Drilling device for drilled grouting pile

A technology for drilling cast-in-place piles and drilling devices, which is applied to drill bits, drilling tools, sheet pile walls, etc., can solve problems such as affecting construction quality, complex device structure, and complicated processes, so as to improve drilling efficiency and improve hole reaming. Good efficiency and cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

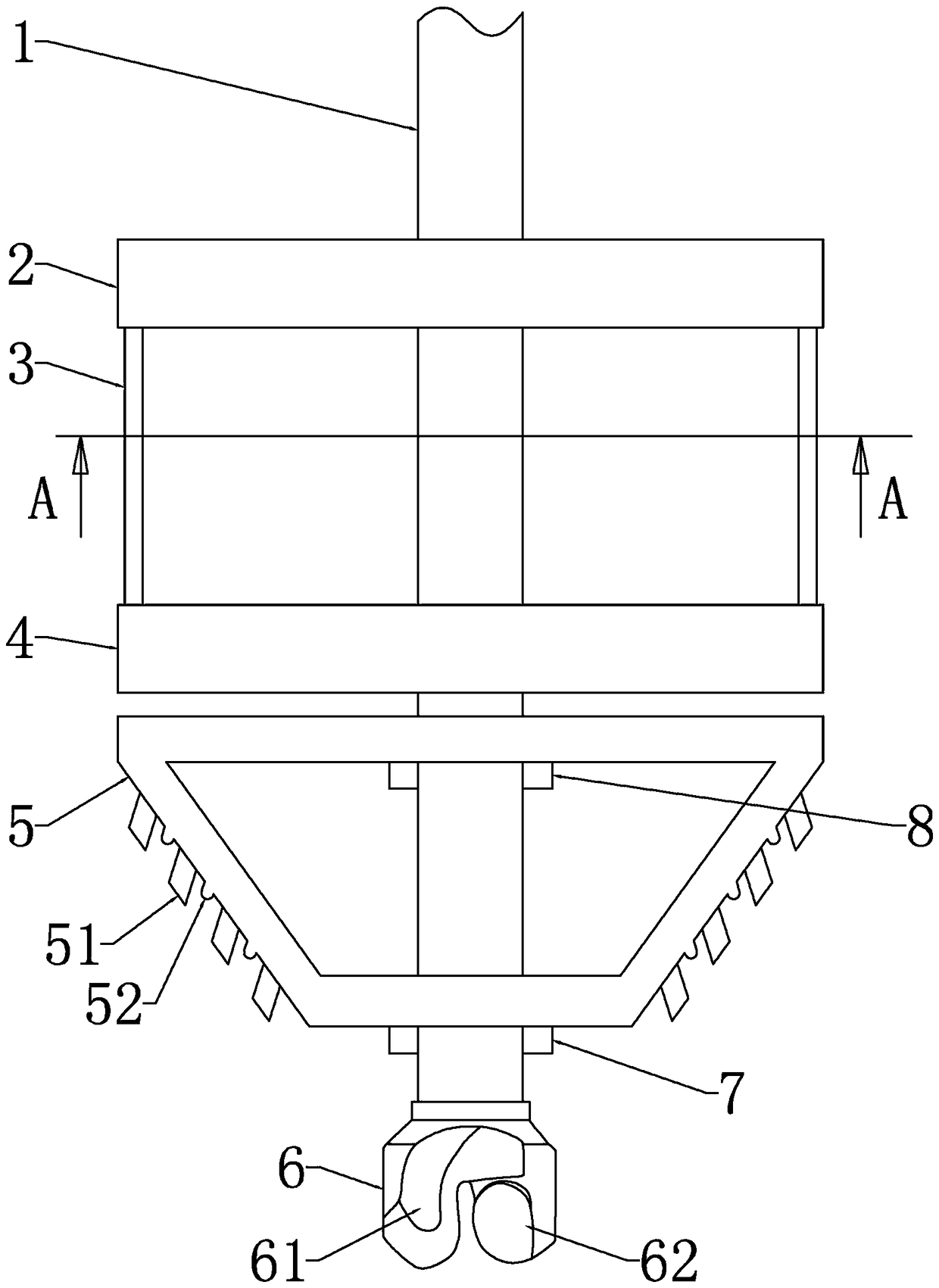

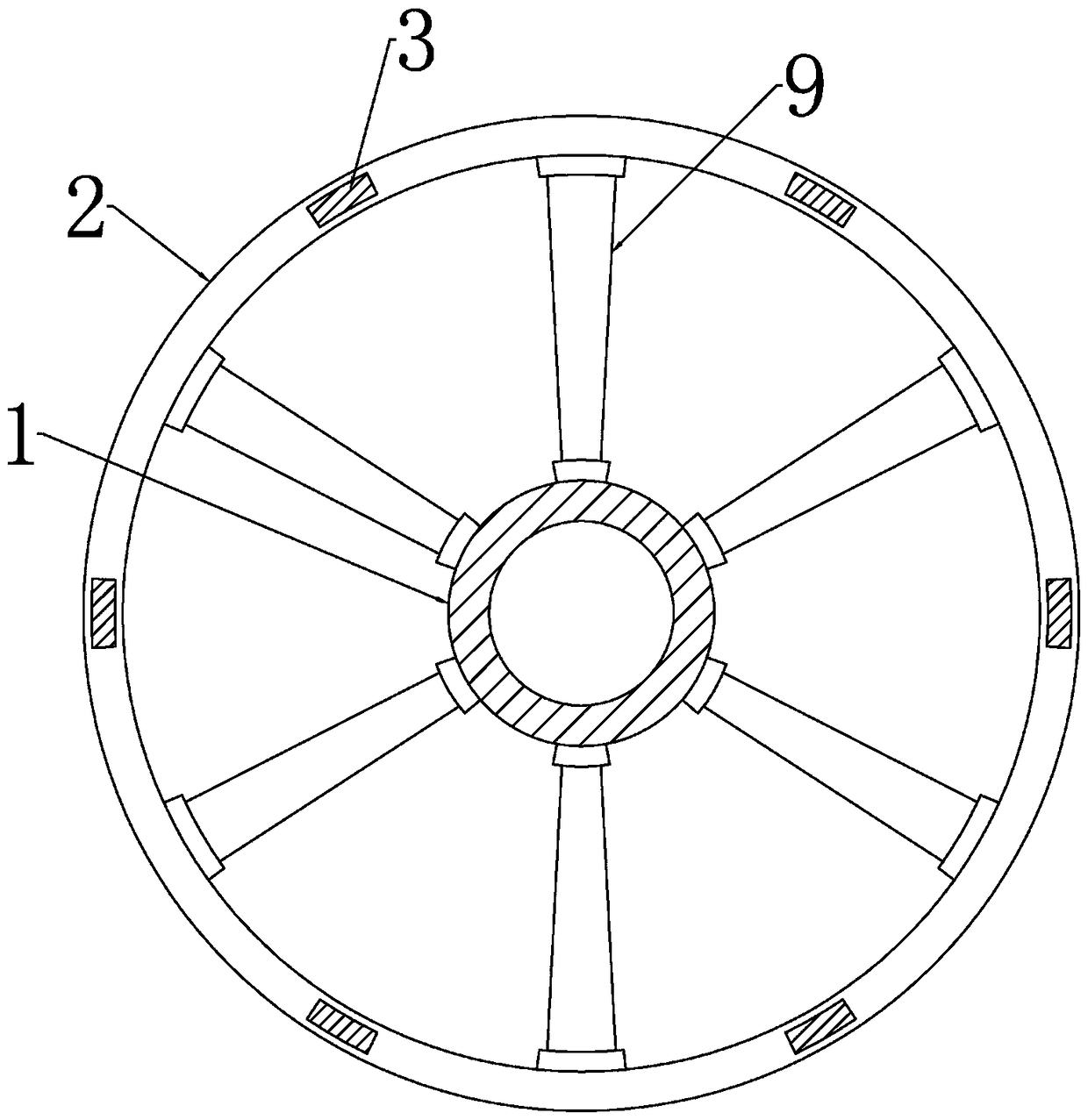

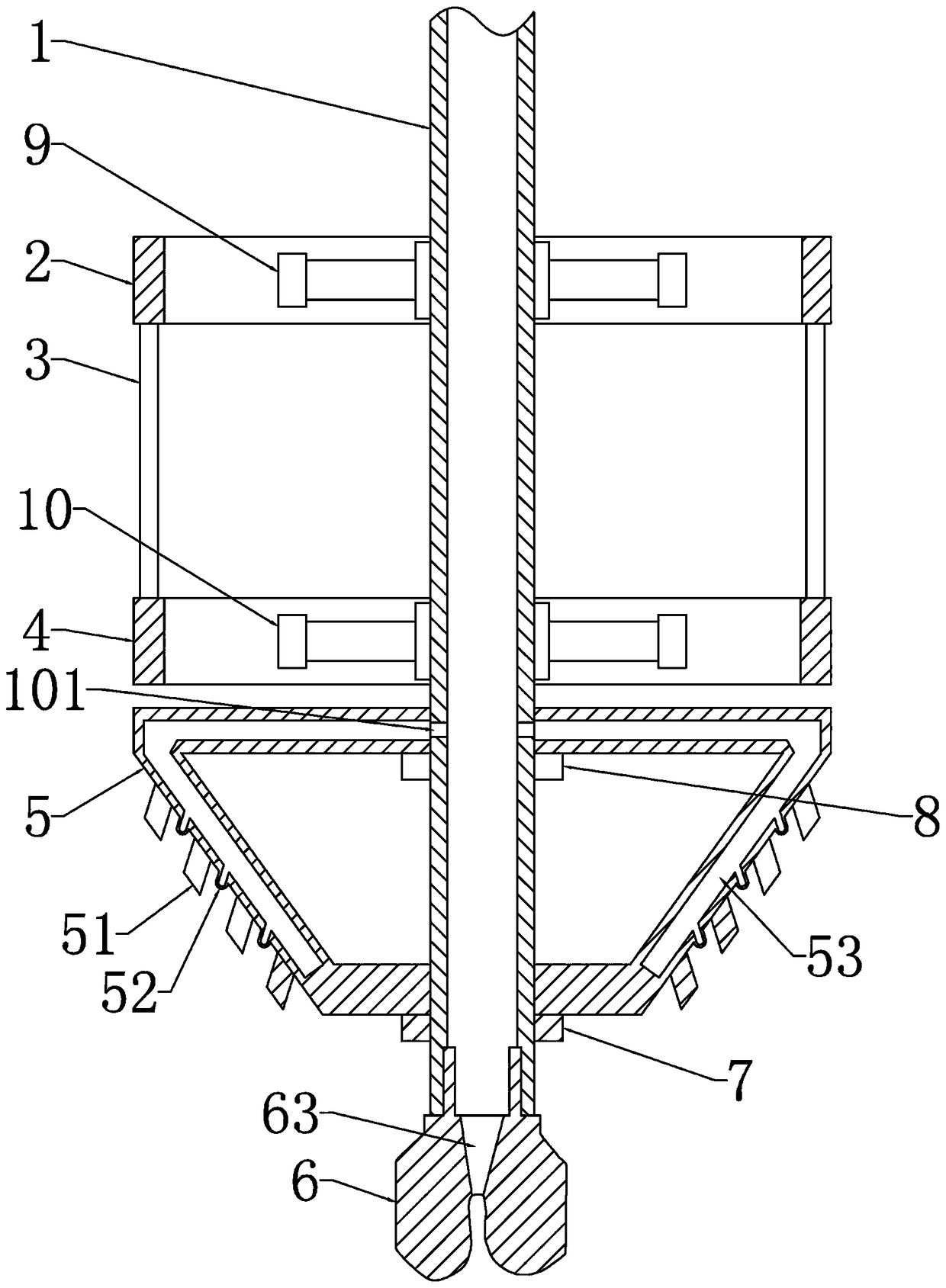

[0019] The specific embodiment of the present invention sees Figure 1-3 , a drilling device for bored piles, including a hollow drill rod 1, a trapezoidal reaming frame 5 and a drill bit 6. The upper end of drill bit 6 is provided with hollow screw rod, and the lower end of hollow drill rod 1 is provided with internal thread, and the external thread of hollow screw rod matches with the internal thread of hollow drill rod 1, and drill bit 6 is screwed on the lower end of hollow drill rod 1. The drill bit 6 includes two helical blade holders 61 in a helically wound shape, the front end faces of the helical blade holders 61 are respectively provided with alloy blades 62, and a drill bit communicating with the inner cavity of the hollow drill rod 1 is arranged between the two helical blade holders 61 Liquid outlet hole 63. The drill bit 6 is threadedly connected with the hollow drill rod 1, which is convenient for disassembly and assembly. The drill bit 6 is provided with two he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com