Modified epoxy organosilicon high-thermal-conduction insulating impregnating paint and preparation method thereof

An insulating impregnating varnish and modification technology, applied in the coating and other directions, can solve the problems of poor fluidity, unfavorable, large viscosity influence, etc., achieve high yield, achieve mass production, and complete the effect of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Compound shown in formula (Ia) (i.e. R in formula (I)0 Propyl) Preparation: Weigh 15.8g (0.073mol) N-butylpyridinium bromide ([bpy]Br) and 8g (0.073mol) (sodium tetrafluoroborate) NaBF 4 In a plastic washing bottle, add 100 mL of acetone as a solvent, stir magnetically, condense and reflux at room temperature, react for 12 hours, let stand, filter under reduced pressure, discard the white solid NaBr, and obtain a light yellow clear filter night, and filter to a light yellow clear Add 100mL of dichloromethane to the solution, and a white precipitate precipitates out. Suction filtration under reduced pressure, and the filter is concentrated by rotary evaporation to remove acetone and dichloromethane. The obtained yellow oily liquid is vacuum-dried at 60°C for 8 hours to obtain the product formula (Ia ) Compound [bpy]BF 4 13.8g, yield 85.2%;

[0072]

Embodiment 2

[0074] Compound shown in formula (Ib) (i.e. R in formula (I) 0 For the preparation of methyl): 28.2g (0.15mol) of brominated N-ethylpyridine was added to an Erlenmeyer flask containing 50mL of acetone, and 16.5g (0.15mol) of NaBF was added 4 , magnetic stirring at room temperature for 10 h, filtration, rotary evaporation, removal of volatile acetone, and vacuum drying to obtain 25.16 g of the compound represented by formula (Ib) as a white solid, with a yield of 86.5%, m.p.53.2-53.6°C;

[0075]

Embodiment 3

[0077] This example provides a preparation method of modified epoxy resin and the modified epoxy resin prepared by this method. The raw materials of the modified epoxy resin include: epoxy resin E-51 80g, vinyl-containing hydrophobic Type hexagonal boron nitride nanosheets (M-BNNSs) 6g, methyl methacrylate (MAA) 13g, butyl acrylate (BA) 7g. The solvent used in the preparation process is the third solvent-25g of n-butanol, and the initiator is 4g of dibenzoyl peroxide (BPO).

[0078] Its preparation method specifically includes:

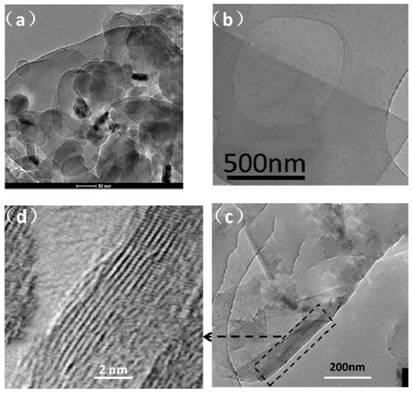

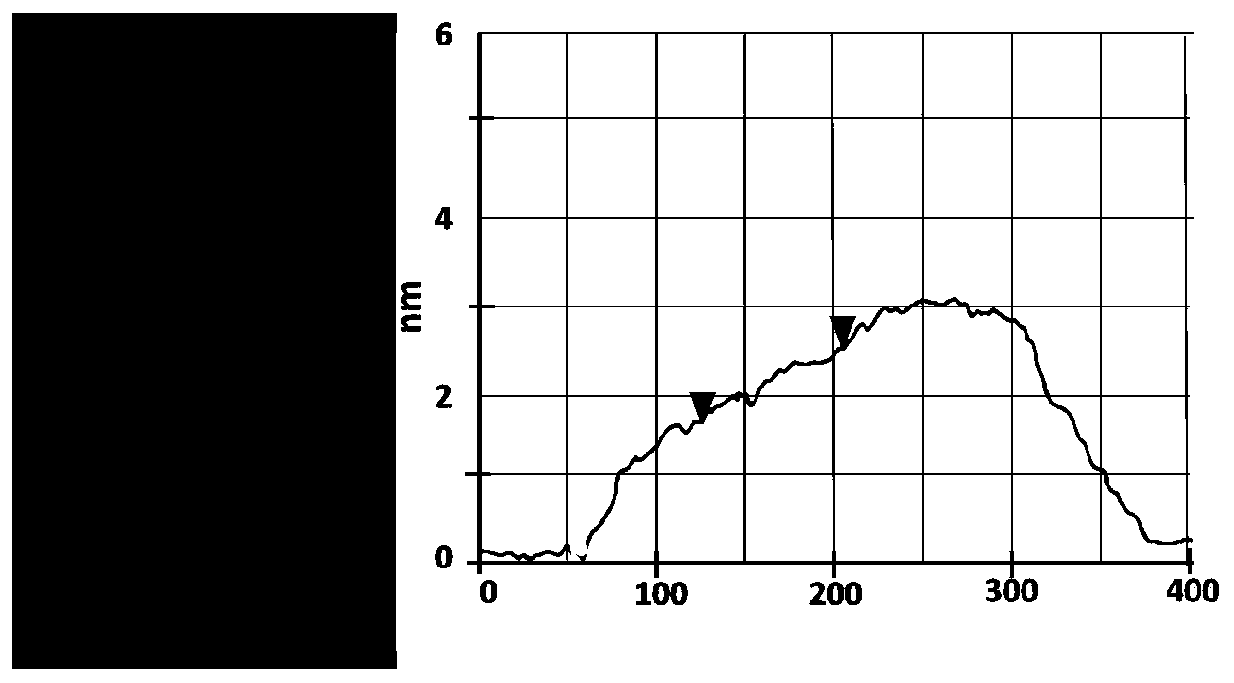

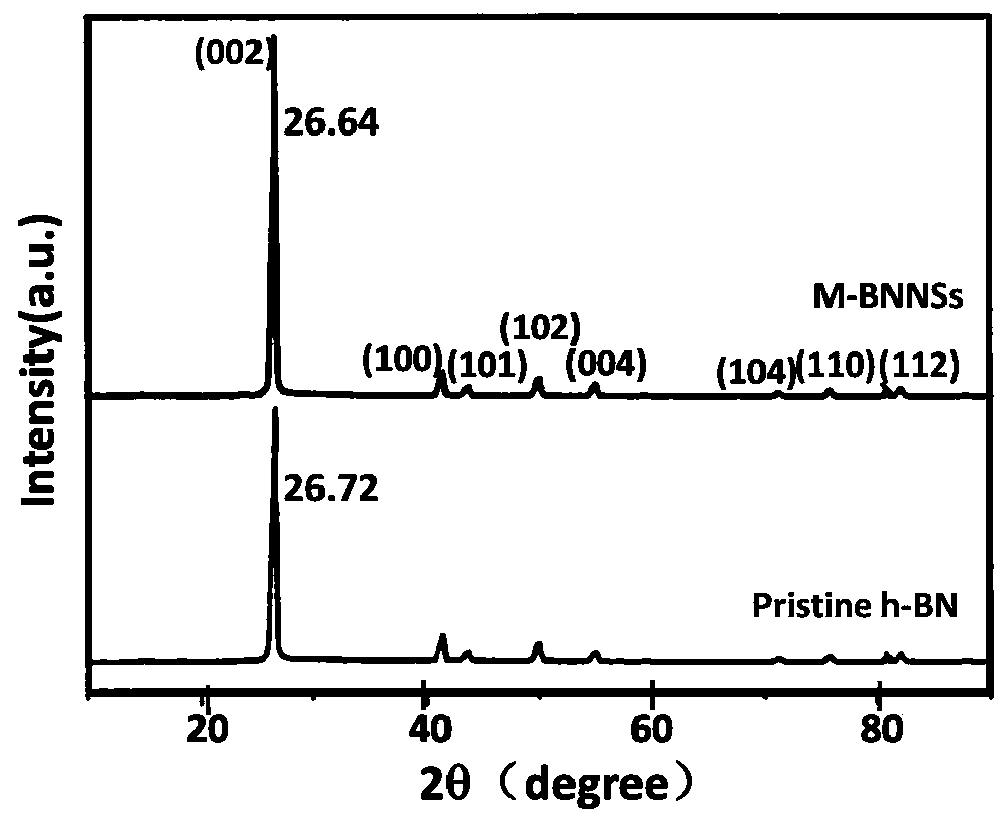

[0079] (a) Preparation of hydrophobic hexagonal boron nitride nanosheets containing vinyl groups:

[0080] (1) Hydroxylated hexagonal boron nitride is prepared by surface hydroxylation modification of hexagonal boron nitride. In the three-necked reaction flask, add the 5mol / L aqueous sodium hydroxide solution prepared in advance, and mechanically stir for 10 hours under the condition of heating in an oil bath at about 100°C. The resulting mixture is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com