Preparation technology for glass ceramics sheet

A technology of glass-ceramic and preparation process, which is applied in glass manufacturing equipment, glass molding, glass rolling, etc., can solve problems that do not specifically involve technical details, etc., and achieve improved bending resistance, less deformation, and quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a glass-ceramic thin plate, which includes the following components and contents in terms of weight percentage: SiO 2 60.3%; Al 2 o 3 5.5%;K 2 O3.3%; Na 2 O9.6%; F5.0%; CaO15.6%; MgO0.1%; clarifying agent - arsenic trioxide (As 2 o 3 )0.6%.

[0036] In this example, according to the above-mentioned components and contents, a glass-ceramic thin plate was prepared and a product of the glass-ceramic thin plate was produced. The preparation process is as follows:

[0037] Step 1, by weight percentage, weigh SiO 2 60.3%, A1 2 o 3 5.5%, K 2 O3.3%, Na 2 O9.6%, F5.0%, CaO15.6%, MgO0.1%, clarifying agent - arsenic trioxide 0.6%, mix uniformly to obtain batch materials;

[0038] Step 2: Put the batch material into the melting furnace at a melting temperature of 1510°C. After the batch material is melted, it enters the clarification chamber through the liquid flow hole, the ascending channel, and the forehearth. Under the condition of stirring, ...

Embodiment 2

[0043] This embodiment provides a glass-ceramic thin plate, which includes the following components and contents in terms of weight percentage: SiO 2 63.3%; Al 2 o 3 4.5%;K 2 O0.3%; Na 2 O10.1%; F5.5%; CaO15.6%; MgO0.1; clarifying agent - arsenic trioxide 0.6%.

[0044] In this example, according to the above-mentioned components and contents, a glass-ceramic thin plate was prepared and a product of the glass-ceramic thin plate was produced. The preparation process is as follows:

[0045] Step 1, by weight percentage, weigh SiO 2 58.2%, A1 2 o 3 6.0%, K 2 O3.9%, Na 2 O9.8%, F5.5%, CaO15.9%, MgO0.1%, clarifying agent - arsenic trioxide (As 2 o 3 )0.6%, mixed uniformly to obtain the batch;

[0046] Step 2: Put the batch material into the melting furnace and melt it at the melting temperature of 1510°C. After the batch material is melted, it enters the clarification chamber through the liquid flow hole, the ascending channel, and the material channel. Under the condit...

Embodiment 3

[0051] This embodiment provides a glass-ceramic thin plate, which includes the following components and contents in terms of weight percentage: SiO 2 58.9%; Al 2 o 3 6.3%;K 2 O4.3%; Na 2 O9.8%; F4.5%; CaO15.5%; MgO0.1%; clarifying agent - arsenic trioxide 0.6%.

[0052] In this example, according to the above-mentioned components and contents, a glass-ceramic thin plate was prepared and a product of the glass-ceramic thin plate was produced. The preparation process is as follows:

[0053] Step 1, by weight percentage, weigh the SiO-containing 2 59.7%, A1 2 o 3 6.3%, K 2 O4.3%, Na 2 O9.8%, F4.5%, CaO14.7%, MgO0.1%, clarifying agent (As 2 o 3 )0.6%, mixed uniformly to obtain the batch;

[0054] Step 2. Put the batch material into the melting furnace and melt it at a melting temperature of 1515°C. After the batch material is melted, it enters the clarification chamber through the liquid flow hole, the ascending channel, and the material channel. Carry out clarificatio...

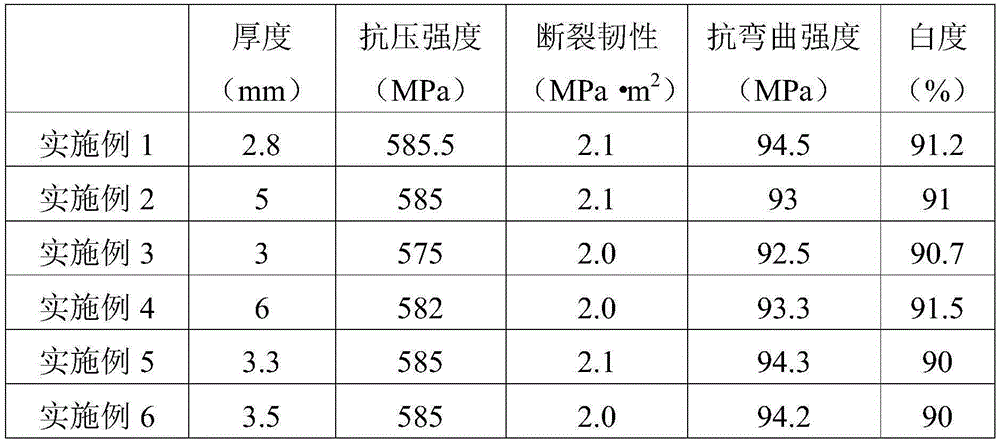

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com