Modification method of attapulgite

An attapulgite modification technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of reduced modification efficiency, weak adhesion, and long soaking time of attapulgite, so as to shorten the purification time. and the time required for modification, the effect of improving modification activity, and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A, the purification of attapulgite, take attapulgite 1kg and pulverize, be pulverized to particle size and be 2 orders, the attapulgite after pulverizing is added in the clear water of 10kg, stir evenly, after soaking for 10 hours, centrifuge for 10min, The rotational speed of the centrifuge is 1500r / min, and after the centrifugation, the upper suspension is filtered and dried to obtain the primary product of attapulgite;

[0024] B, the modification of attapulgite, utilize sodium carbonate configuration concentration to be the sodium carbonate solution of 2.5%, put the preliminary product of described attapulgite into sodium carbonate solution, and stir and heat, described stirring speed The heating temperature is 60r / min, and the heating temperature is maintained at 60-85°C; during the stirring process, sodium bicarbonate and sodium hydroxide particles are added while stirring, and the sodium bicarbonate and sodium hydroxide particles added to the sodium carbonate solu...

Embodiment 2

[0030]A, the purification of attapulgite, get attapulgite 1kg and pulverize, be pulverized to particle size and be 16 orders, the attapulgite after pulverizing is added in the clear water of 15kg, stir well, after soaking for 15 hours, centrifuge for 25min, the The rotating speed of described centrifugal is 1800r / min, obtains the initial product of attapulgite through steps such as drying after centrifugal;

[0031] B, the modification of attapulgite, utilize sodium carbonate configuration concentration to be 1L of sodium carbonate solution of 4.0%, put the preliminary product of described attapulgite into sodium carbonate solution, and stir and heat, described stirring The speed is 300r / min, and the heating temperature is maintained at 60-85°C; during the stirring process, sodium bicarbonate and sodium hydroxide particles are added while stirring, and the sodium bicarbonate added to the sodium carbonate solution The quality of sodium hydroxide and sodium hydroxide all account...

Embodiment 3

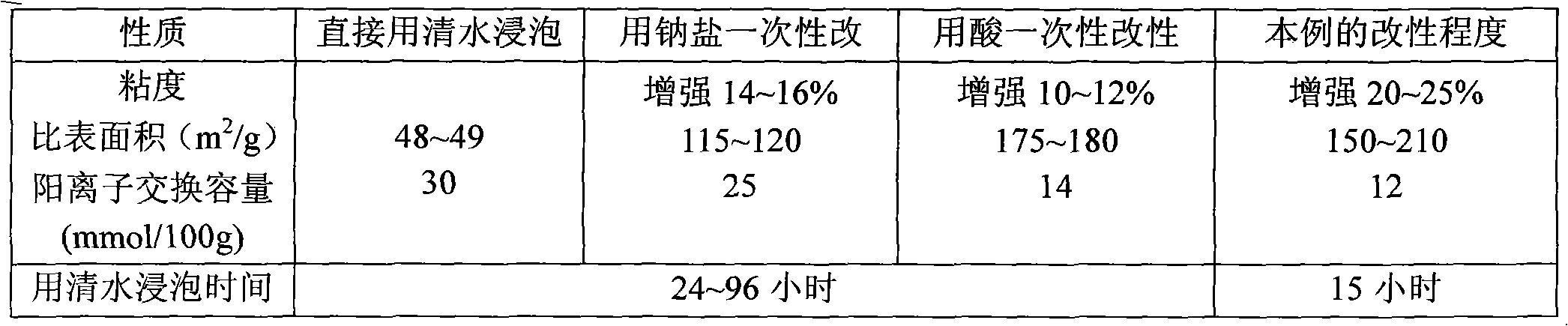

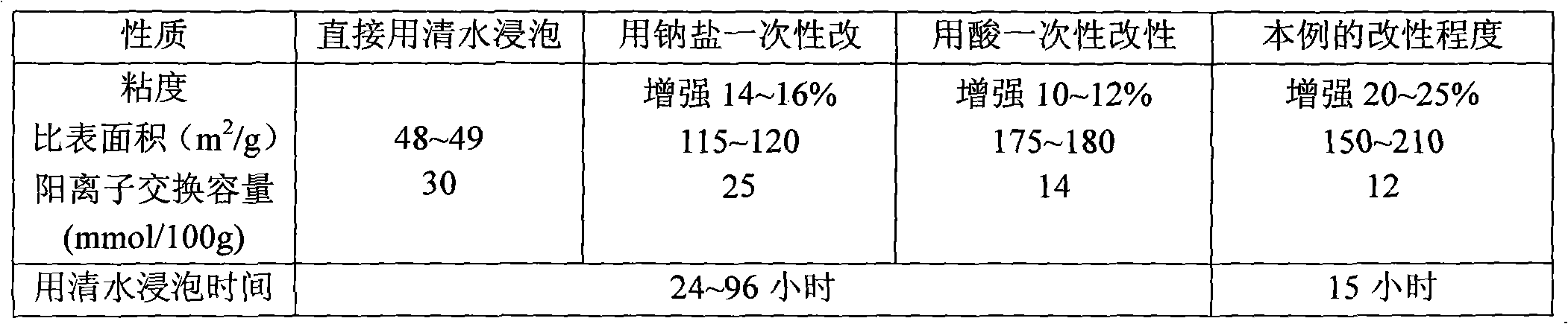

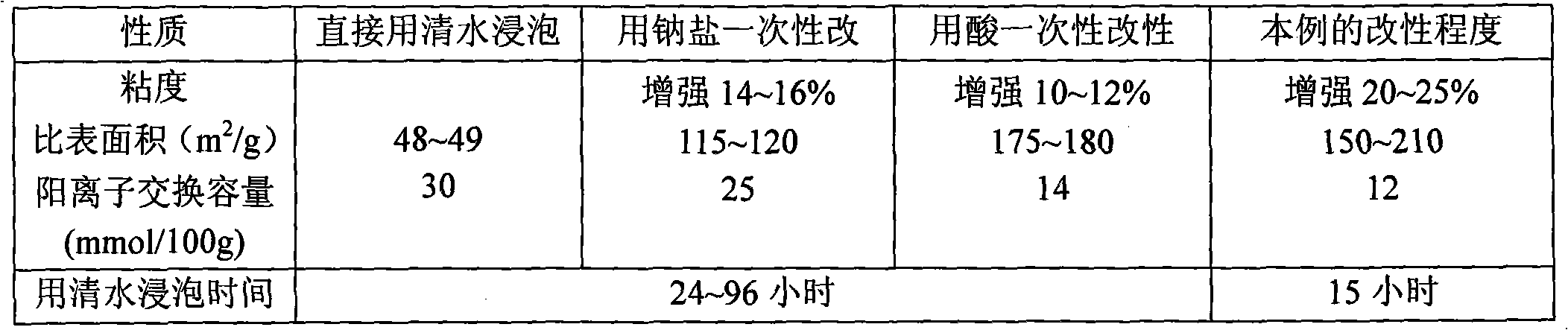

[0037] The difference from Example 2 is that in the step A, the attapulgite is crushed until the particle size is 5 mesh, and the centrifugation time of the step A is controlled to 10 minutes. It has been determined that compared with other attapulgite sodium salts and acidification modification methods, this example has a great breakthrough in modification degree and other aspects, as shown in the following table:

[0038]

[0039] That is to say, the viscosity of the attapulgite treated in this example is 20-25% higher than the viscosity of the attapulgite treated with clear water for 24 hours, and 10-15% higher than the viscosity of the attapulgite treated with acidification alone; the attapulgite treated in this example The specific surface area of attapulgite is 3 to 5 times higher than that of attapulgite soaked in water for 24 hours. This is also a breakthrough in the purification of attapulgite. The overall modification degree of attapulgite in this example is bett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com