Preparation method of modified nanometer magnesium-aluminum composite fire retardant

A nano-magnesium-aluminum composite technology, which is applied in the field of preparation of modified nano-magnesium-aluminum composite flame retardants, can solve the problem of high cost and achieve the effect of simple intermediate process, less dosage and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

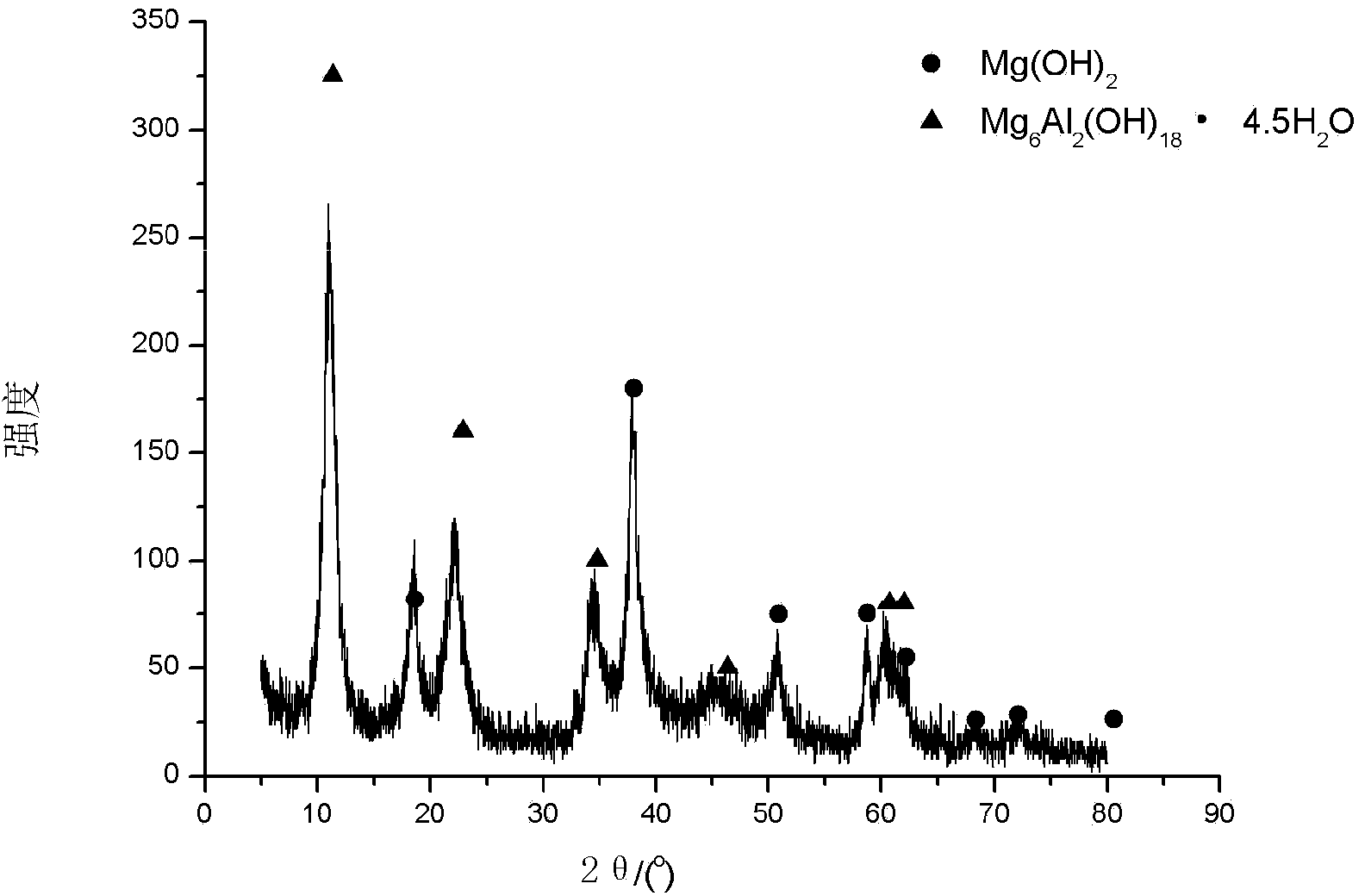

[0033] Weigh 19.2g magnesium nitrate hexahydrate and 7.03g aluminum nitrate nonahydrate at room temperature, dissolve in 50ml AE 9 C-Na solution with a mass concentration of 0.132g / L was added to a 250ml three-neck flask, and heated to 65°C in a water bath; 9g of sodium hydroxide was dissolved in 100ml of water, and heated to the same temperature in a water bath; at 65°C, under vigorous stirring, Slowly add the lye to the three-necked bottle, after 15 minutes, the dropwise addition is completed, continue to stir for 0.5h, stand at room temperature for 1.5h, filter with suction, wash with 800ml of water, wash with 20ml of absolute ethanol, and put the obtained filter cake into an oven at 110°C Dry for 4h. A modified nano-magnesium-aluminum composite flame retardant is obtained. The obtained powder was analyzed by XRD, and the test results were as follows: figure 2 .According to the XRD test data, the Scherrer formula calculation shows that the size of the lamellar magnesium-...

Embodiment 2

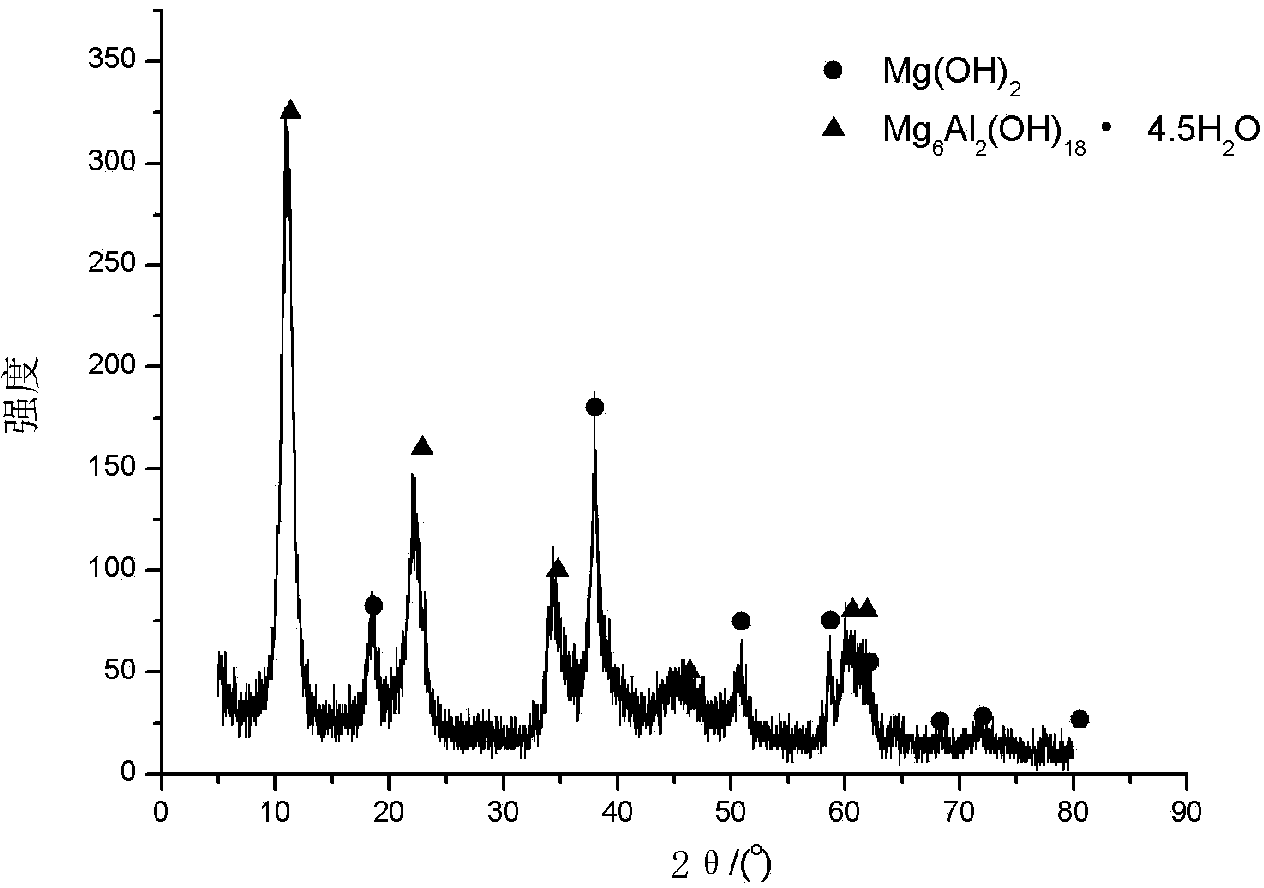

[0035] Weigh 18.45g of magnesium sulfate heptahydrate and 7.03g of aluminum nitrate nonahydrate at room temperature, dissolve them in 50ml of APG (1214) solution with a mass concentration of 0.658g / L, add them to a 250ml three-necked flask, and heat to 85°C in a water bath; take 11.55g Dissolve 1 g of potassium hydroxide in 100ml of water, heat the water bath to the same temperature; slowly drop the lye into the three-necked flask under vigorous stirring at 85°C, continue stirring for 1 hour after 20 minutes of dropping, leave at room temperature for 2 hours, and filter with suction , washed with 800ml of water, washed with 20ml of absolute ethanol, and dried in an oven at 110°C for 4 hours. A modified nano-magnesium-aluminum composite flame retardant is obtained. Test process is with embodiment 1, and XRD test is as image 3 . The results are shown in Table 1.

Embodiment 3

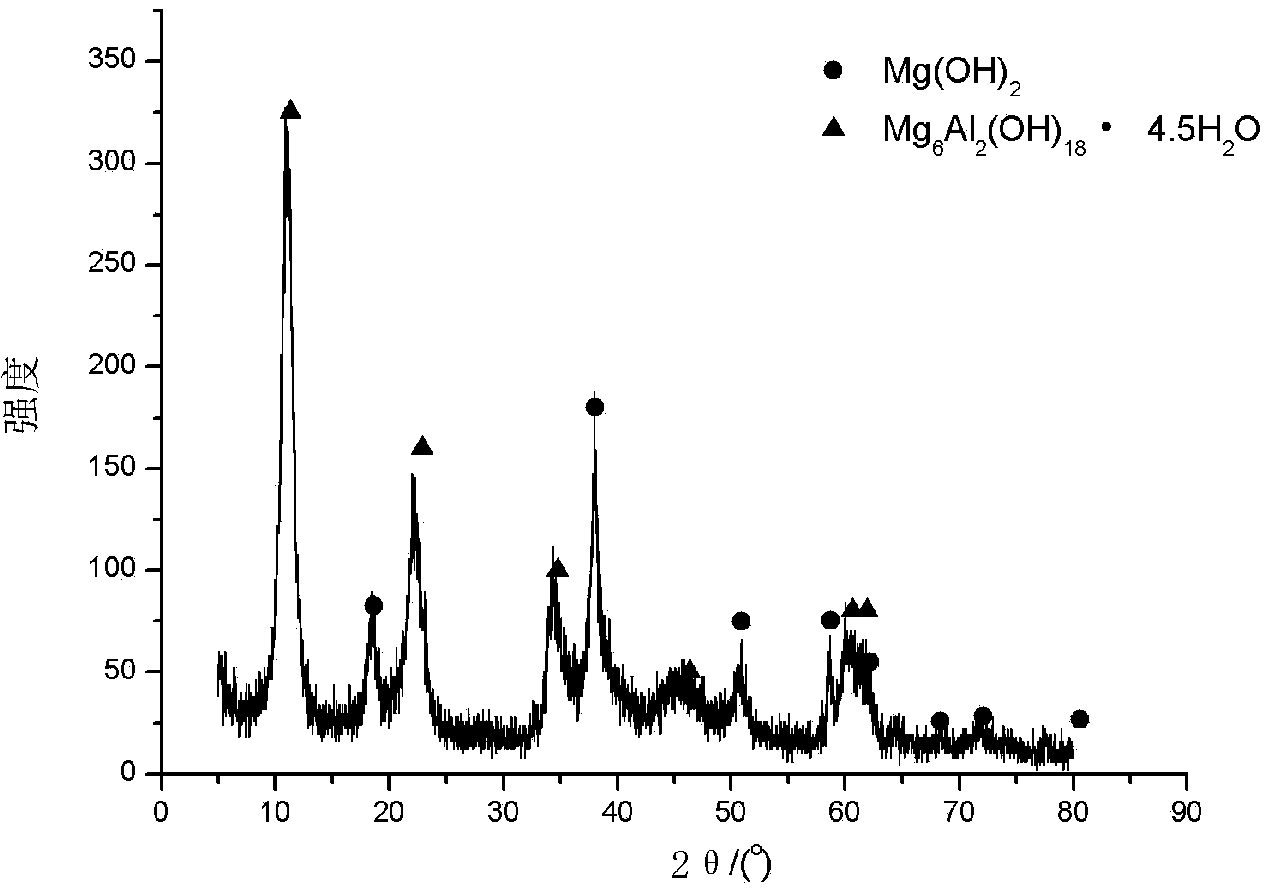

[0037] Weigh 19.2g of magnesium nitrate hexahydrate and 7.03g of aluminum nitrate nonahydrate at room temperature, dissolve them in 50ml of PA-Na solution with a mass concentration of 1.314g / L, add them to a 250ml three-necked flask, and heat to 85°C in a water bath; prepare 100ml concentration 2.06mol / L ammonia solution, heated to the same temperature in a water bath; slowly add the lye dropwise into the three-necked flask under the condition of vigorous stirring at 85°C, after 30 minutes of dropping, continue to stir for 2h, stand at room temperature for 3h, pump Filter, wash with 800ml of water, wash with 20ml of absolute ethanol, and put the obtained filter cake into an oven to dry at 110°C for 4h. A modified nano-magnesium-aluminum composite flame retardant is obtained. Test process is with embodiment 1, and XRD test is as Figure 4 . The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com