Manufacturing method for mini quartz glass atomic gas chamber

A quartz glass and atomic gas chamber technology, applied in the field of atomic gas chamber preparation, can solve the problems of poor chamber purity, difficult manufacturing process, and difficulty in mass production, and achieves reduced energy consumption, broad market application prospects, and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

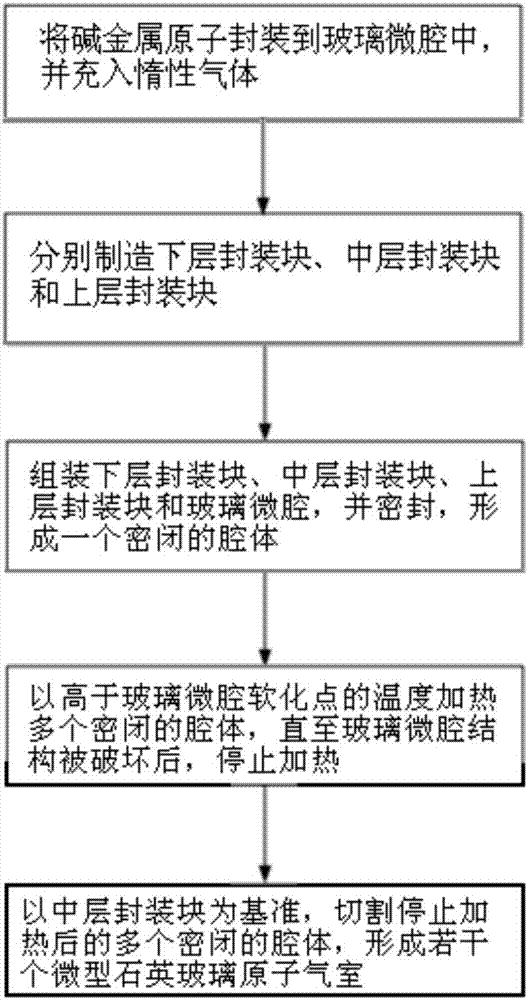

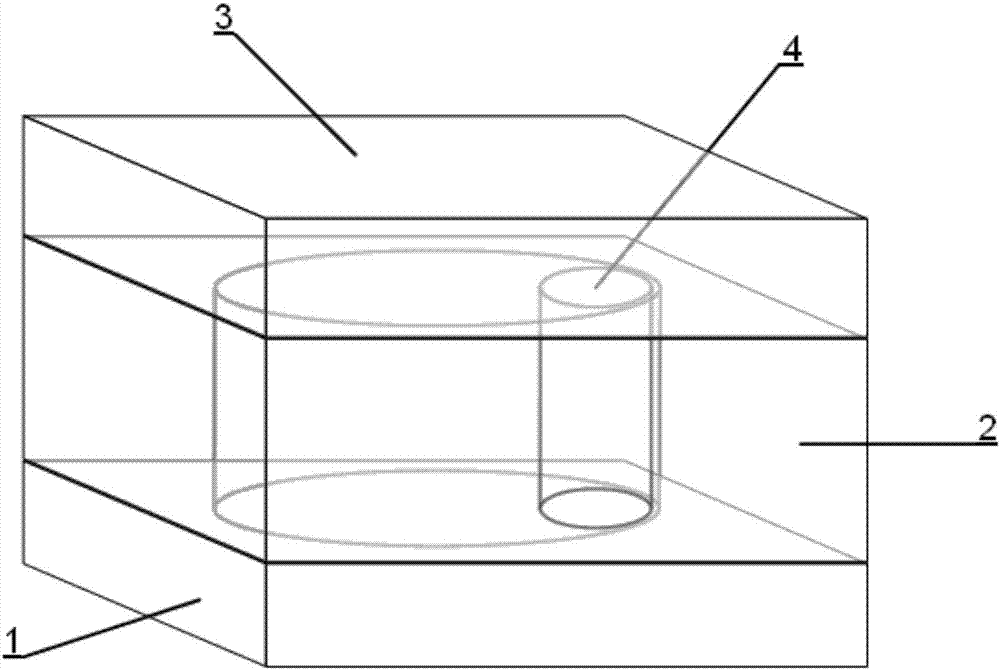

[0031] Such as Figure 1~2 Shown, a kind of manufacture method of miniature quartz glass atomic gas chamber comprises the steps:

[0032] Step 1: encapsulate the alkali metal atoms into the glass microcavity 4 and fill it with an inert gas;

[0033] The second step: manufacturing the lower packaging block 1, the middle packaging block 2 and the upper packaging block 3 respectively;

[0034] The third step: install the lower packaging block 1 on one end of the middle packaging block 2, then place the glass microcavity 4 encapsulated with alkali metal atoms in the middle packaging block 2, and then install the upper packaging block 3 on the other side of the middle packaging block 2 One end, and sealed to form a closed cavity;

[0035] Step 4: heating multiple closed cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com