Preparation method of composite modified asphalt

A technology of compound modified asphalt and compound modifier, applied in building components, building insulation materials, buildings, etc., can solve problems such as easy segregation, avoid conventional shearing process, improve compatibility, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

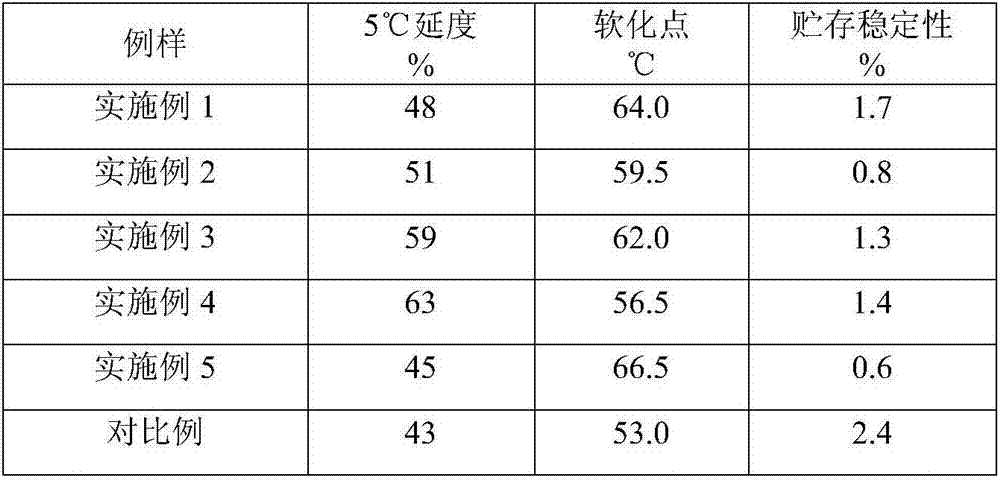

[0015] The raw material composition ratio of the composite modified asphalt in Examples 1-5 of the present invention is shown in Table 1:

[0016] Table 1 The raw material composition ratio of asphalt composite modifier

[0017] Example

Polyphosphoric acid (Kg)

SBS(Kg)

Asphalt (Kg)

1

2

2

100

2

2

3

100

3

2

4

100

4

1

3

100

5

3

3

100

[0018] The preparation method of the composite modified asphalt in Examples 1-5 of the present invention is:

[0019] a. Prepare various raw materials according to the above raw material composition ratio;

[0020] b. Heat the inorganic modifier polyphosphoric acid to 105°C and keep it warm;

[0021] c. Heat the organic modifier styrene-butadiene block copolymer SBS to 65°C, then add it to the insulated polyphosphoric acid, heat up to 120°C, and stir at 120r / min until there is no obvious Styrene-butadiene block copolymer particles exist to prepare asphalt composite modifier;

[0022] d. Heat the asphalt to 135°C, then add the asphalt composite modifier prepared abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com