Alumina ceramic powder, alumina ceramic and preparation method of alumina ceramic

A technology of alumina ceramic powder and alumina ceramics, applied in the field of ceramics, can solve the problems of affecting the service life of resistors and being susceptible to force fracture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

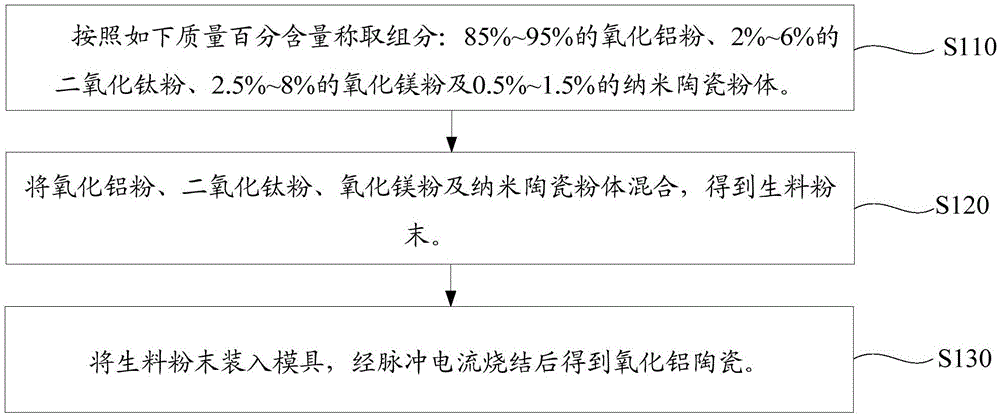

[0028] Such as figure 1 Shown, the preparation method of the alumina ceramics of an embodiment, comprises the steps:

[0029] Step S110: Weigh the components according to the following mass percentages: 85% to 95% of alumina powder, 2% to 6% of titanium dioxide powder, 2.5% to 8% of magnesium oxide powder and 0.5% to 1.5% of nano Ceramic powder.

[0030] Further, the components are weighed according to the following mass percentages: 91% to 95% of alumina powder, 2% to 3.5% of titanium dioxide powder, 2.5% to 5% of magnesium oxide powder and 0.5% to 1.0% of nano Ceramic powder.

[0031] Wherein, the nano-ceramic powder is chromium oxide powder or silicon nitride powder.

[0032] Titanium dioxide powder and magnesium oxide powder are used to dope and modify alumina powder. Titanium dioxide and magnesium oxide can be distributed in the grain boundary of alumina ceramics in the form of glass phase, thus greatly enhancing the slidability between alumina grains. , so that the m...

Embodiment 1

[0046] The preparation process of the alumina ceramics of the present embodiment is as follows:

[0047] (1) Take the components according to the following mass percentages: 95% alumina powder, 2% titanium dioxide powder, 2.5% magnesium oxide powder and 0.5% nano-chromium oxide powder, wherein alumina powder, titanium dioxide powder , The particle size of the magnesium oxide powder is 0.5-1 micron, and the particle size of the nano-chromium oxide powder is 10-25 nanometers.

[0048](2) Put alumina powder, titanium dioxide powder, magnesium oxide powder and nano-chromium oxide powder into a ball mill, add ethanol, and use zirconia balls as the ball milling medium. Then ball milling and mixing at a rate of 300 rpm for 30 hours to obtain a slurry, which was dried naturally for 10 hours, and then dried in an oven at 50° C. for 12 hours to obtain a raw meal powder with a mass moisture content of 1% or less.

[0049] (3) Pass the raw meal powder obtained in step (2) through a 100-m...

Embodiment 2

[0052] The preparation process of the alumina ceramics of the present embodiment is as follows:

[0053] (1) Weigh the components according to the following mass percentages: 91% alumina powder, 3.5% titanium dioxide powder, 5% magnesium oxide powder and 0.5% nano-silicon nitride powder, wherein alumina powder, titanium dioxide powder The particle diameters of magnesium oxide powder and magnesium oxide powder are both 1-2 microns, and the particle diameters of nano-silicon nitride powder are 30-40 nanometers.

[0054] (2) Put alumina powder, titanium dioxide powder, magnesium oxide powder and nano-silicon nitride powder into a ball mill, add water as a solvent, and zirconia balls as a ball milling medium. Then ball milling and mixing at a rate of 300 rpm for 30 hours to obtain a slurry. The slurry was naturally dried for 10 hours, and then dried in an oven at 50° C. for 12 hours to obtain raw meal powder.

[0055] (3) Pass the raw meal powder obtained in step (2) through a 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com