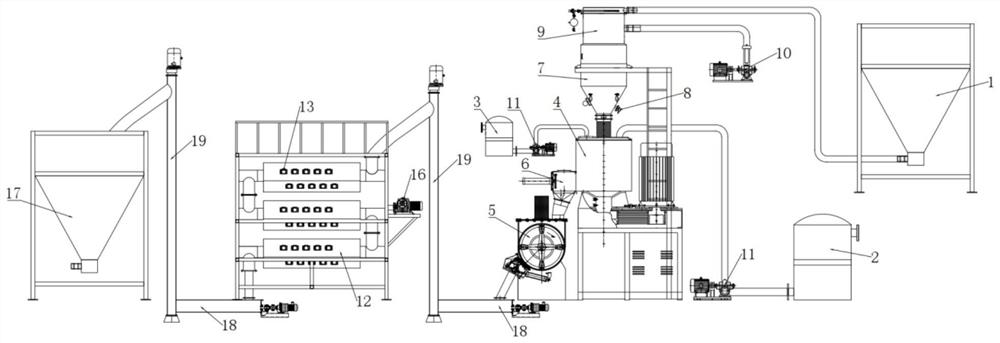

Microwave radiation rubber powder continuous production system and method

A microwave radiation and production system technology, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of long production time, large amount of exhaust gas, poor storage stability, etc., to prolong the service life of roads, increase high temperature resistance to rutting, The effect of good high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

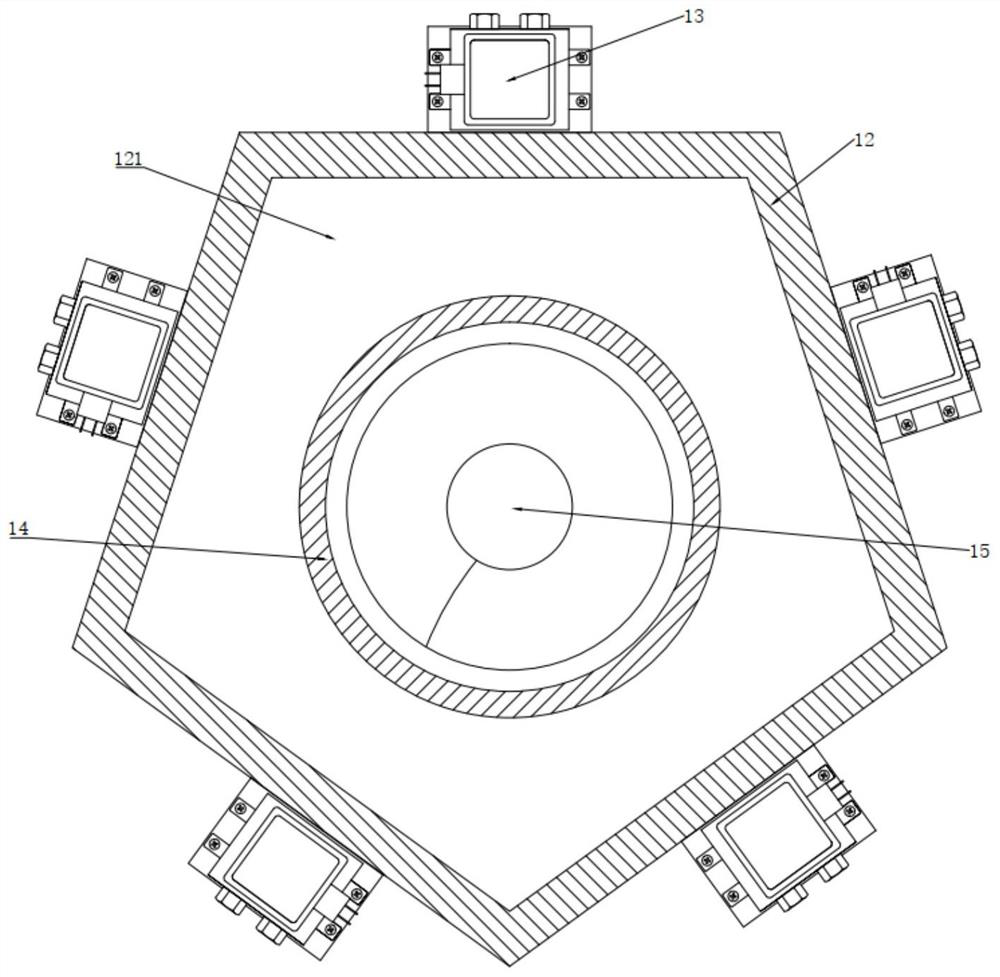

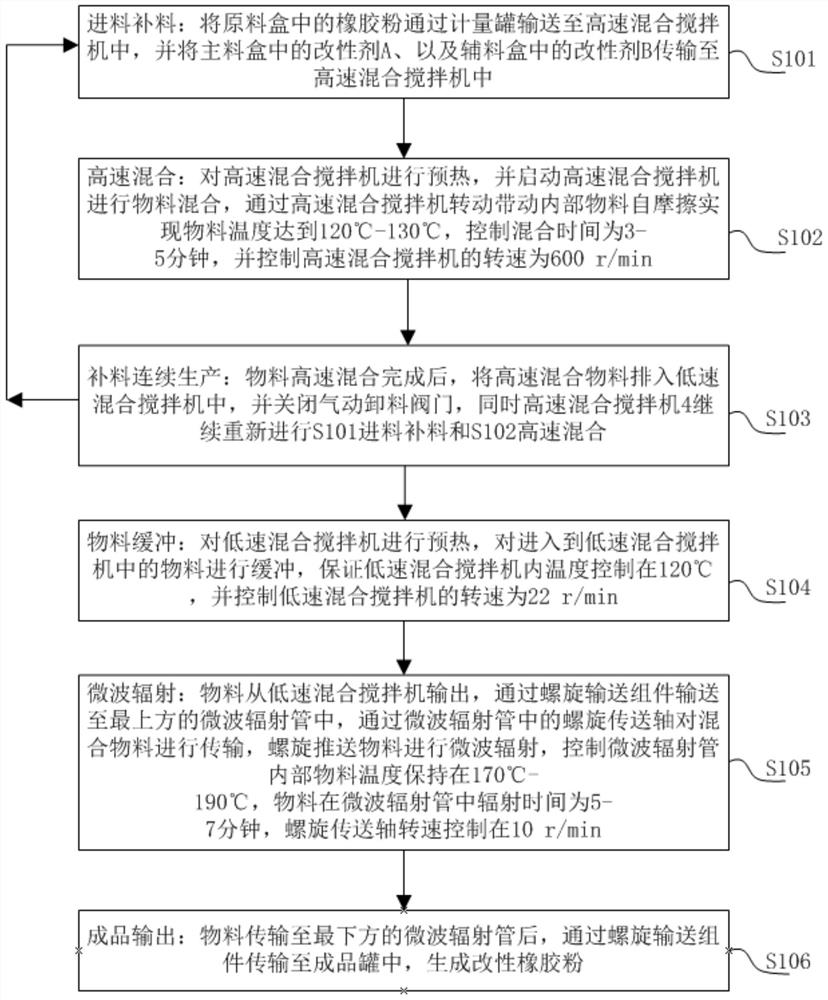

[0059] A method for continuous production of microwave irradiated rubber powder is used in a continuous production system of microwave irradiated rubber powder, comprising the steps of:

[0060] S201, feeding supplementary materials: 200KG rubber powder in the raw material box 1 is transported in the high-speed mixing mixer 4 through the metering tank 7, and 20KG modifier A in the main material box 2, the modifier A is aromatic hydrocarbon oil, And the 2.2KG modifier B in the auxiliary material box 3, the modifier B is thiophenol zinc salt, all transferred to the high-speed mixer 4;

[0061] S202, high-speed mixing: preheat the high-speed mixing mixer 4, start the high-speed mixing mixer 4 for material mixing, drive the internal material self-friction through the high-speed mixing mixer 4 to achieve a material temperature of 120°C, control the mixing time to 5 minutes, and Control the rotating speed of high-speed mixer 4 to be 600r / min;

[0062] S203. Continuous production of...

Embodiment 2

[0067] A method for continuous production of microwave irradiated rubber powder is used in a continuous production system of microwave irradiated rubber powder, comprising the steps of:

[0068] S301. Feed and replenishment: 200KG rubber powder in the raw material box 1 is transported to the high-speed mixing mixer 4 through the metering tank 7, and 18KG of the modifier A in the main material box 2 is used, and the modifier A is aromatic hydrocarbon oil. , and the 2.0KG gram modifier B in the auxiliary material box 3, the modifier B is a polyalkylphenol sulfide, which is transmitted to the high-speed mixing mixer 4;

[0069] S302, high-speed mixing: preheat the high-speed mixing mixer 4, start the high-speed mixing mixer 4 for material mixing, drive the internal material self-friction through the high-speed mixing mixer 4 to achieve a material temperature of 130°C, control the mixing time to 3 minutes, and Control the rotating speed of high-speed mixer 4 to be 600r / min;

[00...

Embodiment 3

[0075] A method for continuous production of microwave irradiated rubber powder is used in a continuous production system of microwave irradiated rubber powder, comprising the steps of:

[0076] S401. Feed and replenishment: 200KG rubber powder in the raw material box 1 is transported to the high-speed mixing mixer 4 through the metering tank 7, and 21KG of the modifier A in the main material box 2 is used, and the modifier A is aromatic hydrocarbon oil. , and the 1.9KG gram modifier B in the auxiliary material box 3, the modifier B is thiophenol, which is transmitted to the high-speed mixing mixer 4;

[0077] S402, high-speed mixing: preheat the high-speed mixing mixer 4, and start the high-speed mixing mixer 4 for material mixing, drive the internal material self-friction through the high-speed mixing mixer 4 to achieve a material temperature of 128°C, control the mixing time to 4 minutes, and Control the rotating speed of high-speed mixer 4 to be 600r / min;

[0078] S403. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com