Chambering method of chambering equipment on construction site

A technology for construction sites and equipment, used in drilling equipment, earth-moving drilling, drilling without stripping topsoil, etc. The effect of high longitudinal depth and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

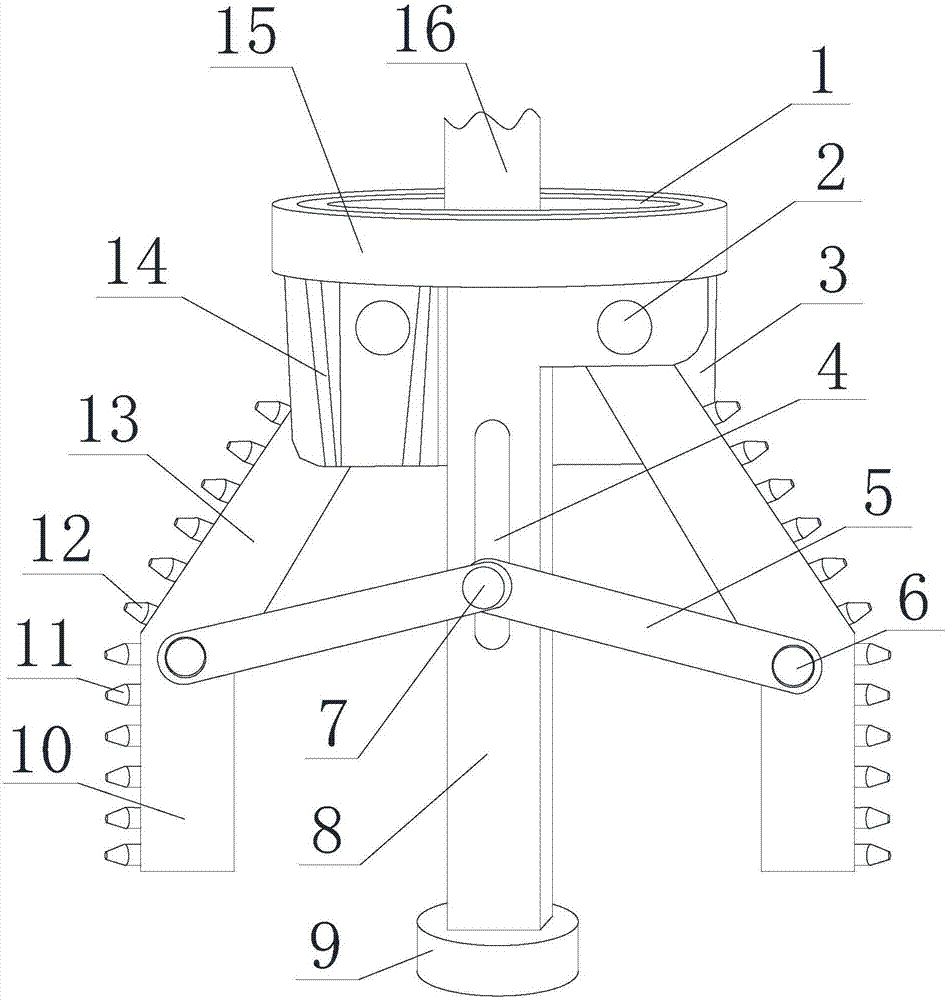

[0026]Such as Figure 1 to Figure 3 As shown, a hole reaming method for hole reaming equipment on a construction site includes a connection seat 15, a connection hole 1 is arranged in the connection seat 15, and the connection hole 1 is a threaded hole, which is used to connect the connection seat 15 to other equipment , the connection hole 1 is not a through hole, so that the top of the support column 8 can be fixed to the connection seat 15, and two mounting plates 3 arranged parallel to each other are arranged below the connection seat 15, and the top ends of the mounting plates 3 are connected to the connection seat 15. The bottom end of the bottom is fixed vertically, and the support column 8 passes through the area between the mounting plates 3 and is fixed with two mounting plates 3 as an integral structure at the same time. The scraping mechanism includes an inclined plate 13 and a vertical plate 10 connected as an integral structure. The plate 10 is parallel to the su...

Embodiment 2

[0029] Such as Figure 1 to Figure 3 As shown, on the basis of the above embodiment, the top of the support column 8 is concaved to form a cavity, the bottom surface of the connecting hole 1 is concaved to form a through hole, and the through hole communicates with the cavity, and a connecting rod 16 is arranged in the cavity. And the top end of the connecting rod 16 passes through the through hole and the connecting hole 1 of the connecting seat 15 , and the connecting rod 16 can move along the axial direction of the support column 8 in the cavity and the connecting hole 1 . In order to keep moving smoothly, it is better to design the axis of the support column, the axis of the connecting rod 16, the axis of the connecting hole 1, the axis of the through hole and the axis of the cavity to coincide.

[0030] Two through grooves 4 are arranged on the side wall of the support column 8, and the through groove 4 is arranged symmetrically on the side wall of the support column 8 an...

Embodiment 3

[0032] Such as Figure 1 to Figure 3 As shown, on the basis of the above embodiment, a connecting arm 5 is arranged between the scraping mechanism and the support column 8, the number of the scraping mechanism is two groups, and the connecting arms 5 connected to each group of scraping mechanism are two pieces, and the scraping mechanism And the support column 8 is arranged between the two connecting arms 5 connected with it, the connecting arm 5 is provided with a pin 6, and the pin 6 on the same group of scraping mechanisms passes through the two connecting arms 5 and the inclined plate 13 at the same time and the connection between the vertical plate 10, and the connecting arm 5 can rotate around the pin one 6, the other end of the connecting arm 5 is connected with the same pin two 7, and the connecting arm 5 can rotate around the pin two 7 turn. When the connecting rod 16 moves, it can drive the scraping mechanism to rotate in the corresponding direction, that is, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com