A rare earth permanent magnetic material preparing method

A rare-earth permanent magnet and residual material technology, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of magnetic powder compact oxidation, fusion, combustion, etc., and achieve short holding time, high utilization rate, and sintering energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0077] The rare earth permanent magnet material used in the specific embodiment of the present invention is R-T-B, R is at least one element selected from rare earth elements and Y, T is a transition metal element including Fe, and B is boron.

[0078] Preferably, the alloy comprises 26-31wt% of Nd and / or Pr, 0-5wt% of Dy, 0-1wt% of Co, 0-0.5wt% of Nb, 0-0.2wt% of Al, 0-0.2 Wt% Cu, B 0.9-1.1wt%, balance Fe.

[0079] The R-T-B rare earth permanent magnet material was prepared by the following preparation method.

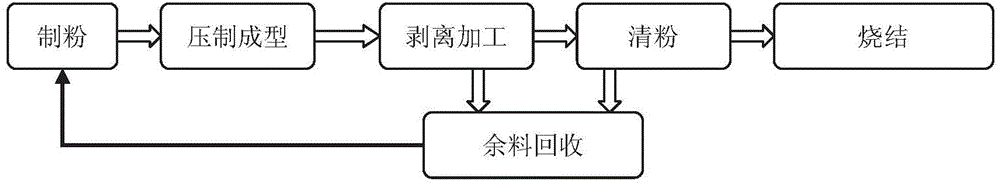

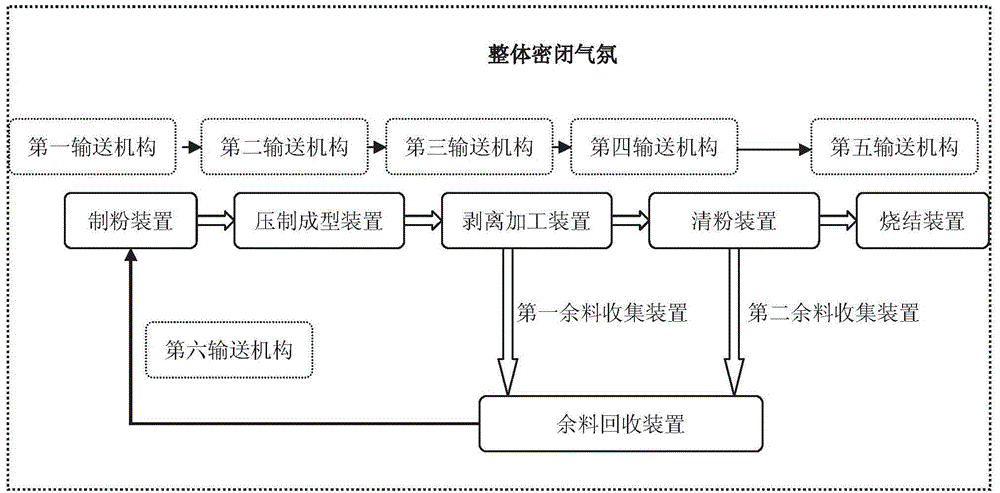

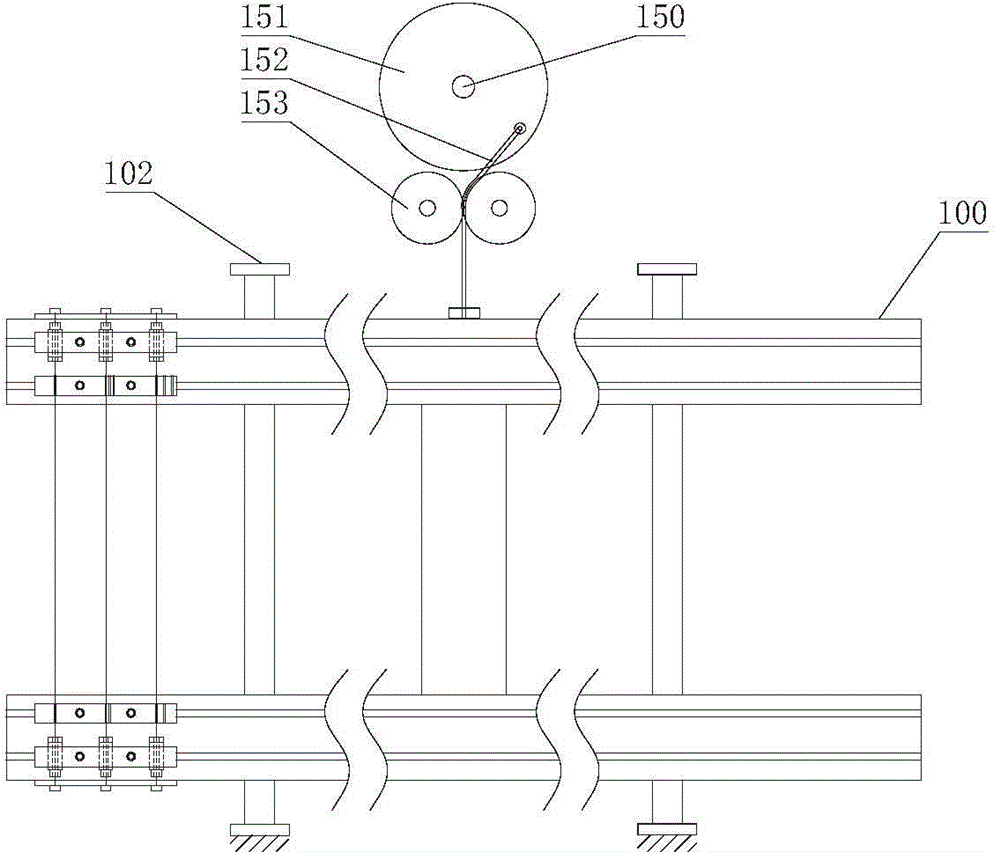

[0080] Such as Figure 1-2 As shown, firstly, the casting sheet of R-T-B rare earth permanent magnet material is prepared by the known rapid quenching technology, which specifically includes: melting the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com