Coal mine underground spiral hydraulic mechanical reaming device

A hydraulic and screw-type technology, applied in safety devices, drilling equipment, mining equipment, etc., can solve the problems of uneven distribution of hydraulic power, poor expansion effect of the knife arm, unreasonable structure of the knife arm, etc. Efficiency and reaming efficiency, improving the effect of gas drainage, and shortening the construction period of reaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

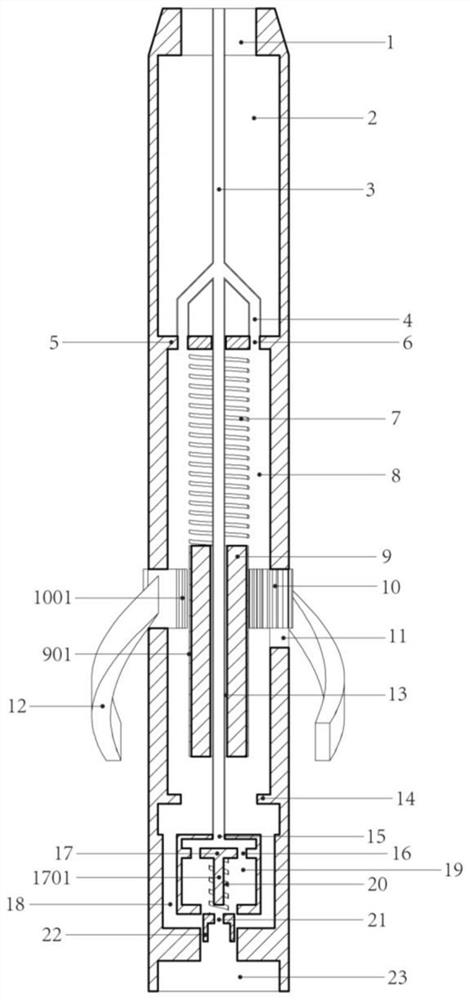

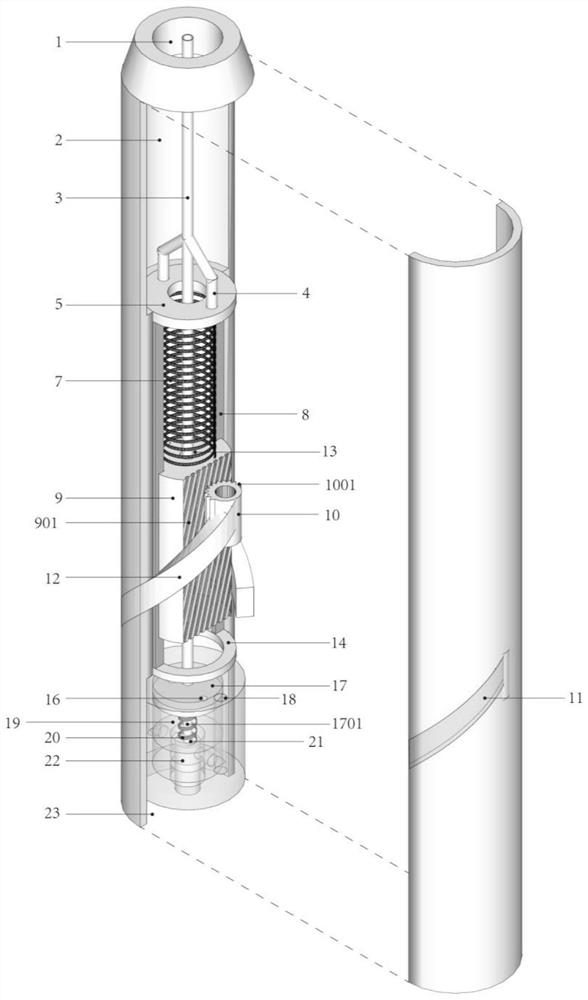

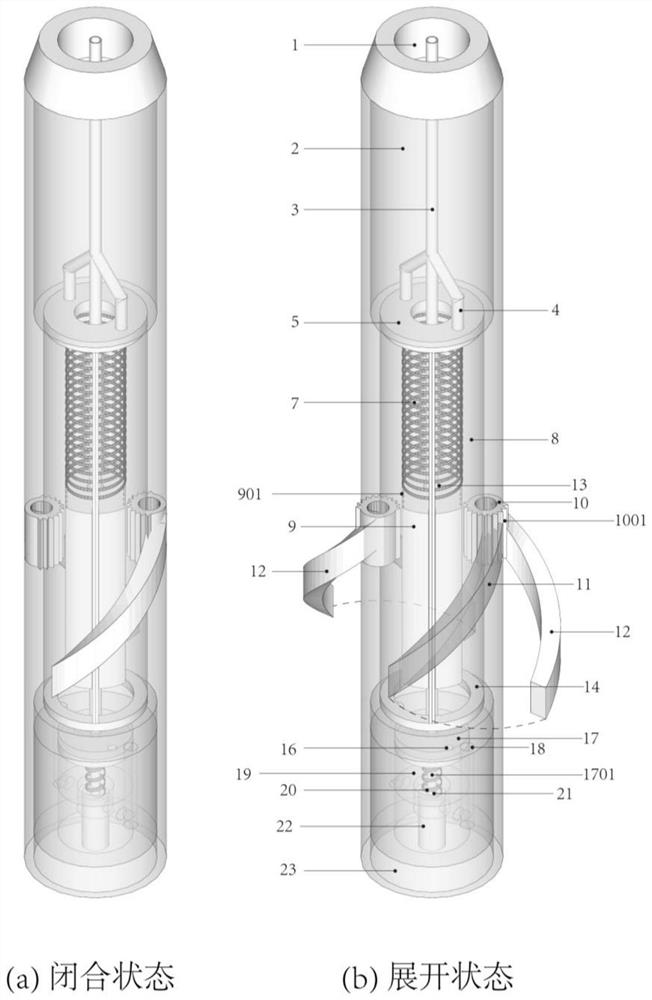

[0014] Attached below figure 1 and image 3 The implementation of the patent of the present invention is further analyzed and described:

[0015] A coal mine underground spiral hydraulic mechanical reaming device, comprising three space cavities: a drill bit cavity 2, a knife arm cavity 8 and a water valve cavity 19, a power drive device is built in the knife arm cavity 8, and the water valve cavity 19 has a built-in high and low pressure cooling water switching device and a spiral knife arm device; the center of the drill cavity 2 is provided with a low pressure water pipeline 3, and the low pressure water pipeline 3 runs through to the low pressure water inlet 15 at the end of the device, and the side branch of the water flow 4 Connect the drill bit cavity 2 and the knife arm cavity 8; a pair of spiral knife arms 12 for reaming are installed on the side of the device body, and the root of the spiral knife arm 12 is a knife arm gear body 10 processed with helical teeth; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com