Spring mounting tool

A technology for installing tooling and strips, which is applied in the manufacture of tools, hand-held tools, etc., can solve the problems of large return spring force, difficulty in controlling the direction of the installer, work-related injuries or product scrapping, etc., to achieve safety in the installation process, improve control difficulties, The effect of obvious labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

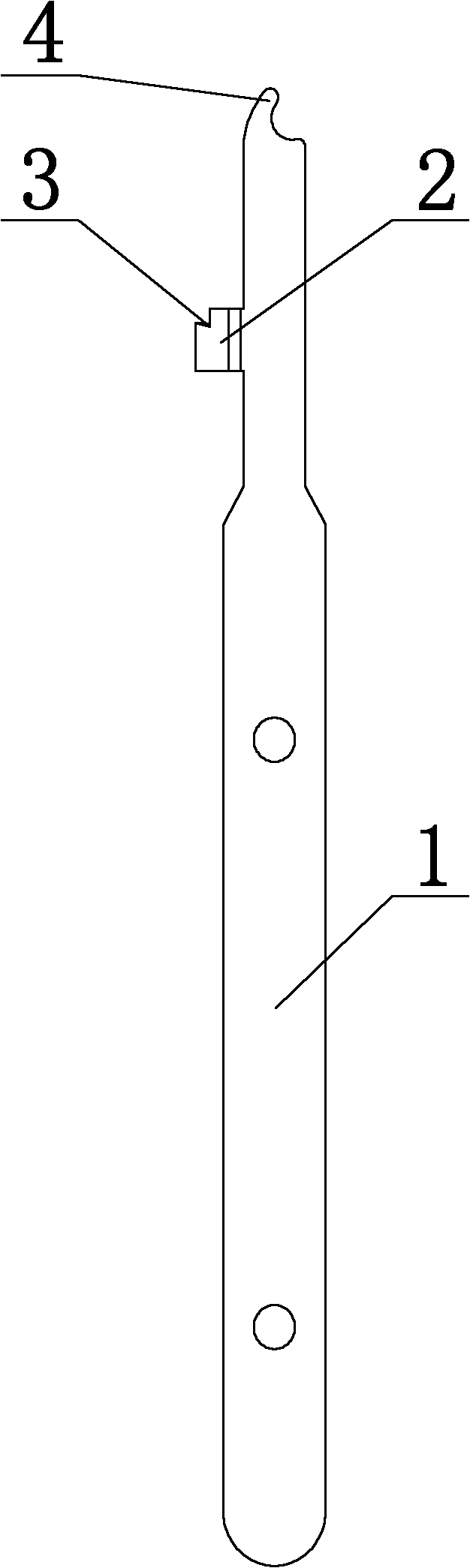

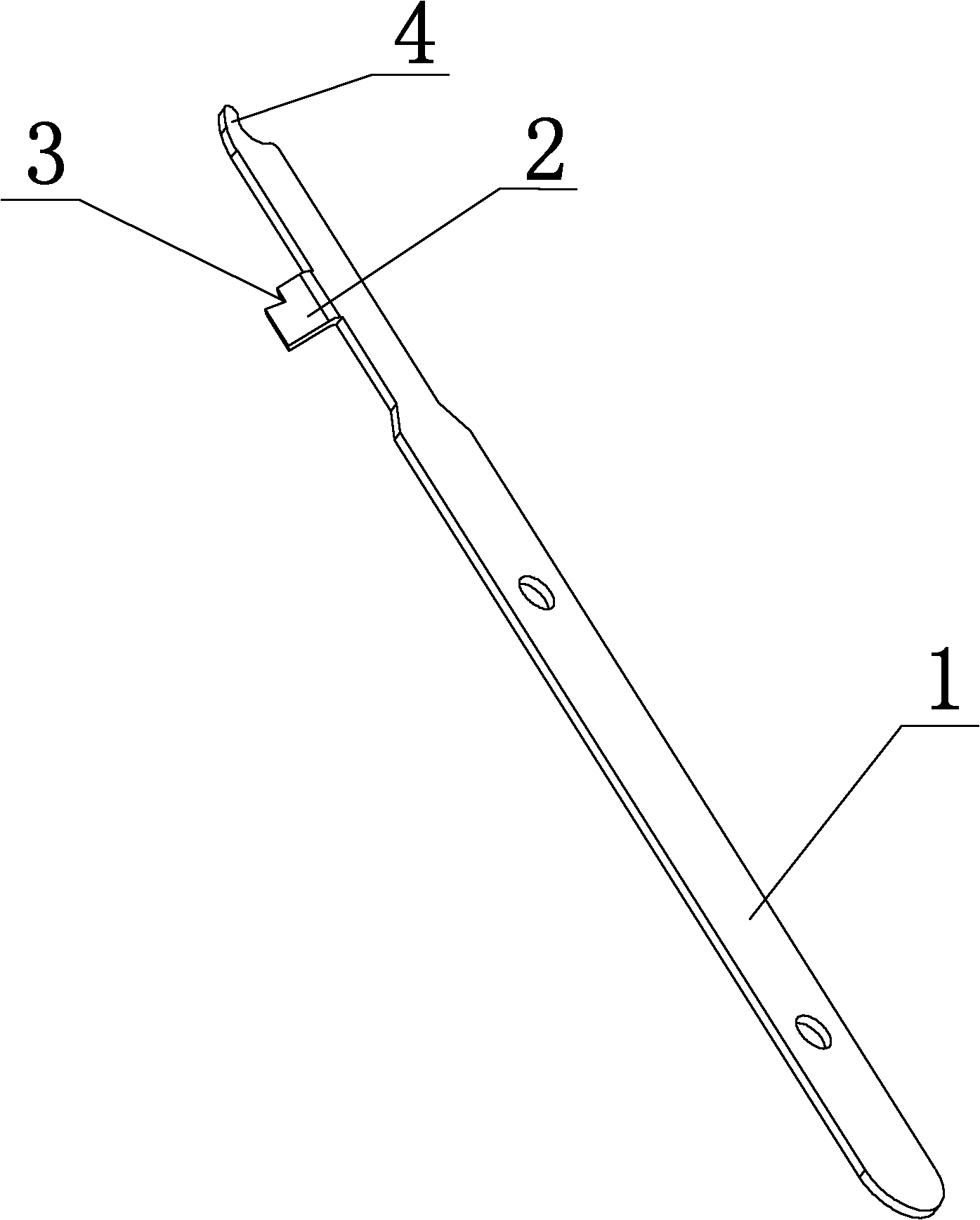

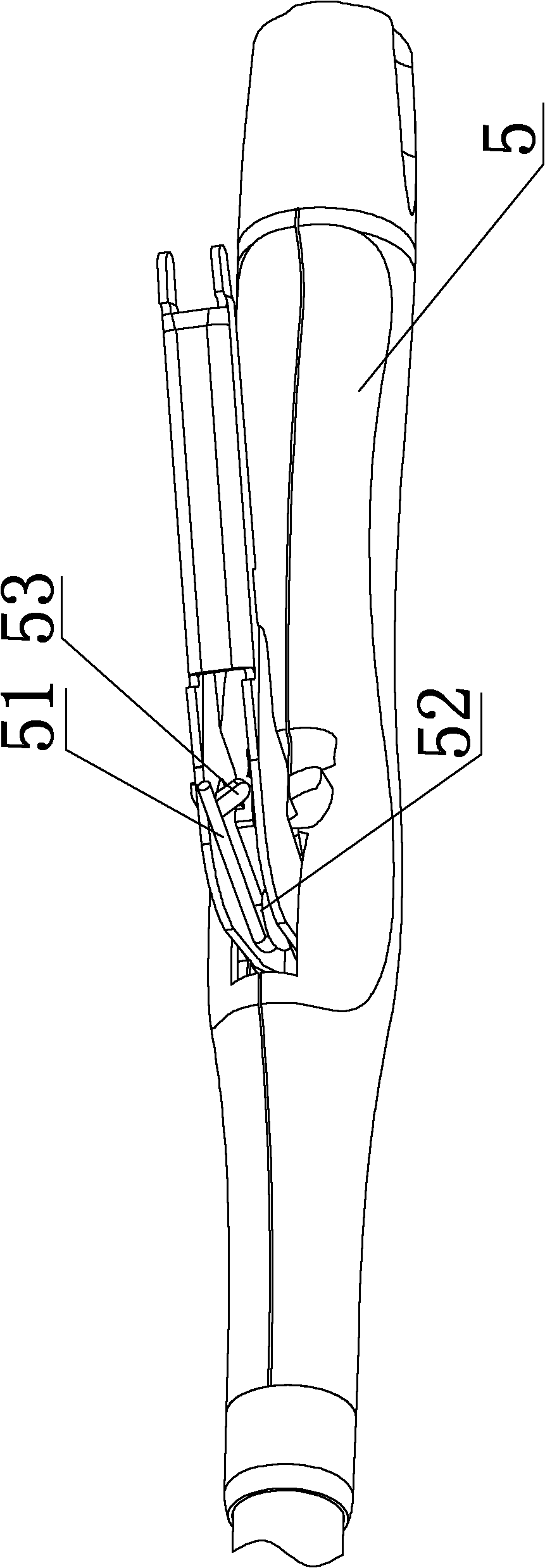

[0014] Such as figure 1 , figure 2 The shown spring installation tool includes a bar-shaped handle 1 with a rectangular cross section. A protrusion 2 is provided on the peripheral surface of the bar-shaped handle 1 , and a "V"-shaped notch 3 is opened on the protrusion 2 . One end of the bar-shaped handle 1 is also provided with a protruding support head 4 along its length direction, and the support head 4 is an arc-shaped head. The notch 3 is arranged on the side of the protrusion 2 facing the support head 4, and the distance between the protrusion 2 and the support head 4 should be less than as image 3 , Figure 4 The distance between the movable handle boss 53 and the return spring pin 52 of the tubular digestive tract stapler shown.

[0015] How to use: first clamp the gap 3 on the bar handle 1 to the free end of the return spring 51 of the tubular digestive tract stapler 5, then compress the return spring 51 so that the support head 4 of the bar handle 1 is against t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com