Mercury removal adsorbent suitable for coal-fired flue gas and preparation method thereof

A technology of coal-fired flue gas and adsorbent, which is applied in the field of mercury removal adsorbent and its preparation, can solve the problems of unstable performance of mercury removal adsorbent, difficult application in production process, cumbersome preparation process, etc. The effect of stable adsorption product and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

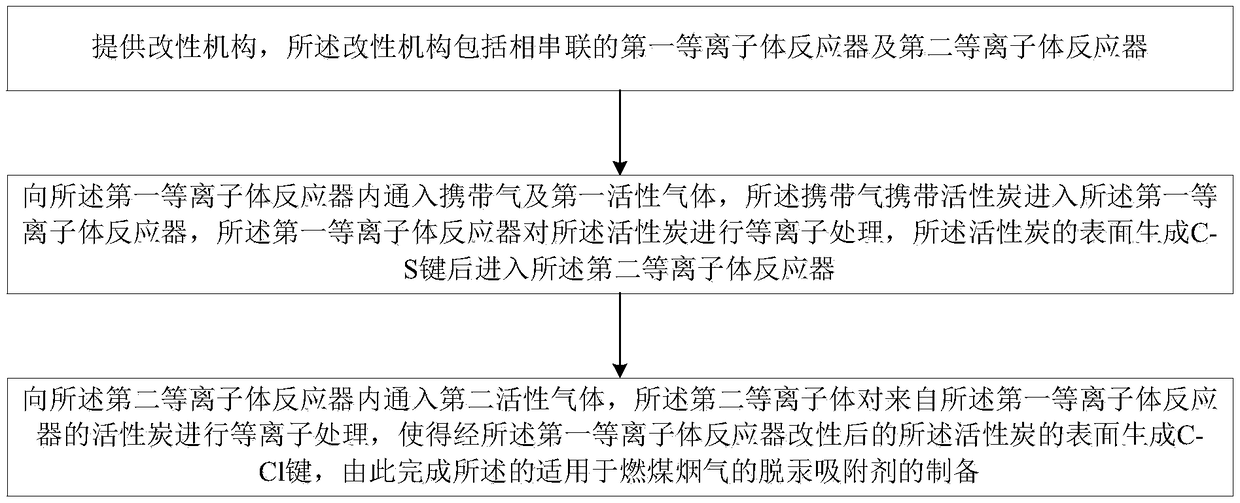

[0029] The preparation method mainly comprises the following steps:

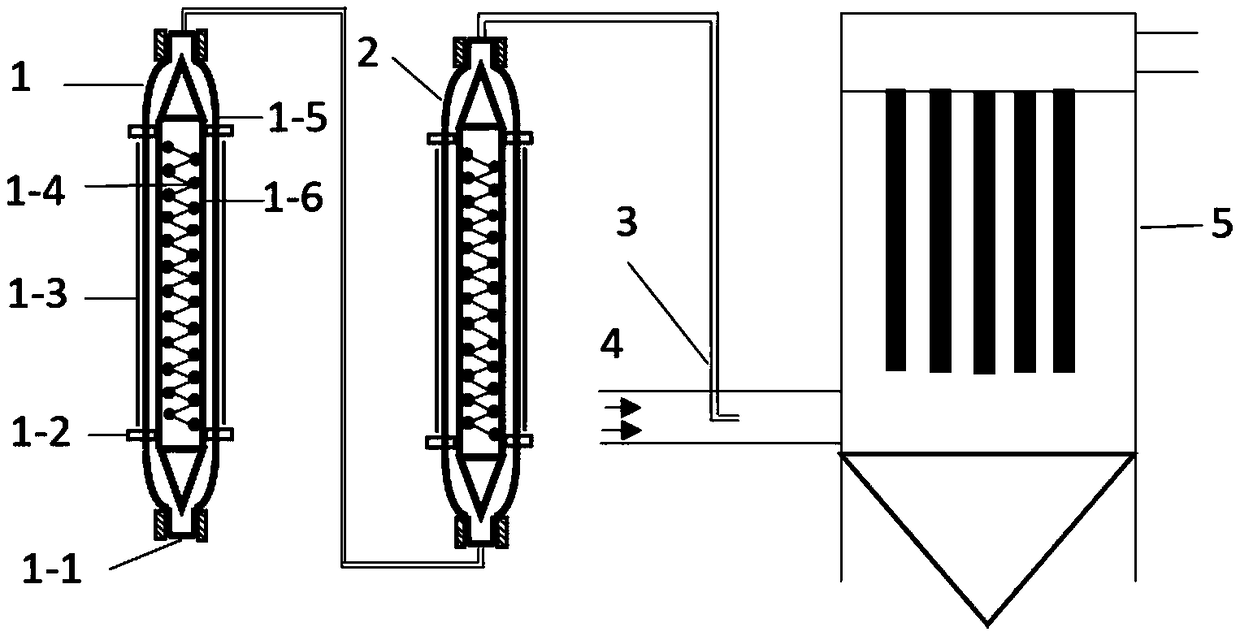

[0030]Step 1, providing a modification mechanism, which includes a first plasma reactor 1 and a second plasma reactor 2 connected in series. The second plasma reactor 2 is connected to a spray gun 3 . The spray gun 3 communicates with the coal-fired flue gas pipeline 4 , and the coal-fired flue gas pipeline 4 is connected to the bag filter 5 . In this embodiment, the injection gun 3 is made of a stainless steel round tube, which is used to inject the mercury-removing adsorbent from the second plasma reactor 2 into the coal-burning pipeline 4 . The bag filter 5 is used to collect the mercury-removing adsorbent after absorbing mercury. The first plasma reactor 1 and the second plasma reactor 2 are connected by stainless steel pipes, and the second plasma reactor 2 and the spray gun 3 are connected by hoses.

[0031] The structure of the first plasma reactor 1 is the same as that of the second plasma reactor...

Embodiment 1

[0044] Adjust the flow rate and flow rate of the carrier gas, the residence time of the activated carbon powder in the first plasma reactor 1 and the second plasma reactor 2 is 0.1 second, and the first plasma reactor 1 and the output voltage of the second plasma reactor 2 is set to 35kV.

[0045] Wherein, the purified SO is introduced into the first plasma reactor 1 2 Exhaust gas, because the carrier gas is compressed air, has a high oxygen concentration. In the first plasma reactor 1, the reaction 2SO 2 +O 2 →2SO 3 , 2SO 3 +2AC→2AC-S+2O 3 ; Pass into pure Cl in the second plasma reactor 2 2 , use the bag filter 5 to collect the modified activated carbon powder at the outlet of the second plasma reactor 2.

[0046] In order to verify the mercury removal performance of the activated carbon powder, a mercury adsorption test was carried out on the obtained activated carbon powder on a fixed bed, the process of adsorbing mercury is:

[0047] Hg+AC-Cl→AC-Hg-Cl;

[0048] 2...

Embodiment 2

[0051] Regulate the flow rate and the flow rate of carrying gas, the residence time of activated carbon powder in the first plasma reactor 1 and the second plasma reactor 2 is 0.1 second, and the first plasma reactor 1 and the second plasma reactor 2 The output voltage of the second plasma reactor 2 is set to 35kV.

[0052] Wherein, pure H is introduced into the first plasma reactor 1 2 S gas, Cl is introduced into the second plasma reactor 2 2 , use the bag filter 5 to collect the modified activated carbon powder at the outlet of the second plasma reactor 2. In addition, in order to verify the mercury removal performance of the activated carbon powder, a mercury adsorption test was carried out on the obtained activated carbon powder on a fixed bed. The test results showed that the adsorption efficiency continued at 96% in the first 60 minutes of the adsorption test. The adsorption efficiency gradually decreased to 92% between the 60th minute and the 120th minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com