A kind of hydraulic hole reaming drilling tool and its reaming method for mechanically cavitating coal seam

A technology for hole reaming and hole making, which is applied in drilling equipment and methods, drill bits, earthwork drilling and mining, etc. It can solve problems such as low hole reaming efficiency, reduced extraction efficiency, and heavy workload, so as to improve hole reaming efficiency , shorten the working cycle, reduce the workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing.

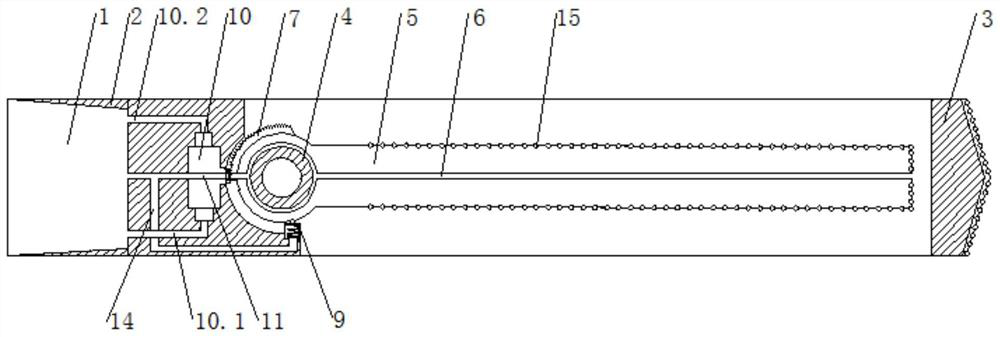

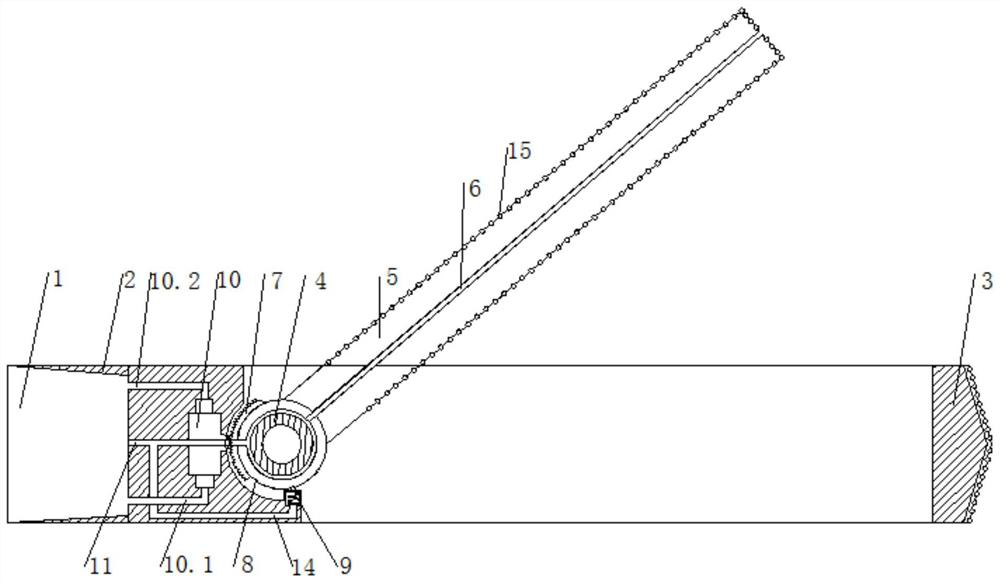

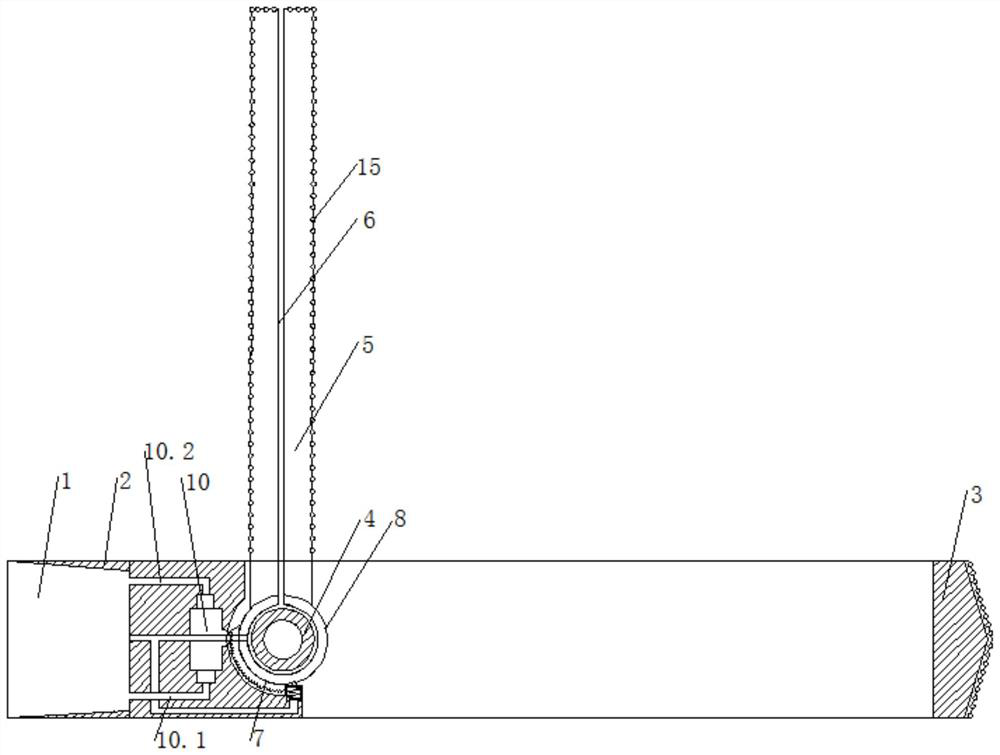

[0051] Such as figure 1 , figure 2 and image 3 As shown, a hydraulic reaming drilling tool for mechanical cavitation coal seam enhancement, including a joint 1, a drilling tool body 2, and a PDC bit 3, the front end of the drilling tool body 2 is equipped with a PDC bit 3, and the rear end of the drilling tool body 2 is connected to Joint 1, drilling tool body 2 is a hollow structure, a hollow cylindrical shaft 4 is installed in the drilling tool body 2 and the hollow cylindrical shaft 4 is perpendicular to the center line of the drilling tool body 2, and the reaming tool 5 is rotatably installed on the hollow cylindrical shaft 4, on the side wall of the pipeline at the front of the drill body 2, there is a through hole for the reamer 5 to be screwed in and out, and an air hole for compressed air and high-pressure water flow to pass through the reamer 5 is provided. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com