Anti-corrosion painting material treatment method for pipeline external surface

A technology of spraying materials and anti-corrosion treatment, which is applied in the direction of pipeline anti-corrosion/rust protection, pipeline protection, damage protection, etc. Strong anode stripping ability, good anti-corrosion performance, and strong root thorn ability for deep-rooted plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

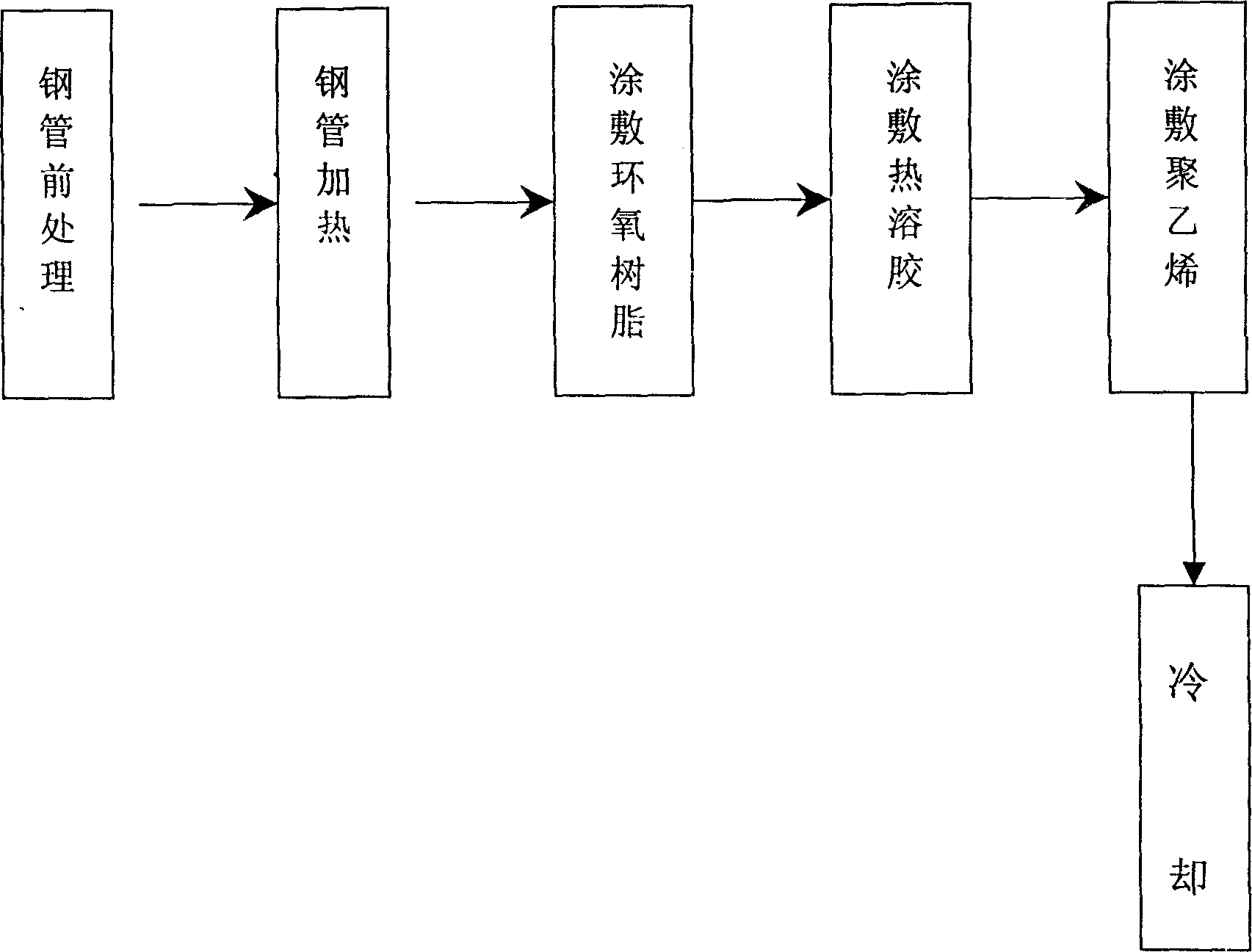

[0037] according to figure 1 Shown technology, the present invention carries out according to the following steps:

[0038] 1. Pre-treatment of steel pipes: sandblasting and trimming the outer surface of steel pipes;

[0039] 2. Steel pipe preheating: the temperature of the preheating furnace is 190°C, and the temperature of the steel pipe reaches 150°C;

[0040] 3. After the steel pipe is preheated, use electrostatic spraying equipment to gradually spray on the outer surface of the steel pipe:

[0041] a. Spray a layer of epoxy resin first: use epoxy resin with a particle size of 100 mesh, control the spraying time per centimeter of pipe within 2 to 3 seconds, and the thickness of epoxy resin after spraying is 0.08mm;

[0042] b. Then spray a layer of hot melt adhesive: use hot melt adhesive with a melting point of 110-120°C, and the thickness of the hot melt adhesive is 0.1mm;

[0043] c. Then spray polyethylene, the thickness of polyethylene is 1mm

[0044] 4. After spr...

Embodiment 2

[0047] 1. Pre-treatment of steel pipes: sandblasting and trimming the outer surface of steel pipes;

[0048] 2. Steel pipe preheating: the temperature of the preheating furnace is 180°C, and the temperature of the steel pipe reaches 160°C;

[0049] 3. After the steel pipe is preheated, spray on the outer surface of the steel pipe step by step

[0050] a. Spray a layer of epoxy resin first, use epoxy resin with a particle size of 130 mesh, control the spraying time per centimeter of pipe within 2 to 3 seconds, and the thickness of epoxy resin at 0.09mm

[0051] b. Continuously spray a layer of hot melt adhesive, use hot melt adhesive with a melting point of 110-120°C, and the thickness of the hot melt adhesive is 0.2mm

[0052] c. Then spray polyethylene, the thickness of polyethylene is 1.5mm

[0053] 4. After spraying three layers of materials, the steel pipe needs to be solidified and leveled at 210°C for 35min. 5. The steel pipe is taken out of the furnace and cooled to c...

Embodiment 3

[0055] 1. Pre-treatment of steel pipes: sandblasting and trimming the outer surface of steel pipes;

[0056] 2. Steel pipe preheating: the temperature of the preheating furnace is 210°C, and the temperature of the steel pipe reaches 170°C;

[0057] 3. After the steel pipe is preheated, spray on the outer surface of the steel pipe step by step

[0058] a. Spray a layer of epoxy resin first, use epoxy resin with a particle size of 100 mesh, control the spraying time per centimeter of pipe within 2-3 seconds, and the thickness of epoxy resin is 0.085mm;

[0059] b. Then spray a layer of hot melt adhesive, using hot melt adhesive with a melting point of 110-120°C, and the thickness of the hot melt adhesive is 0.15mm;

[0060] c. Then spray polyethylene, the thickness of polyethylene is 1mm;

[0061] 4. After spraying the three-layer material, the steel pipe needs to be cured and leveled at a temperature of 210°C for 30min.

[0062] 5. The steel pipe is taken out of the furnace,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com