Method for preparing efficient heavy metal adsorbent from modified cotton stalk biomass charcoal

A biomass charcoal, cotton straw technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of small pore size, low performance, long reaction time, etc. The effect of short sex time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

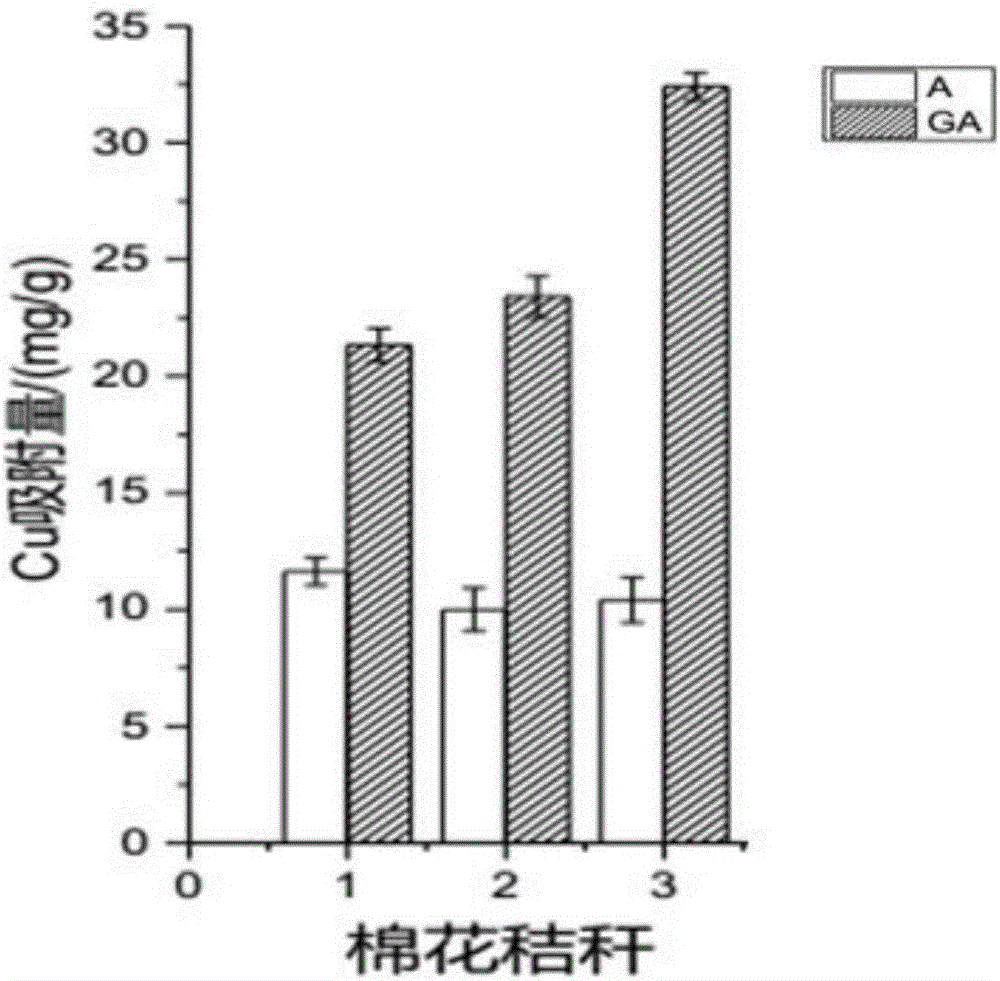

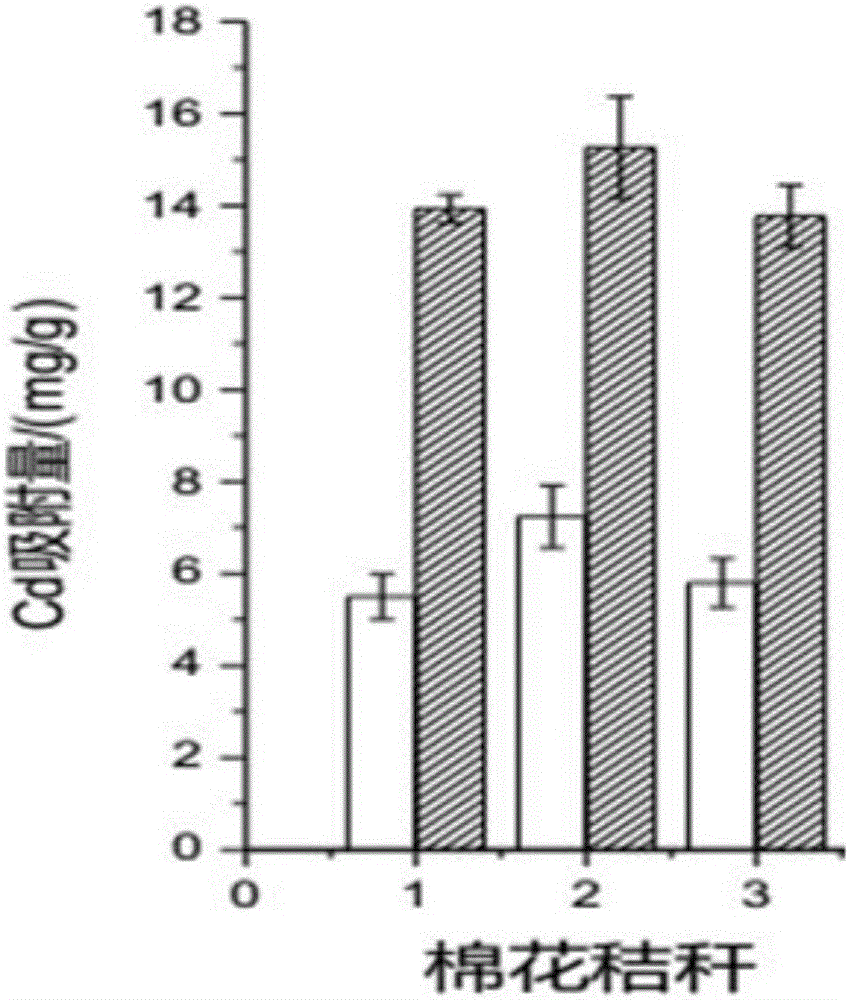

Embodiment 1

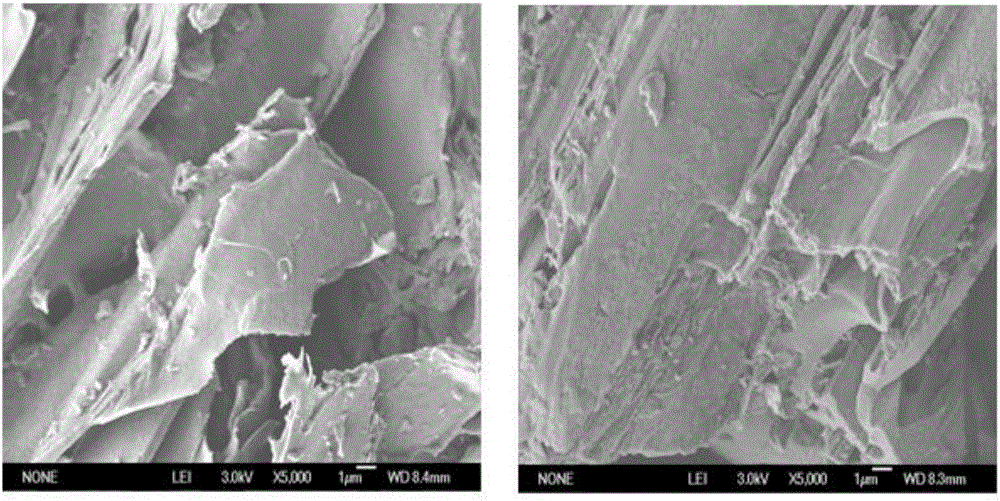

[0023] The preparation method of cotton biochar: cut the washed and dried cotton stalks into pieces, put them into a pulverizer for preliminary crushing, sieve the crushed stalks, weigh the 100-mesh cotton and put it in a ceramic crucible. Carbonize in a Furnace at 300°C for 6h. The carbonized biochar was weighed, and the carbonization rate of the straw was calculated to be 48.04%.

[0024] Modification method of biochar: first add 0.3mol / L KMnO to 1g of biochar 4 Solution 7.4ml, then add 3.6ml60%HNO 3 The solution was heated in a temperature-controlled water bath at 90°C for 3 hours, filtered through filter paper, and the biochar was washed with deionized water until the pH of the filtrate was constant. Put the filter residue and filter paper in an evaporating dish and bake at 80°C for 7 hours.

Embodiment 2

[0026] Cut the cleaned and dried cotton stalks into pieces, put them into a pulverizer for preliminary crushing, sieve the crushed stalks, weigh the sieved 60-mesh cotton, put it in a ceramic crucible, and put it in a muffle furnace at a temperature of 300 ° C. Carbonization 4.5h. The carbonized biochar was weighed, and the carbonization rate of the straw was calculated to be 46.43%.

[0027] Modification method of biochar: first add 0.3mol / L KMnO to 1g of biochar 4 Solution 7ml, then add 3.3ml60%HNO 3 The solution was heated in a temperature-controlled water bath at 90°C for 3 hours, filtered with filter paper, and the biochar was washed with deionized water until the pH of the filtrate was constant. Put the filter residue and filter paper in an evaporating dish and bake at 80°C for 8 hours.

Embodiment 3

[0029] Cut the cleaned and dried cotton stalks into pieces, put them into a pulverizer for preliminary crushing, sieve the crushed stalks, weigh the sieved 20-mesh cotton, put it in a ceramic crucible, and put it in a muffle furnace at a temperature of 300 ° C. Carbonization for 3h. The carbonized biochar was weighed, and the carbonization rate of the straw was calculated to be 44.89%.

[0030] Modification method of biochar: first add 0.3mol / L KMnO to 1g of biochar 4 Solution 7.8ml, then add 4.0ml60%HNO 3 The solution was heated in a temperature-controlled water bath at 90°C for 3 hours, filtered with filter paper, and the biochar was washed with deionized water until the pH of the filtrate was constant. Put the filter residue and filter paper in an evaporating dish and bake at 80°C for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com