Tunnel lining rapid repair structure based on carbon fiber woven mesh and repair method thereof

A carbon fiber weaving and repairing structure technology is applied in the field of tunnel engineering disease prevention and control, which can solve problems such as the inability to adapt to the development of tunnel engineering maintenance and repair, and the inability of tunnel lining to produce mechanical reinforcement effects, so as to improve integrity and stability, and improve its own strength. And the effect of self-stabilizing ability and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

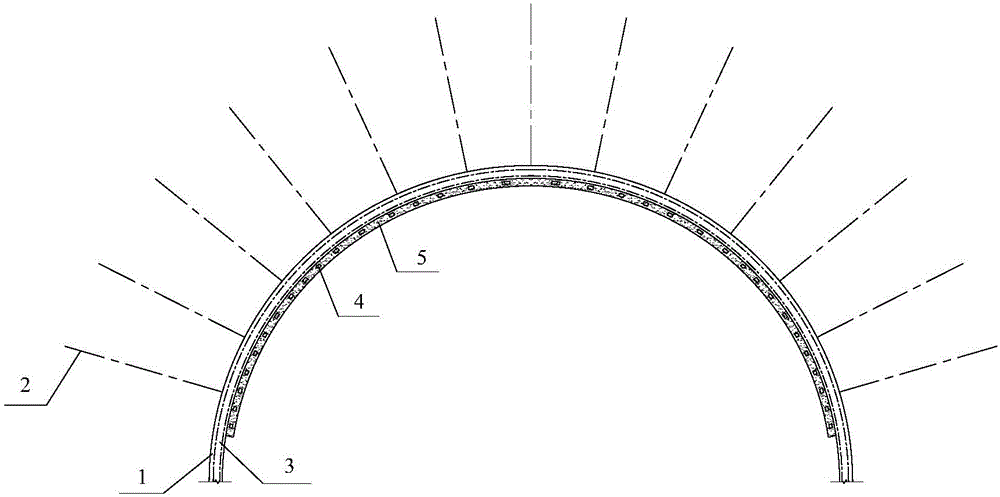

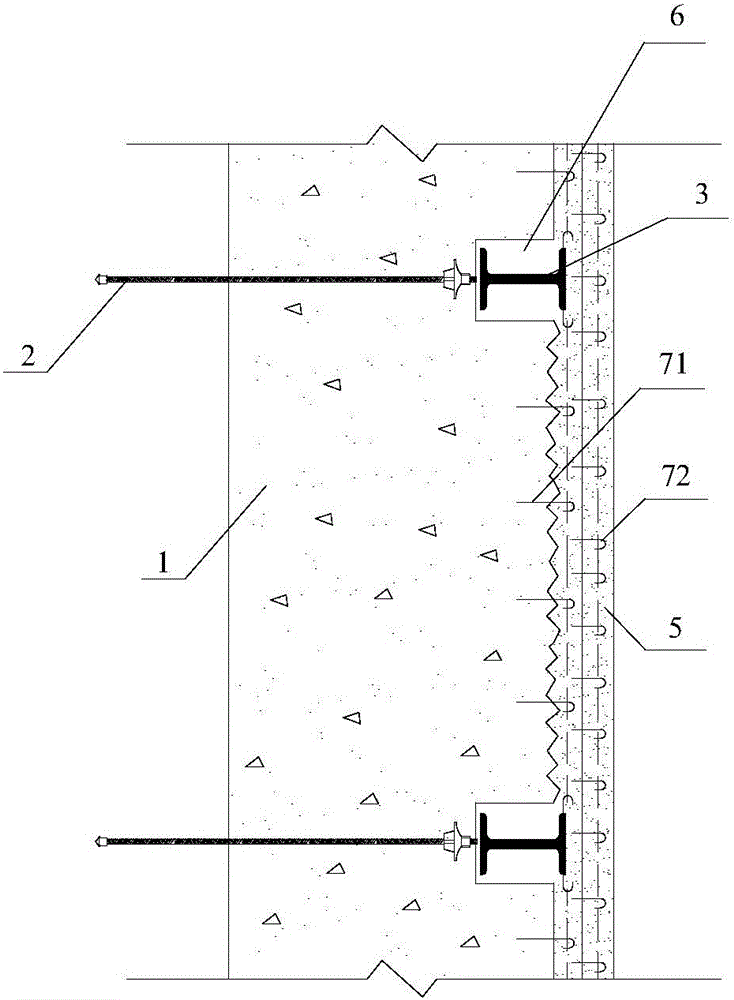

[0053] see figure 1 , figure 2 , image 3 , Figure 4 , a tunnel lining rapid repair structure based on carbon fiber woven mesh mainly consists of tunnel lining 1, self-advancing hollow grouting anchor rod 2, I-beam 3, carbon fiber woven mesh 4, composite mortar 5, groove 6 and U-shaped hook and so on.

[0054] The grooves 6 are arranged on the tunnel lining 1, and the width is preferably 10cm, the depth is preferably 20cm, and the distance along the tunnel axis is preferably 1.5m-2.0m.

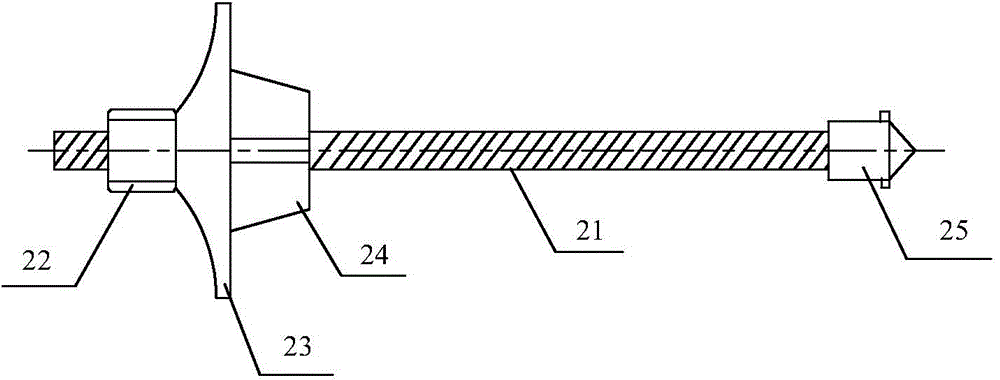

[0055] The self-advancing hollow grouting anchor 2 is arranged in the groove 6, and its circumferential distance should be 0.5m. Composition, the outer diameter of the hollow fully threaded anchor body 21 should be Φ28mm, the tensile strength ≧650MPa, the length should be 3.5m, the grouting slurry should be cement water glass double slurry, and the volume ratio of the two should be 1:0.6~ 1:1.

[0056] I-beam 3 is arranged in groove 6, and its type should be I18, and its section height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com