System for recycling condensate of extraction torch tank

A torch and condensate technology, applied in the fields of hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve problems such as unqualified mixed aromatic products, improve non-aromatic content, facilitate product quality control, and solve circulating solvent problems. Effects of deterioration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

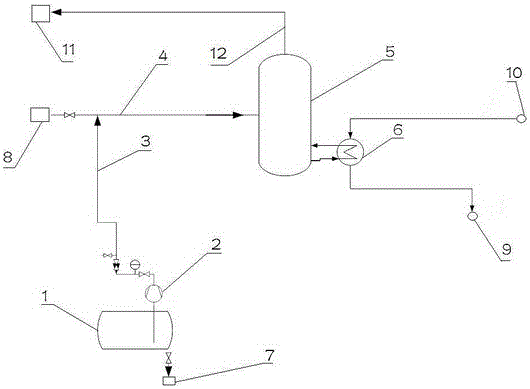

[0018] An extraction torch tank condensate recycling system, which includes an extraction torch tank 1, a wet solvent tank 7, a torch tank condensate pump 2, a torch tank condensate pipeline 3, an extraction solvent circulation pipeline 4, and a lean solvent pump 8 , extraction distillation tower 5, extraction distillation tower reboiler 6, non-aromatic hydrocarbon gas phase pipeline 12 and non-aromatic hydrocarbon distillation tower 11; wet solvent tank 7 is connected to extraction flare tank 1, and extraction flare tank 1 is connected to flare tank by pipeline The condensate pump 2; the torch tank condensate pump 2 is connected to the extraction solvent circulation pipeline 4 through the torch tank condensate pipeline 3; one end of the extraction solvent circulation pipeline 4 is connected to the lean solvent pump 8, and the other end is connected to the extraction distillation tower 5; The top of the extractive distillation tower 5 is connected to the non-aromatic hydrocarbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com