An anchoring method for a bolt

An anchoring method and technology of anchor rods, which are applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of reduced bearing capacity, insufficient hole wall strength, safety accidents, etc., achieve large cutting force and increase axial tensile resistance Ability, avoid stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

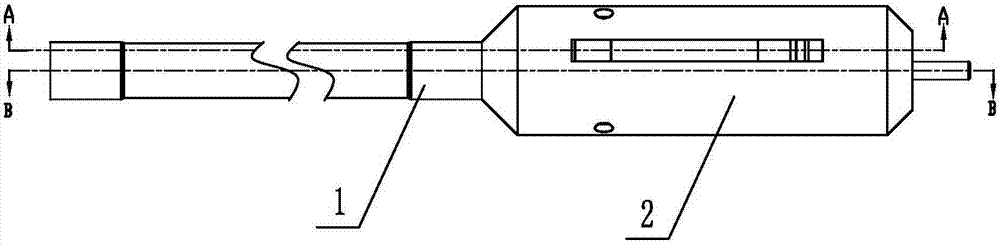

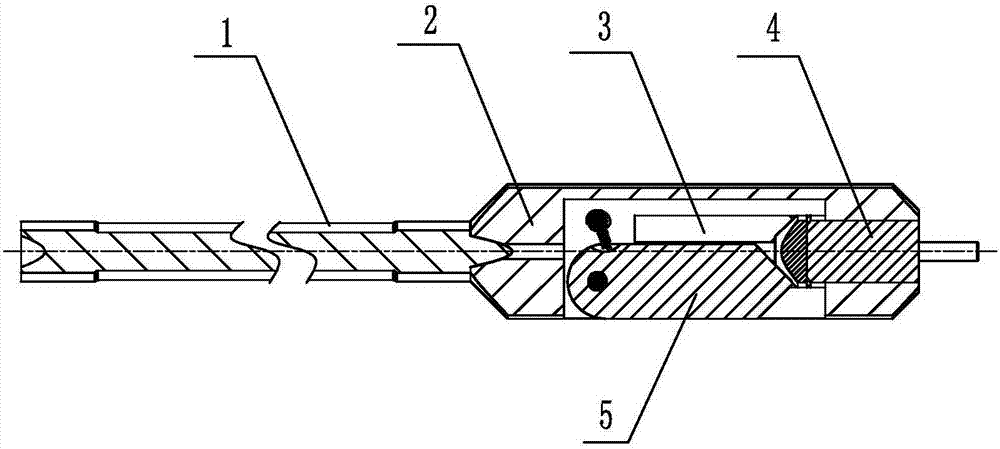

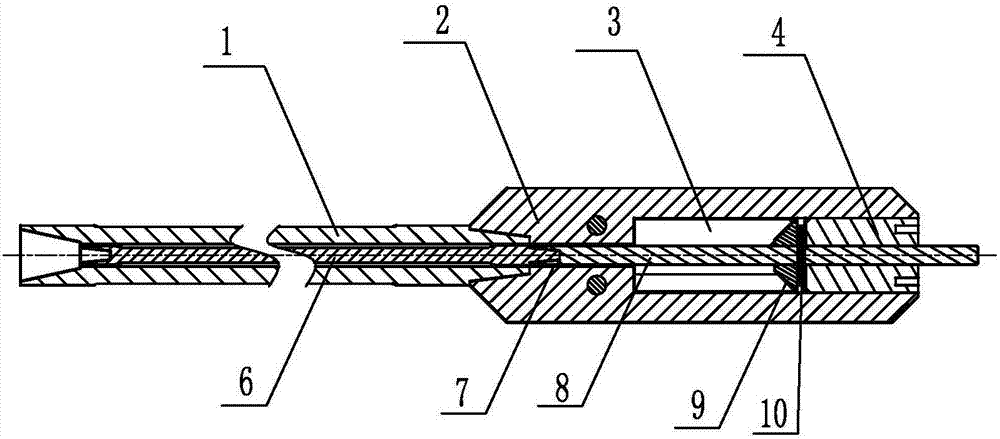

[0024] Such as Figure 1 to Figure 13 Shown, the anchoring method of a kind of invented anchor rod of the present invention, comprises the following steps:

[0025] (1) Pre-drill a pre-drilled hole 15 with a consistent diameter in the rock wall with a common drill bit;

[0026] (2) Connect the reaming head to the anchor drill, let the anchor drill (not shown in the figure) connect the inner and outer rods of the reaming head, and extend the reaming head into the pre-drilled hole 15 , so that the outer cover of the reaming head equipped with a knife plate is located at the position where the hole needs to be enlarged;

[0027] (3) Control the anchoring rig to pull the inner rod so that the knife plate 5 protrudes from the knife plate receiving groove 11 to the outer surface of the jacket, and press the fluid (usually water) into the space between the inner and outer rods through a pump (not shown in the figure) In the liquid diversion channel 7, let the fluid go to the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com