Transverse-broaching device

A lateral and appliance technology, applied in drilling equipment, earthmoving, drill bits, etc., can solve the problems of uncontrollable opening angle of airfoil drill pieces, inability to form enlarged holes of different diameters, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

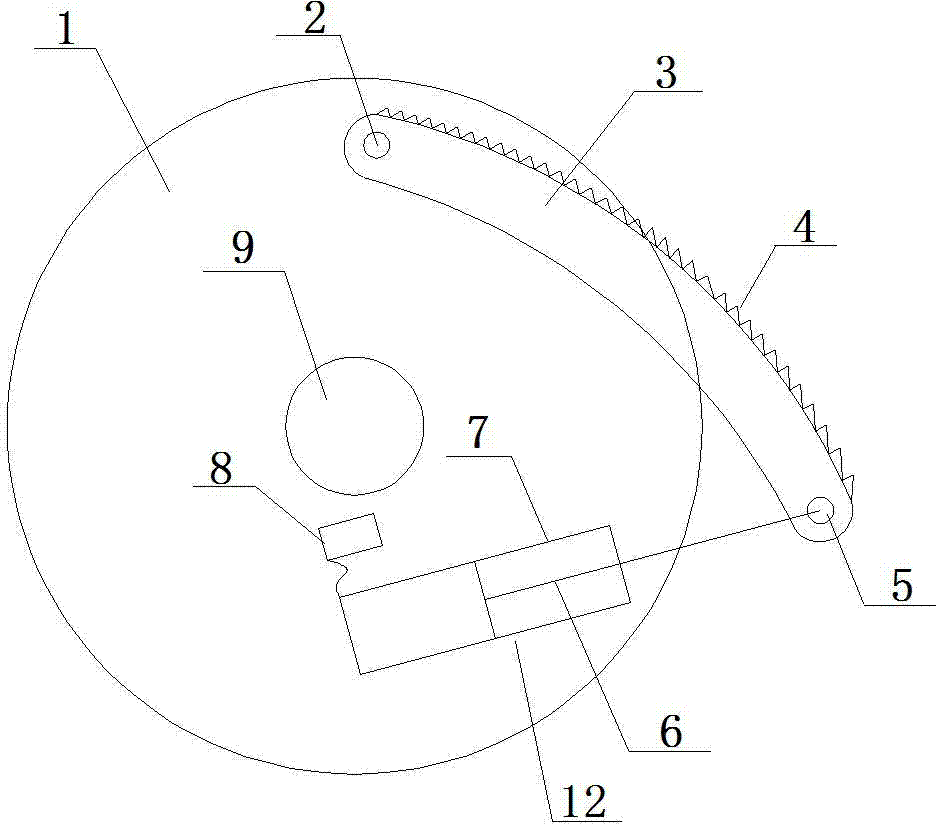

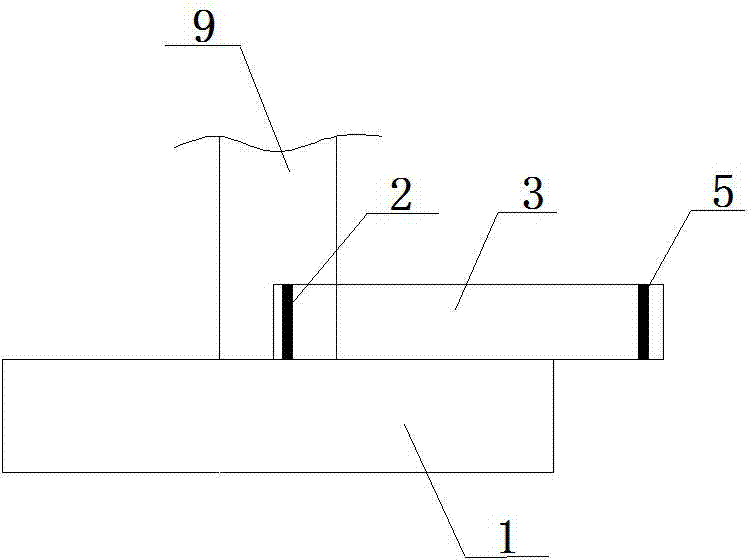

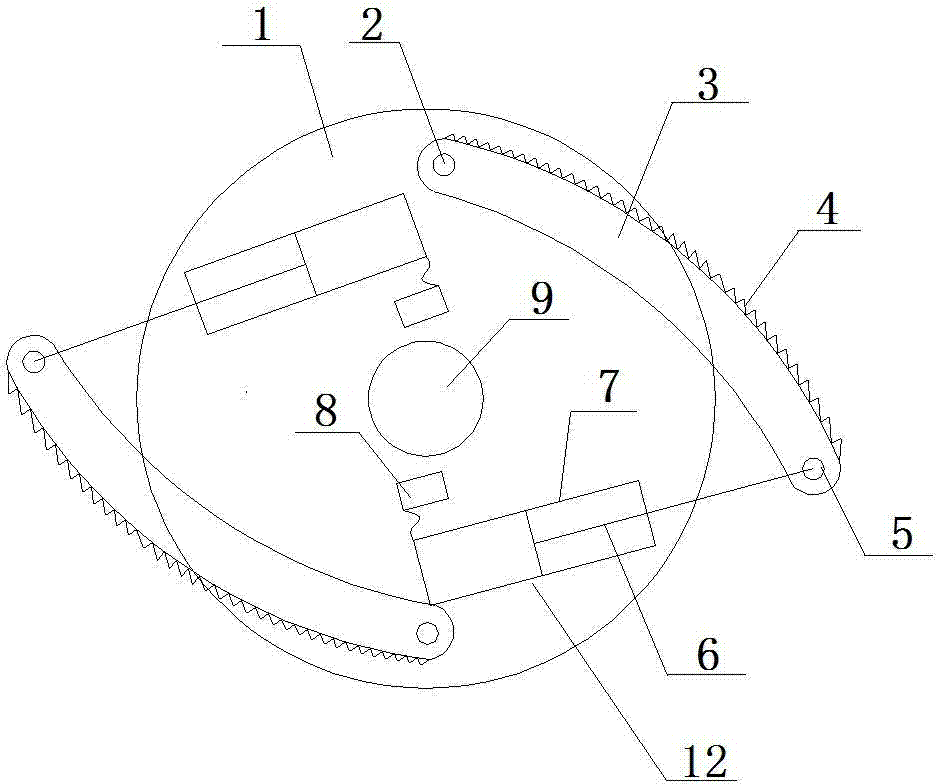

[0019] Embodiment: This embodiment specifically relates to a horizontal widening device, the principle of which is to design a special horizontal drill bit in combination with the power components of the existing rotary drilling rig, so that it can perform the widening operation at the bottom of the hole pile.

[0020] Such as figure 1 , 2 As shown, the horizontal widening device has a rotating shaft 9, the rotating shaft 9 is connected with the existing rotary drilling rig power components above it to obtain the motive force, the bottom of the rotating shaft 9 is a disc-shaped rotating disk 1, and the rotating shaft 9 is used for The rotating disk 1 is driven to rotate, and the outer diameter of the rotating disk 1 is the same as the diameter of the drilled pile; a soil cutting arm 3 is horizontally arranged on the upper surface or the lower surface of the rotating disk 1, and the fixed end of the soil cutting arm 3 passes through the The hinge shaft 2 is hinged and fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com