A block solid defoamer and preparation method thereof

A solid defoamer, block technology, applied in the field of block solid defoamer and preparation, industrial defoamer, can solve the inconvenience of adjusting the amount of defoamer at any time, unstable liquid defoamer, inconvenient transportation and other issues, to achieve the effect of high cost performance, undemanding conditions, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

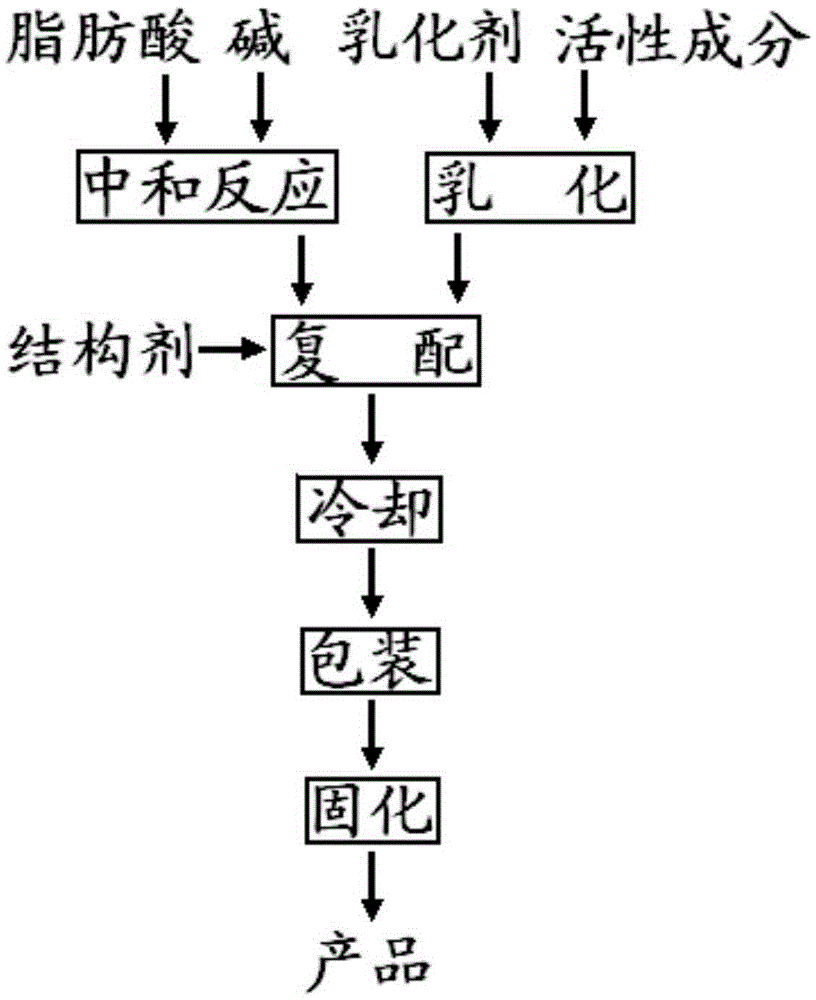

Method used

Image

Examples

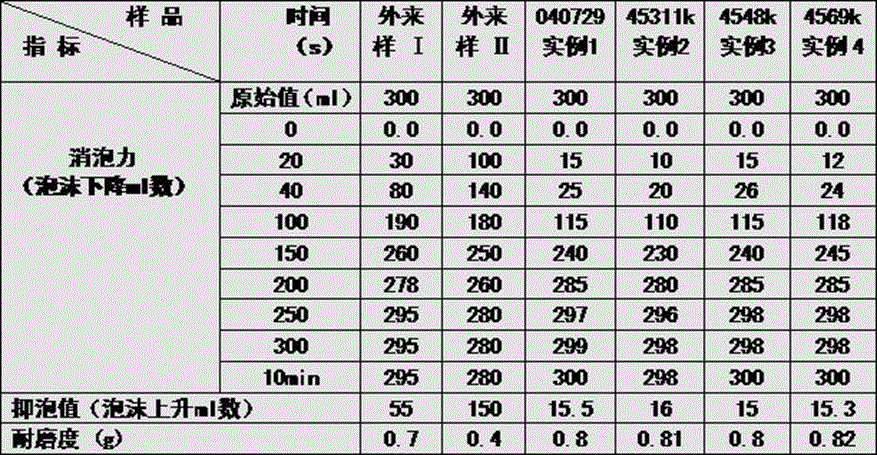

Embodiment 1

[0040] Firstly, 30 parts hardened oil, 20 parts rosin, and 10 parts palm oil are put into the mixed fatty acid of the jacketed and stirred reactor, heated to 80±1℃, and added according to the requirements of the neutralization rate at 95±1% The 30% liquid sodium hydroxide solution incompletely reacts to the mixed fatty acid, the neutralization reaction temperature is controlled at 126℃~130℃, and the temperature is kept for 20±2min, and then the compound fatty acid salt with the neutralization degree of 95% is prepared for use. Then add 3 parts of dimethyl silicone oil, 5 parts of paraffin, 5 parts of glycerol monostearate, and 5 parts of ethylene bisstearic acid amide in another small emulsifying kettle. The temperature is 145℃~150℃. Under the conditions, stir, and then add the emulsifier L-804 parts, the quaternary ammonium salt cationic emulsifier 1 part mixed surfactants slowly to the active ingredients that have been stirred, and stir at a constant temperature for 20±2min to...

Embodiment 2

[0042] First, 30 parts by weight of palmitic acid, 20 parts of tallow oil, and 10 parts of rapeseed oil mixed fatty acids are put into a jacketed stirred reactor, and the temperature is raised to 70±1℃, and the neutralization rate is 90%. ±1% 30% liquid sodium hydroxide solution does not completely react to the mixed fatty acid. The neutralization reaction temperature is controlled at 120℃~125℃, and the temperature is kept at a constant temperature of 20±2min to prepare a compound fatty acid salt with a neutralization degree of 90%. . Then add 8 parts of dimethicone, 3.5 parts of sorbitol coconut oleate, and 5 parts of glycerol monostearate defoamer active ingredient in another small emulsifying kettle, and stir at the temperature of 120℃~125℃, Then add NP-304 parts of emulsifier, 0.5 part of diethylene glycol roseate emulsifier and mixed surfactants slowly to the active ingredients that have been evenly stirred, and stir at a constant temperature for 20±2 minutes to fully emul...

Embodiment 3

[0044] First, 20 parts of hardened oil, 20 parts of tallow oil, 10 parts of rosin, and 10 parts of coconut oil are mixed fatty acids according to the proportions by weight. Put the mixed fatty acid into a jacketed stirred reactor, heat up to 75±1℃, add and press for neutralization The rate requires 96±1% 30% liquid sodium hydroxide solution to incompletely react with mixed fatty acids, the neutralization reaction temperature is controlled at 130℃~135℃, and the temperature is kept for 20±2min, then a compound fat with a neutralization degree of 96% is prepared Salt, spare. Then add 10 parts of dimethyl silicone oil, 3 parts of tributyl phosphate, and 5 parts of glycerol monostearate defoamer active ingredient into another small emulsification kettle. Stir at a temperature of 125℃~128℃, and then Emulsifier S-603 parts and NP-302 parts are slowly added to the evenly stirred active ingredients, and stirred at constant temperature for 20±2min to fully emulsify the active ingredients...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com