Modifying method of quick lime for sintering

A quicklime and modification technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems that it is difficult to give full play to the performance of quicklime, and the modification steps of quicklime are simple, so as to achieve the improvement of mechanical properties and the modification effect good, good stability

Pending Publication Date: 2018-12-28

SHANDONG TAISHAN STEEL GROUP

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most sintering plants do not modify the quicklime or the modification steps are simple, it is difficult to give full play to the performance of the quicklime

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

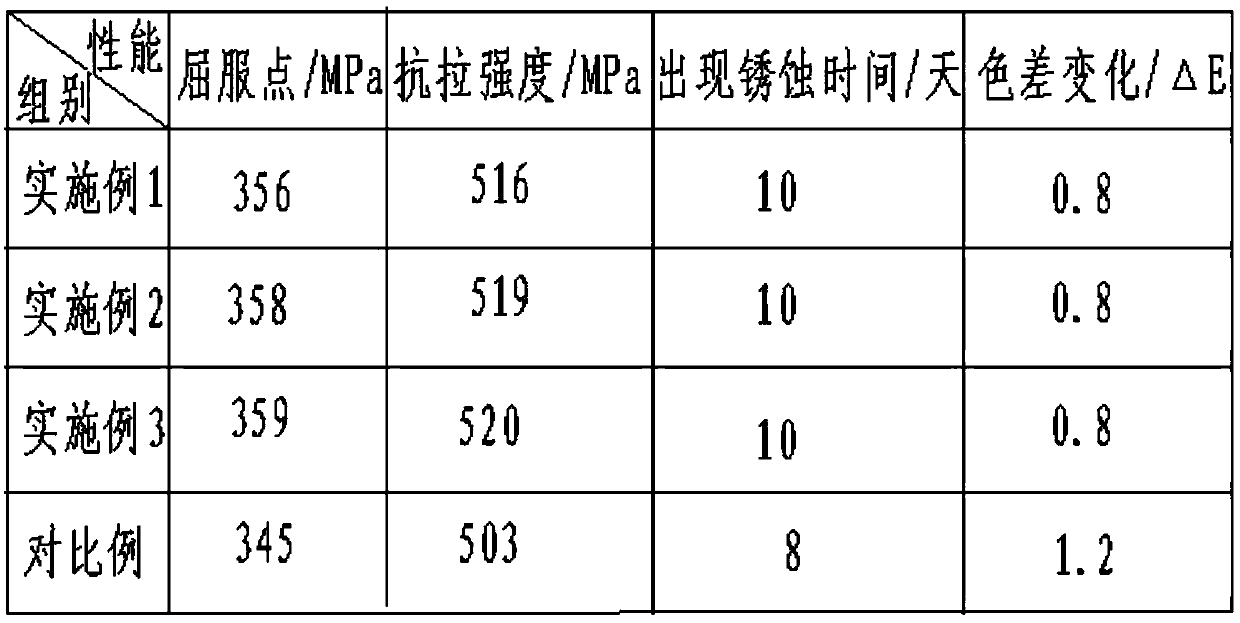

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a modifying method of quick lime for sintering. The modifying method comprises the following steps of (1) crushing quick lime which is not treated; (2) adding water to the quick lime which is crushed in the step (1), performing sufficient stirring, and then performing standing for 30-40min; (3) adding sodium hydroxide solid to a solution prepared in the step (2), and performing uniform stirring; (4) heating the solution prepared in the step (3) to 60-70 DEG C, and continuing performing stirring; (5) mixing sodium sulfide with water in the mass ratio of the sodium sulfide to the water being 1 to 100 so as to obtain a sodium sulfide aqueous solution; (6) uniformly adding the sodium sulfide aqueous solution which is prepared in the step (5) to the solution prepared inthe step (4); (7) charging carbon dioxide to the solution prepared in the step (6), after the solution become turbid, continuing charging the carbon dioxide until a clarifying layer appears at the upper layer of the solution; and (8) filtering the solution prepared in the step (7). According to steel products prepared from the modified quick lime, the mechanical property is obviously improved, the life is prolonged, and the steel products are excellent in quality and high in stability.

Description

technical field The invention relates to the technical field of quicklime modification, in particular to a method for modifying quicklime for sintering. Background technique Sintering is an important step for iron and steel enterprises to process iron concentrate, which can provide raw materials with good air permeability and qualified hardness for steelmaking. An appropriate amount of alkaline flux is usually added during sintering. One is to obtain sintered ore with a certain alkalinity, which reduces the proportion of flux added during smelting and improves the smelting intensity. Second, the alkaline flux can be combined with aluminum in iron concentrate. , Silicon and other acidic substances react to form substances with low melting points, so as to obtain a liquid phase at a reduced temperature and improve the strength and metallurgical properties of sintered ore. Alkaline fluxes include limestone, quicklime, dolomite, slaked lime, etc. Quicklime is widely used becau...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01F11/02C22B1/02

CPCC01F11/02C22B1/02

Inventor 王学军郭会良张延新孟海燕张林才彭鹏

Owner SHANDONG TAISHAN STEEL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com