Novel reamer

A reamer and a new type of technology, applied in the field of reamer, can solve the problems of large reamer reaming resistance, small welding area, rough hole edge, etc., to improve the reaming efficiency and reaming quality, and improve the connection strength. , The effect of reducing the reaming resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

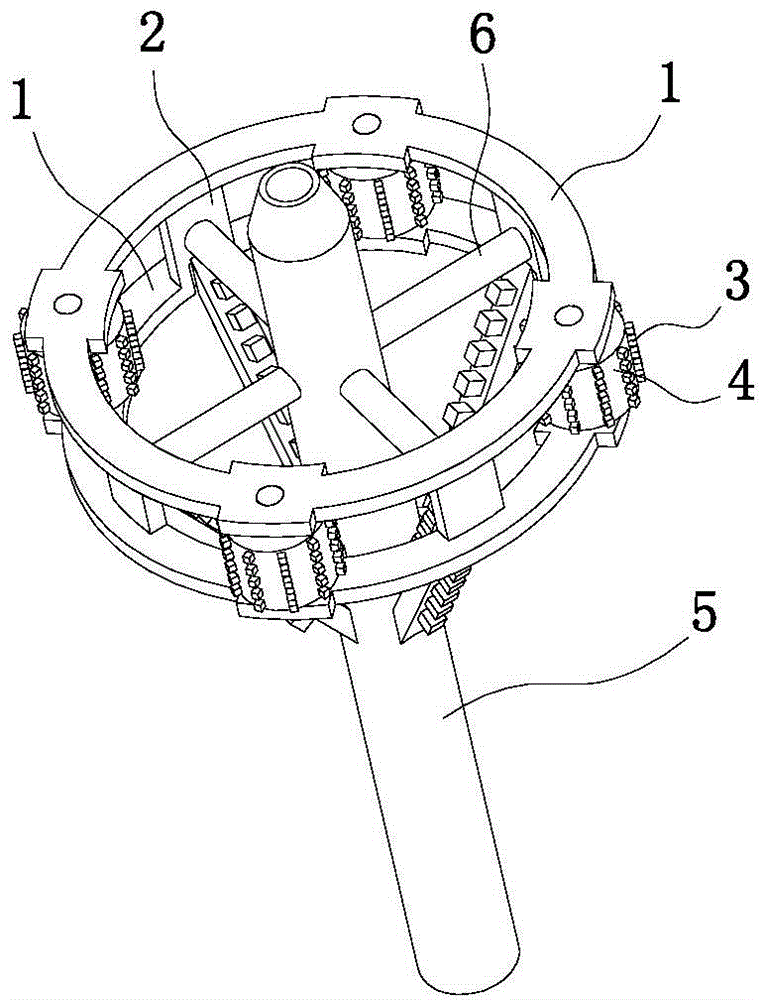

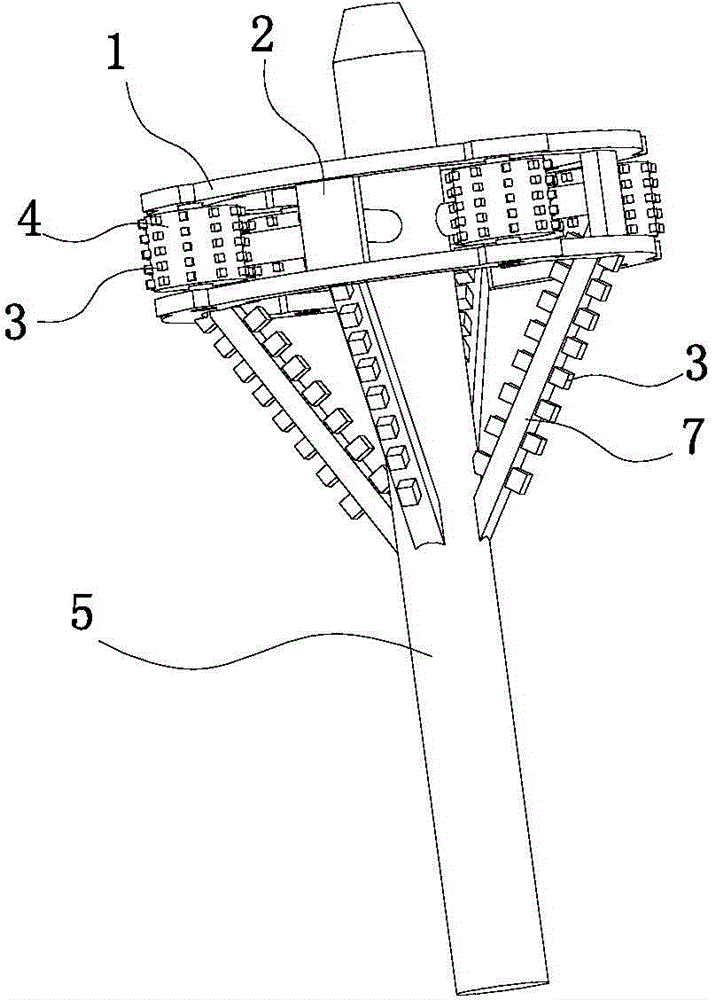

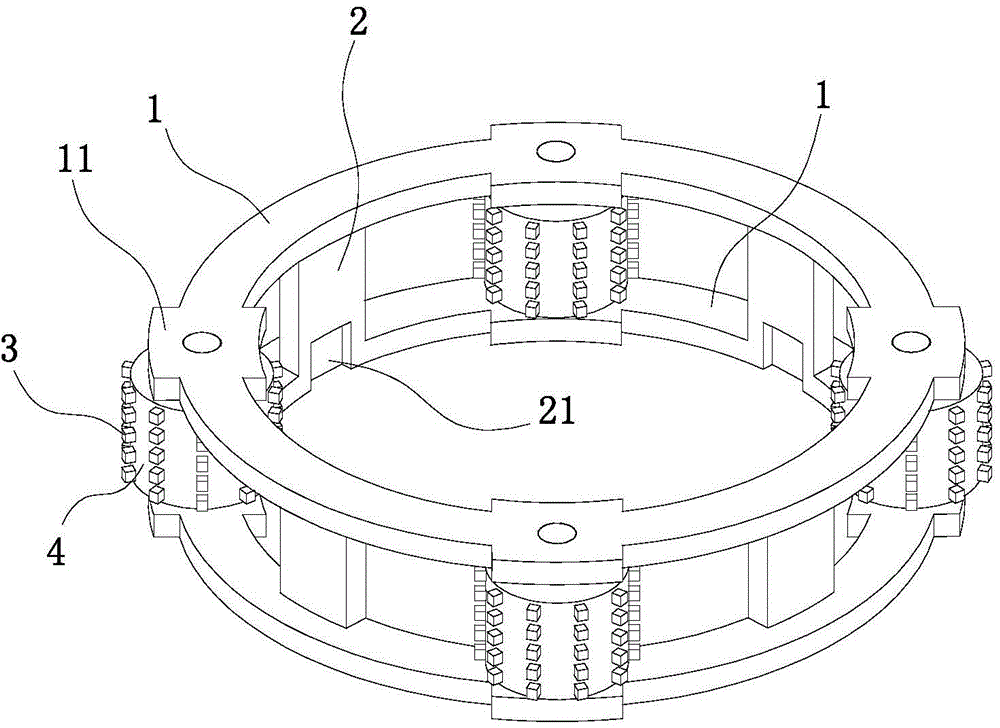

[0016] Such as figure 1 , figure 2 and image 3 As shown, the novel hole reamer of the present embodiment comprises a belt body, the center of the belt body is fixedly connected with the drill rod 5 by means of a cross bar 6, and a plurality of reaming rods 7 are fixedly connected between the belt body and the drill rod 5, and the reamer The rod 7 is arranged symmetrically with respect to the center of the drill rod 5. The drill rod 5, the reaming rod 7 and the cross bar 6 are all hollow structures. The belt body includes belt rings 1 arranged at intervals up and down. There are multiple support plates connected between the two belt rings 1. 2. The inner wall of the lower end of the support plate 2 has a welding groove 21, and the upper end of the reaming rod 7 is welded and fixed in the welding groove 21. The cross section of the reami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com