Method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building

A technology for long drilling and coalbed methane, applied in drilling equipment and methods, earthwork drilling, drill bits, etc., can solve the problems of small hole diameter, low extraction efficiency, and small influence range, and achieve improved permeability and enhanced drainage. The effect of improving mining efficiency and avoiding hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

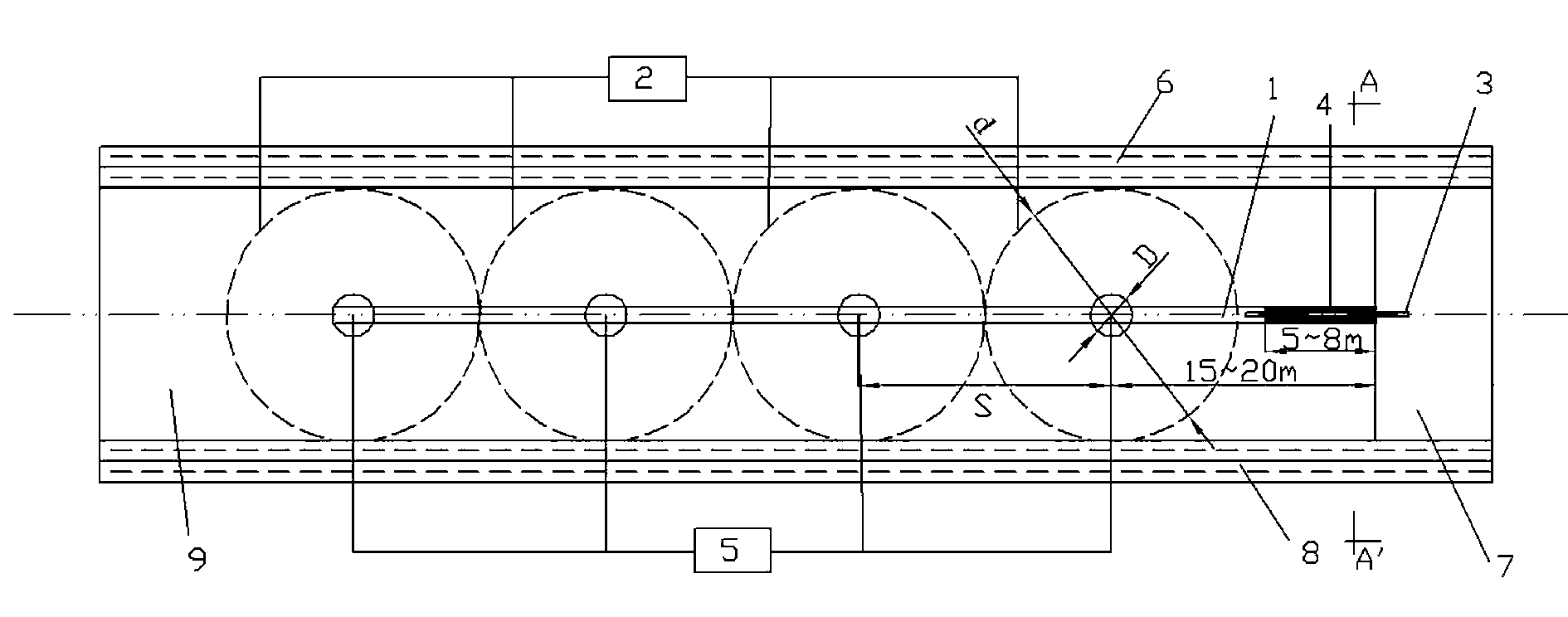

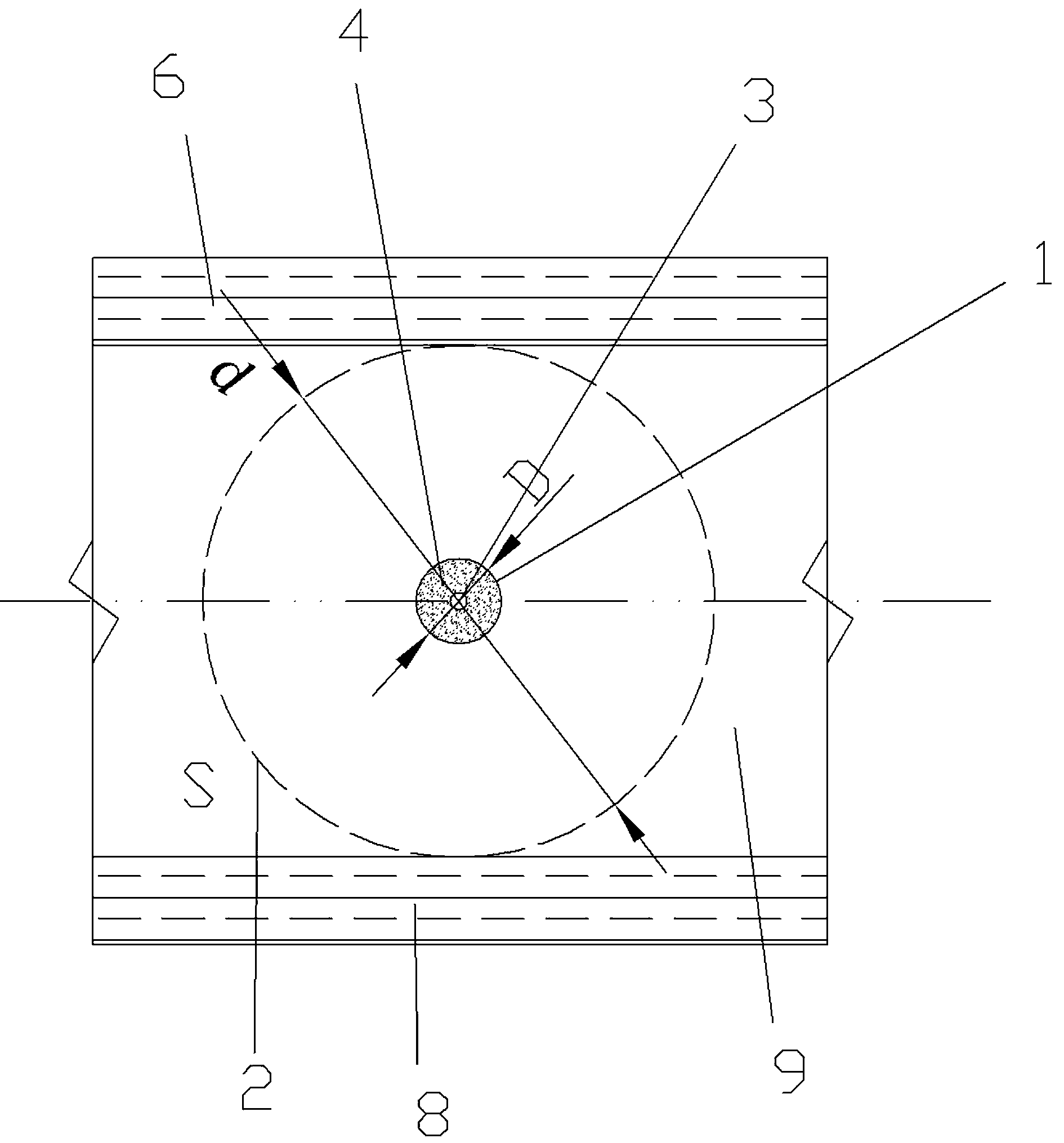

[0029] Embodiment 1: A method for pre-draining coal seam gas by drilling long holes along the bed in the excavation face in series. refer to figure 1 and figure 2 Shown. In a certain area, the thickness of the pre-pumped coal seam M=6000mm in the Shanxi Formation, the length of the pre-pumped roadway is 800m, and the mechanical parameters of coal and rock are unknown. According to the formula , it can be seen that the diameter of the cave is between φ1200mm, and the distance between the caves is given by the formula The estimated distance between the caves is Between 6 and 12m, S=10m is taken now. In the middle of the working face of the pre-excavation coal seam gas drainage roadway (7), use a thousand-meter drilling rig to drill the drainage long borehole (1) in the direction of the pre-excavation roadway, and the diameter of the long borehole is φ96mm. After the drilling reaches the predetermined depth, the hydraulic-mechanical variable-diameter reaming bit while dr...

Embodiment 2

[0030] Example 2: The roadway for gas drainage in the panel area adopts the method of drilling holes parallel to the long coal seam in series to pre-drain coal seam gas, refer to image 3 The situation shown is that the thickness of the pre-pumped coal seam of the Shanxi Formation in a certain area is M=6000mm, the average thickness of the mountain cover in the pre-pumped area is 460m, and the average weight of the rock mass is 25kN / m 3 , the cohesion of the coal seam is 0.4MPa, the internal friction angle of the coal seam is 25°, by the formula

[0031] , the available cave size is about φ1400mm. In addition, the size of the hole is calculated according to the thickness M of the pre-pumped coal seam, according to the formula , it can be seen that the size of the cave is between φ1200mm, comprehensively considered, the diameter of the cave is taken as φ1300mm. Cave spacing is given by the formula , then the hole spacing is Between 6.5m and 13m, the spacing of S=10...

Embodiment 3

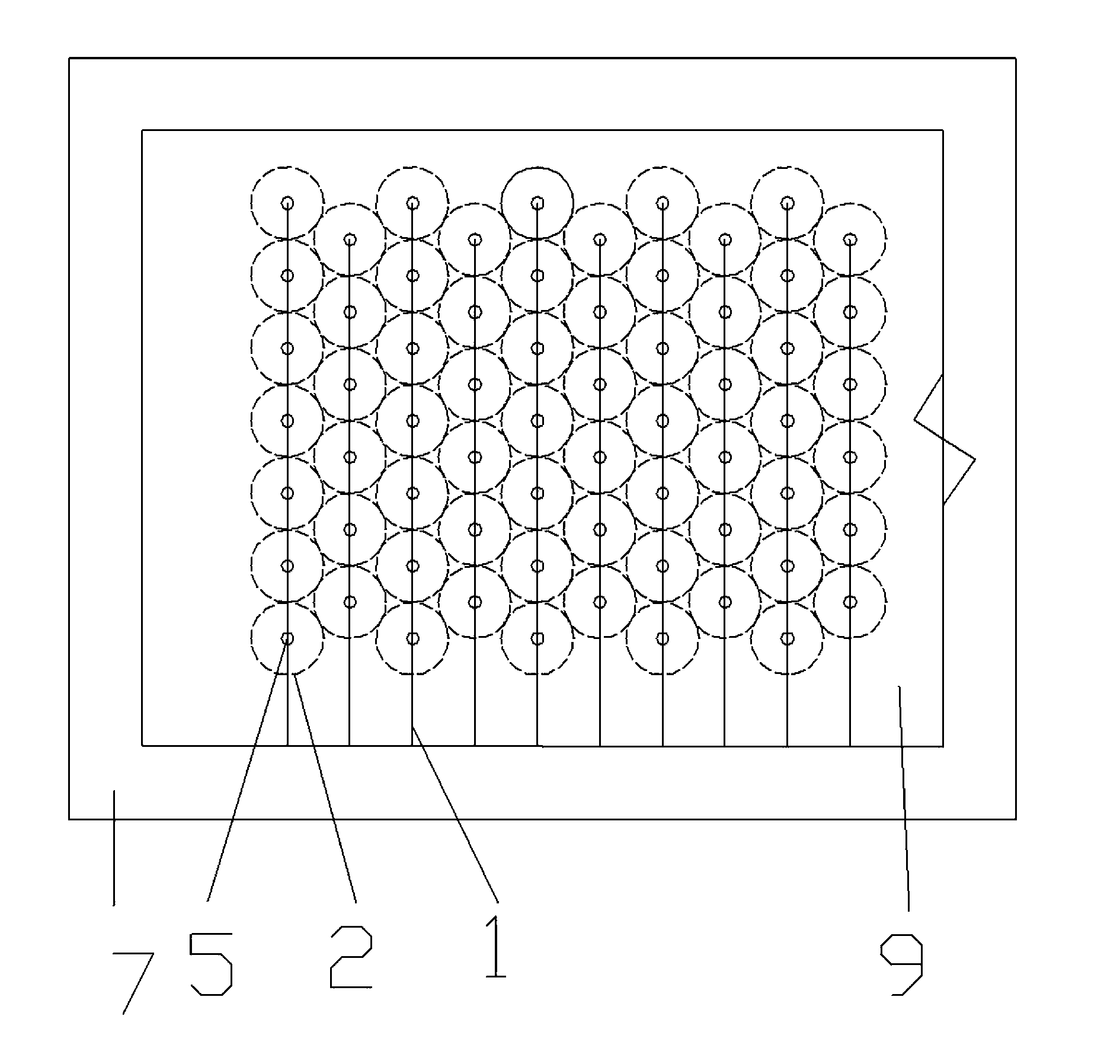

[0032] Example 3: The coal seam gas is pre-drained by making caving holes in series in the mining face through radioactive drilling along the coal seam. refer to Figure 4 , the coal seam gas pre-drainage system is adopted for the coal mining face by drilling holes along the coal seam. According to the thickness M of the coal seam (9) and the maximum influence range of the coal seam cave (2), the size of the gas drainage single hole coal seam cave and the drilling construction are designed. Point position (5) and the angle and spacing of drainage drilling. Then use the drilling rig to drill the drainage borehole (1) in the coal seam gas drainage roadway (7) according to the drilling design trajectory. Caves (5) are built in sequence outside the hole. After the hole is built, a drainage pipe (3) is placed at the orifice, and the gas sealing section (4) of the orifice is sealed, and the borehole drainage pipe (3) is connected to the downhole Drainage system (10) is connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com