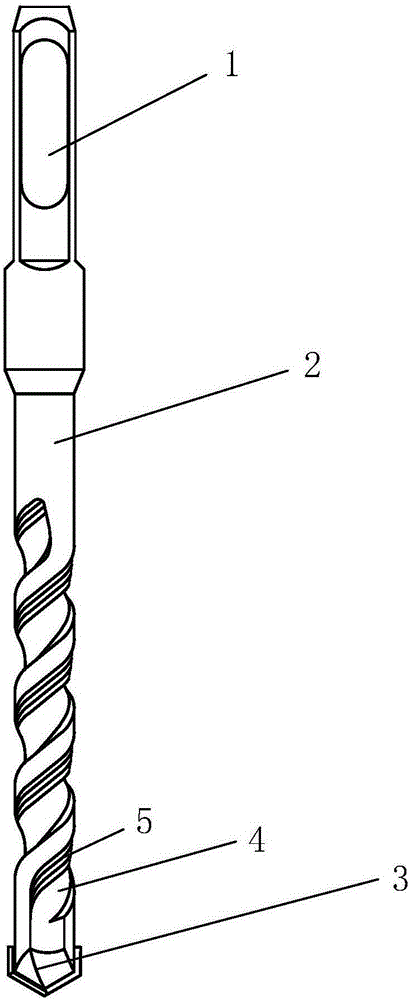

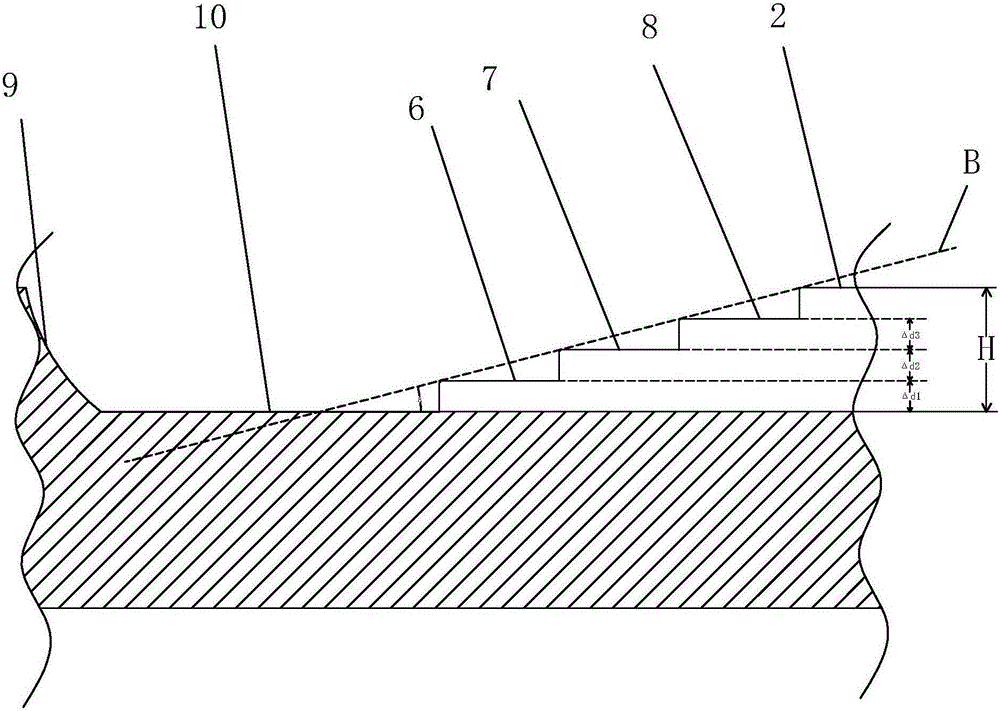

[0025] Refer to attached Figure 2-3 As shown, a drill bit includes a drill shank 1, a drill body 2 and a drill tip 3, a helical chip guide 4 is provided on the drill body, and a concave arc surface 9 is formed on the left side wall of the helical chip guide 4.

[0026] On the bottom surface 10 of the spiral chip guide, there is a chip guide portion 5 formed by flange I6, flange II7 and flange III8. The left side wall of flange I6 coincides with the spiral center line of the spiral chip guide groove 4, the right side wall of flange I6 coincides with the left side wall of flange II7, and the right side wall of flange II7 coincides with the left side of flange III8 The walls coincide, and the left side wall of the flange III8 coincides with the right side wall of the spiral chip guide groove 4. The flange I6 , flange II7 and flange III8 extend from the starting position of the spiral chip guide 4 along the direction of the spiral chip guide 4 to the end position of the spiral c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com