Preparation method for antibacterial type textile fabric

A technology of textile fabrics and textile fibers, which is applied in the direction of textiles and papermaking, rayon manufacturing, and fiber chemical characteristics, etc. It can solve the problem of reduced thermal insulation effect of textile fabrics, high tear strength, reduced air permeability and thermal insulation effects of textile fabrics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

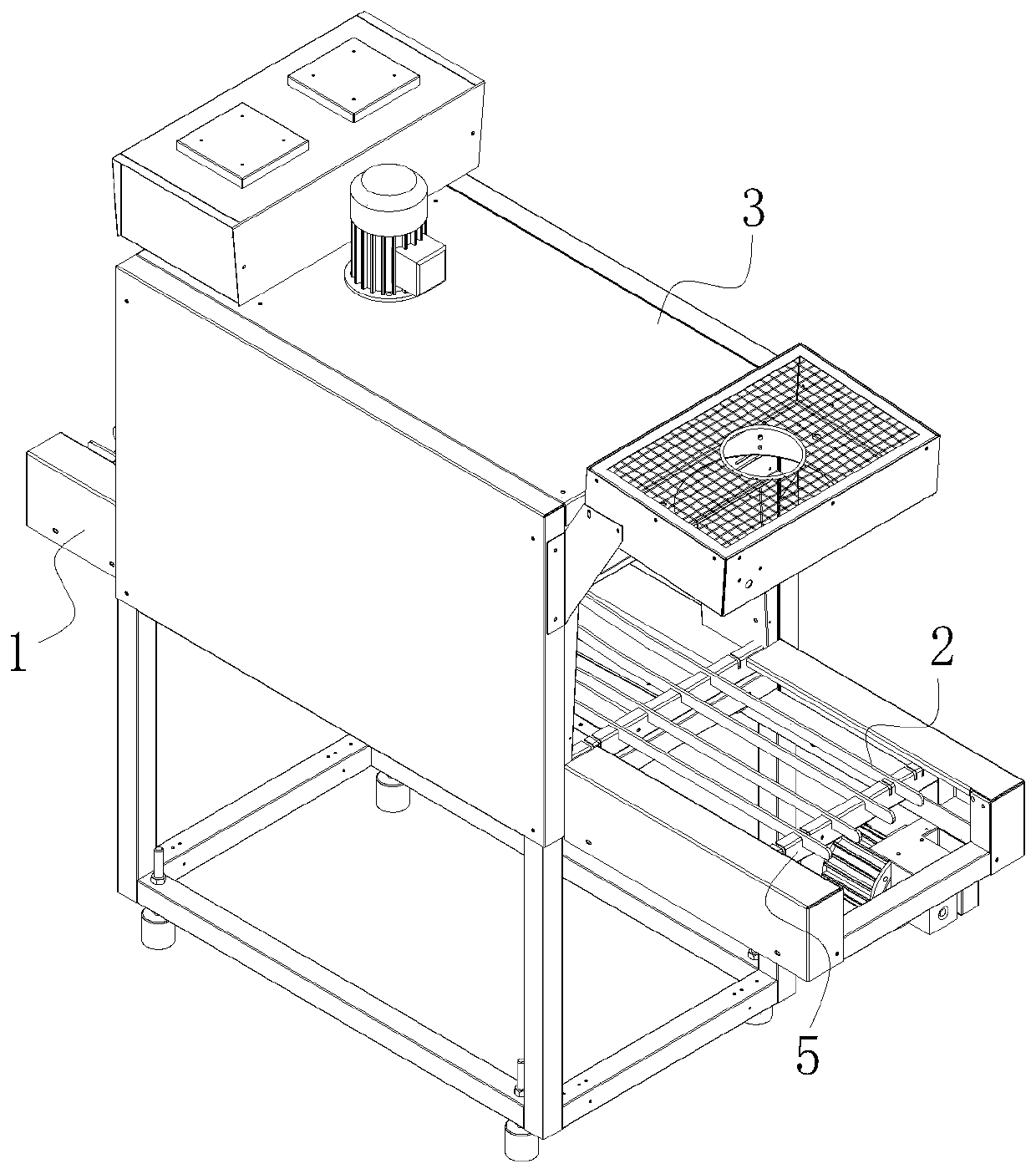

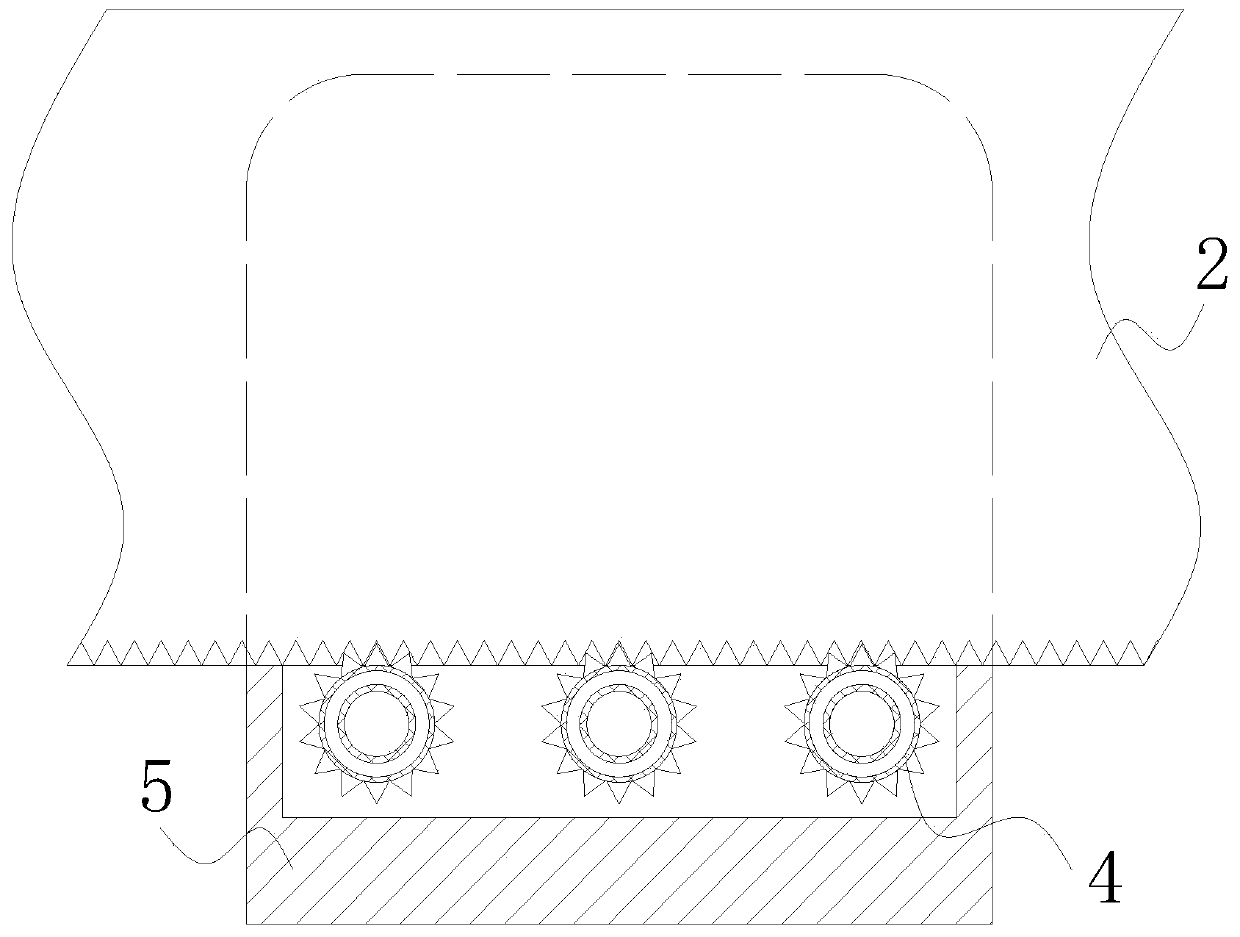

[0029] like Figure 1-Figure 4 Shown, the preparation method of a kind of antibacterial textile fabric of the present invention, antibacterial textile fabric comprises the following components of each weight portion:

[0030] 35 parts of polyvinyl alcohol, 21 parts of chitosan, 30 parts of distilled water, 17 parts of bamboo fiber, 8 parts of far-infrared ceramic powder, 7 parts of honeysuckle, 3 parts of garlic essential oil, 10 parts of deionized water, 5 parts of single-layer graphene and 6 parts of polymer elastomer; far-infrared ceramic coating (containing nano-titanium oxide coating) has a catalytic oxidation function, and under the irradiation of sunlight (especially ultraviolet rays), OH- is generated, which can effectively remove sulfide, ammonia and odorous substances. And it has a bactericidal function; at the same time, the mixture of far-infrared ceramic powder and polymer elastomer can improve the air permeability of the textile fabric when the textile fabric is ...

Embodiment approach

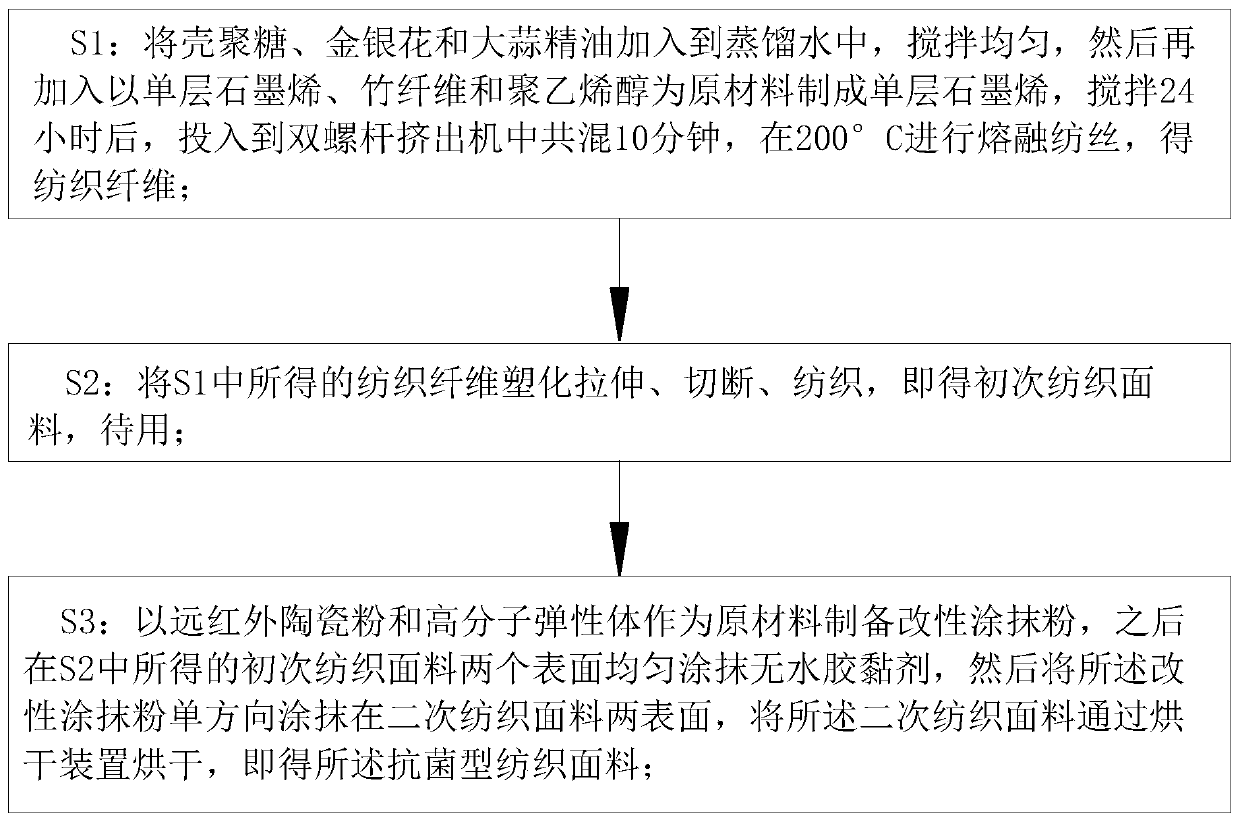

[0031] As an embodiment of the present invention, the preparation method of the antibacterial textile fabric comprises the following steps:

[0032] S1: Add chitosan, honeysuckle and garlic essential oils to distilled water, stir evenly, then add single-layer graphene made of single-layer graphene, bamboo fiber and polyvinyl alcohol as raw materials, stir for 24 hours, and put into Blending in a twin-screw extruder for 10 minutes, and performing melt spinning at 200°C to obtain textile fibers;

[0033] S2: Plasticizing, stretching, cutting, and spinning the textile fibers obtained in S1 to obtain the primary textile fabric for use;

[0034] S3: Prepare modified smear powder with far-infrared ceramic powder and polymer elastomer as raw materials, and then apply anhydrous adhesive evenly on both surfaces of the primary textile fabric obtained in S2, and then apply the modified smear powder in one direction Apply on both surfaces of the secondary textile fabric, and dry the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com