A UAV high-precision full-frame tilt photogrammetry device

An oblique photogrammetry and full-frame technology, which is applied in the direction of camera devices, motor vehicles, aircraft parts, etc., can solve the problems of high-definition camera damage, wide-angle real-time adjustment, etc., to achieve excellent results, reduce equipment costs, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

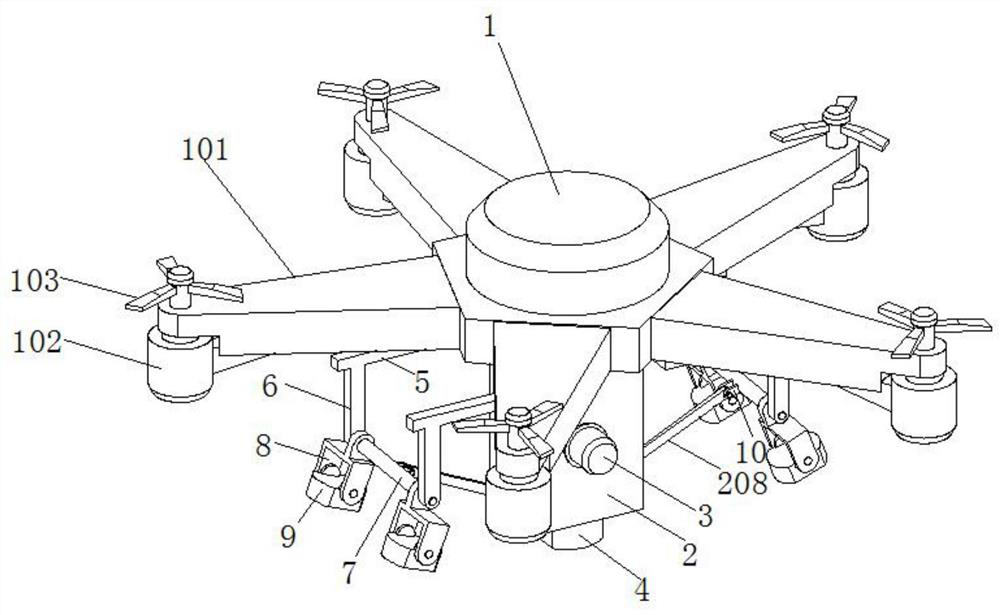

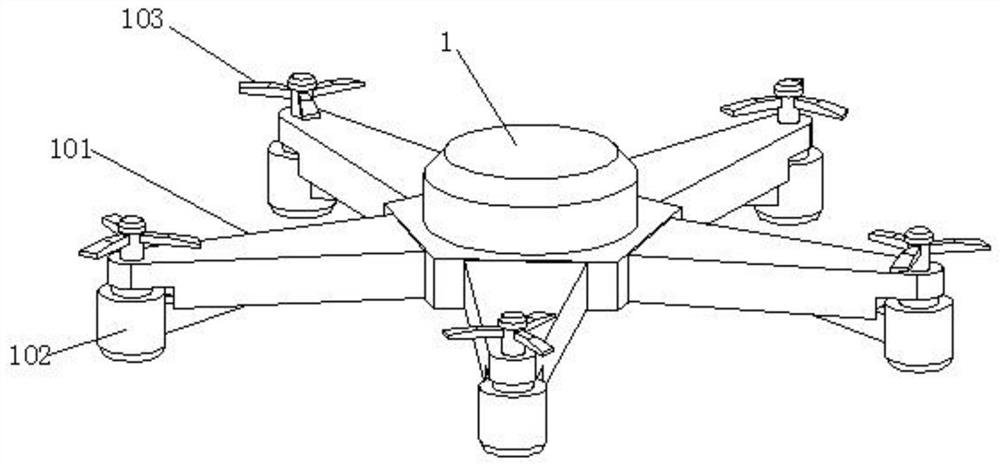

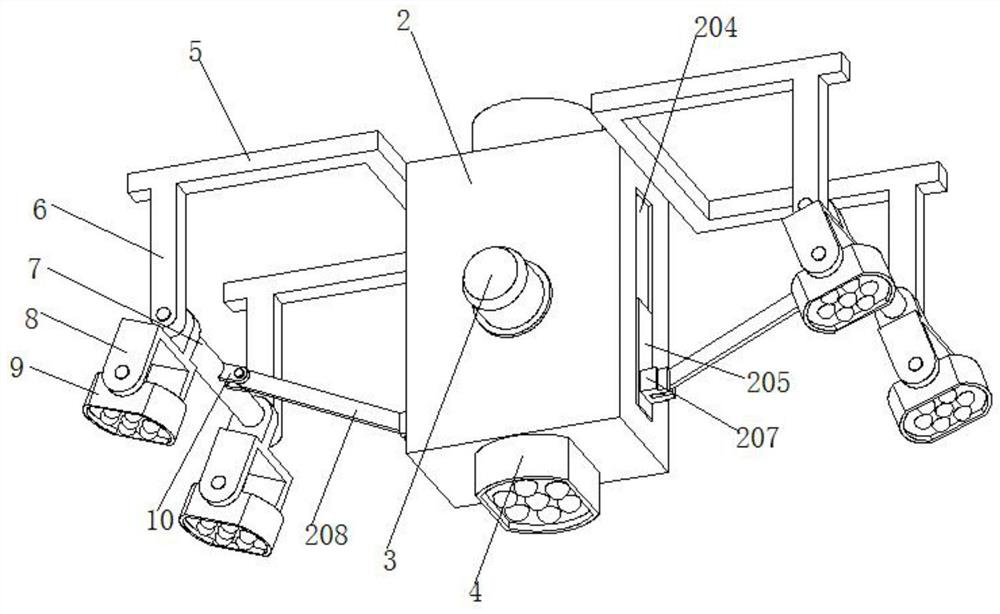

[0031]This embodiment 1 introduces a UAV high-precision full-frame tilt photogrammetry device, refer to the attached figure 1 , attached figure 2 And attached Figure 7 , which includes a UAV body 1, a number of rotor arms 101 are evenly connected to the UAV body 1, and a drive motor 102 is fixed on the lower surface of the outer end of each rotor arm 101, and the output shaft of the drive motor 102 passes through the rotor The upper end of the machine arm 101 is provided with a propeller 103 . When setting specifically, there are five rotorcraft arms 101 connected on the drone body 1 in this embodiment, and the five rotorcraft arms 101 are connected to the drone body 1 in an annular array, and the drone passes through A plurality of symmetrically arranged rotor arms 101 drive the mechanism together, so that the load-bearing capacity of the entire drone body 1 is not less than 8kg during flight, and the flight process is more balanced and stable. In addition, in order to s...

Embodiment 2

[0035] Embodiment 2 is a further improvement made on the basis of Embodiment 1, below in conjunction with the attached Figure 1~6 Explain it further.

[0036] Embodiment 2 discloses an improved UAV high-precision full-frame oblique photogrammetry device based on Embodiment 1. Refer to the attached figure 1 , attached figure 2 And attached Figure 7 , which includes a UAV body 1, a number of rotor arms 101 are evenly connected to the UAV body 1, and a drive motor 102 is fixed on the lower surface of the outer end of each rotor arm 101, and the output shaft of the drive motor 102 passes through the rotor The upper end of the machine arm 101 is provided with a propeller 103 . When setting specifically, there are five rotorcraft arms 101 connected on the drone body 1 in this embodiment, and the five rotorcraft arms 101 are connected to the drone body 1 in an annular array, and the drone passes through A plurality of symmetrically arranged rotor arms 101 drive the mechanism t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com