Preparation method of silicon-based hybrid aerogel balls for removing copper ions in water

A technology of airgel pellets and copper ions, which is applied in chemical instruments and methods, inorganic chemistry, water pollutants, etc., can solve the problems of difficult regeneration and short service life of adsorbents, and achieve low recycling costs and good ball formation Good, the effect of reducing recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

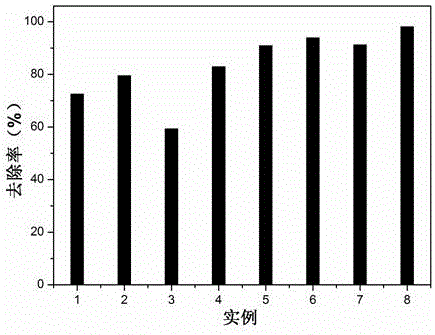

Examples

Embodiment 1

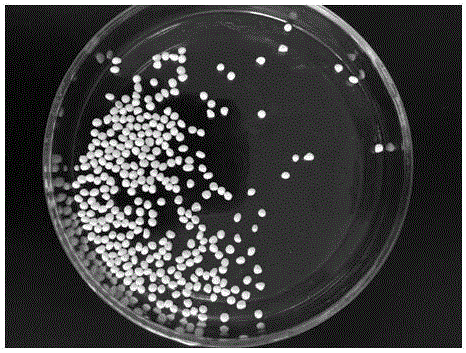

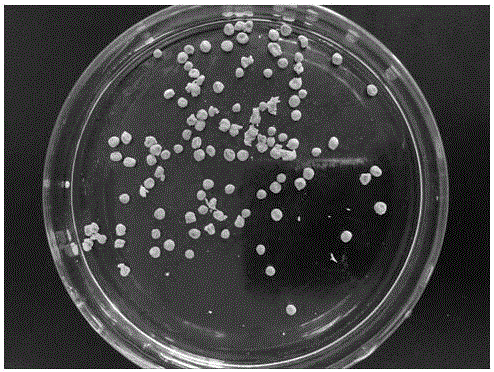

[0029] After adding 1.5mg of sodium alginate to 100mL of water to fully dissolve, the solution uses an ultrasonic cleaner to remove air bubbles in the solution. Mix the sodium alginate aqueous solution with water glass at a volume ratio of 4:1, stir evenly, and drop the mixed solution at a height of 25 cm into the continuously stirring calcium chloride aqueous solution, the concentration of calcium chloride is 25 mg / L, and the volume is 100 mL. Form into pellets.

[0030] Soak the balls in ethanol for 8 hours, then soak the balls in the ethanol solution of 15% silane coupling agent KH550, take out the balls after 8 hours, wash them with water and absolute ethanol, and put them at 60℃ The samples were obtained by drying.

Embodiment 2

[0032] After adding 1.5mg of sodium alginate to 100mL of water to fully dissolve, the solution uses an ultrasonic cleaner to remove air bubbles in the solution. Mix the sodium alginate aqueous solution with water glass at a volume ratio of 5:1, stir evenly, and drop the mixed solution at a height of 25 cm into the continuously stirring calcium chloride aqueous solution, the concentration of calcium chloride is 25mg / L, and the volume is 100mL. Form into pellets.

[0033] Soak the balls in ethanol for 8 hours, then soak the balls in the ethanol solution of 15% silane coupling agent KH550, take out the balls after 8 hours, wash them with water and absolute ethanol, and put them at 60℃ The samples were obtained by drying.

Embodiment 3

[0035] After adding 1.5mg of sodium alginate to 100mL of water to fully dissolve, the solution uses an ultrasonic cleaner to remove air bubbles in the solution. Mix the sodium alginate aqueous solution with water glass at a volume ratio of 6:1, stir evenly, and drop the mixed solution at a height of 25 cm into the continuously stirring calcium chloride aqueous solution, the concentration of calcium chloride is 25mg / L, and the volume is 100mL. Form into pellets.

[0036] Soak the balls in ethanol for 8 hours, then soak the balls in an ethanol solution of 15% silane coupling agent KH550, take out the balls after 8 hours, wash them with water and anhydrous, and dry them at 60°C Get a sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com