Mooring cable and manufacturing method thereof

A manufacturing method and mooring wire technology, which are applied in the manufacture of cables/conductors, cables, insulated cables, etc., can solve problems such as failure to work normally, and achieve improved axial tensile strength, improved bending resistance, and strong bending resistance. effect on axial tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

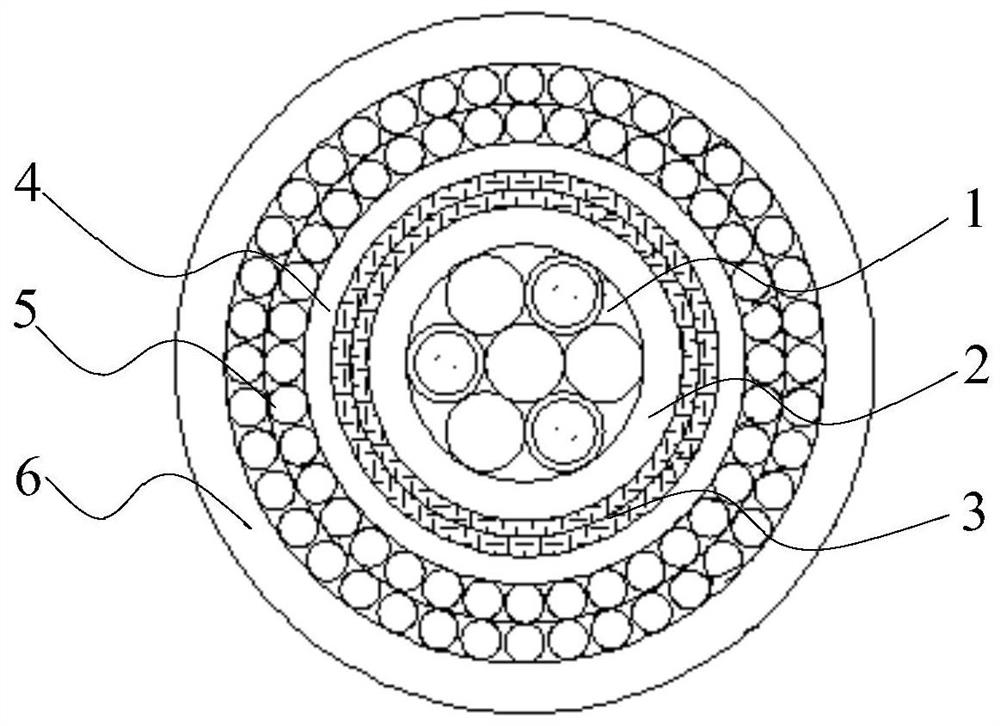

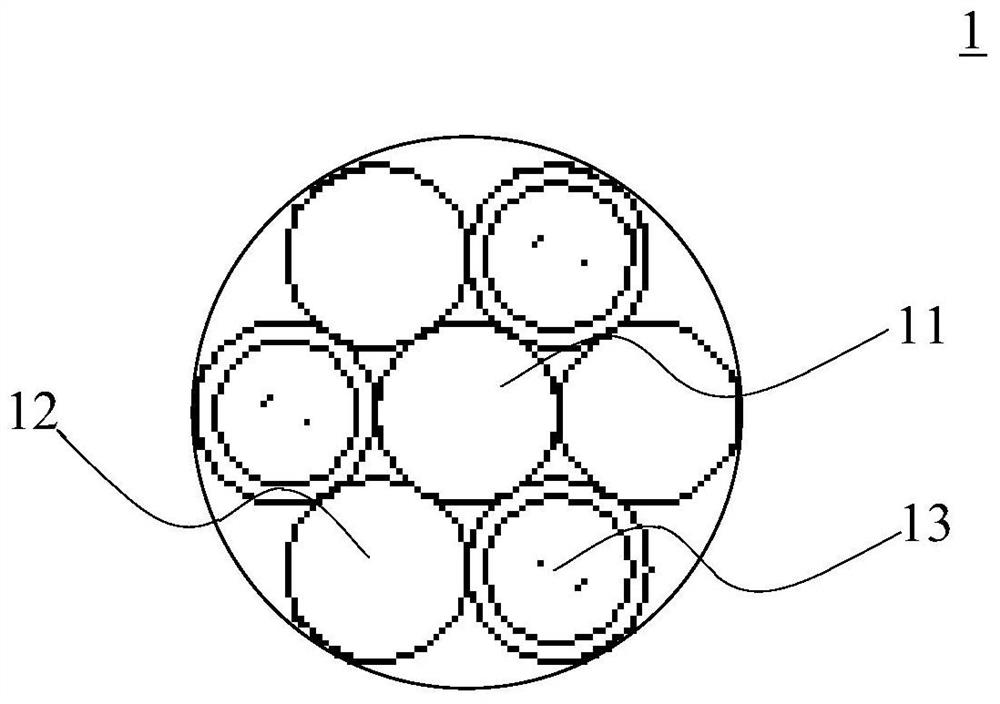

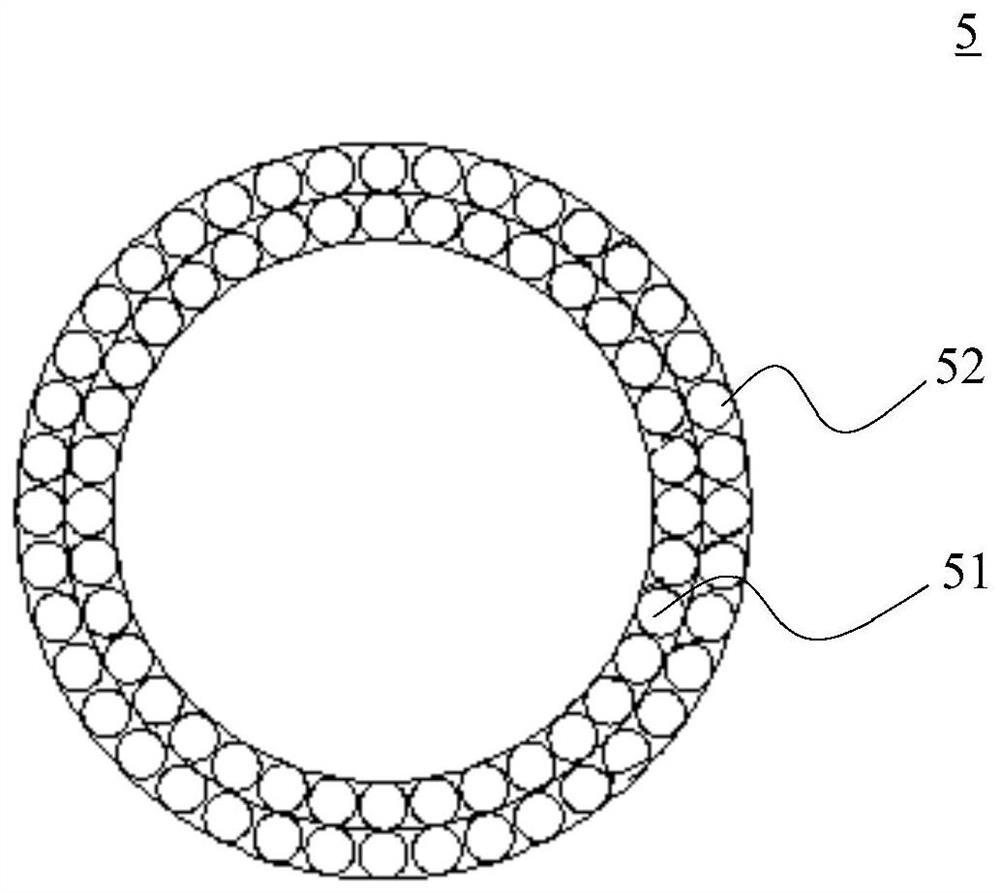

[0052] Usually, when the sea area where the mooring line is located is shallow, the mooring line is subject to a large bending load, and a metal armor layer is usually used to improve the bending resistance of the mooring line; when the sea area where the mooring line is located is deep When the mooring line is deep, the axial load on the mooring line is relatively large, and the length of the mooring line is large, resulting in a large weight. Usually, a non-metallic armor layer is used to improve the axial stiffness of the mooring line and reduce the weight of the mooring line. However, when affected by complex environmental factors such as typhoons, waves, and water impacts, the above-mentioned mooring lines are subjected to large axial loads and bending loads. The axial bearing stiffness of the mooring cable with only metal armor layer is insufficient, and the axial deformation of the cable core is relatively large when subjected to a large axial load, resulting in the fail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com