Method for eliminating screen printing edge bold lines and screen printing plate capable of eliminating edge bold lines

A technology of screen printing and edge, which is applied in the direction of screen printing machine, printing, printing machine, etc., can solve the problem of deformation of the edge of screen 11, and achieve the effect of improving the yield rate and being easy to realize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

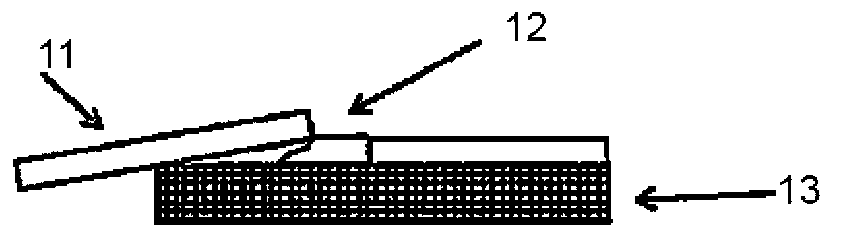

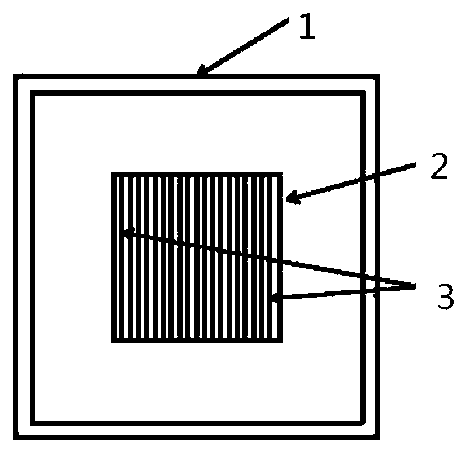

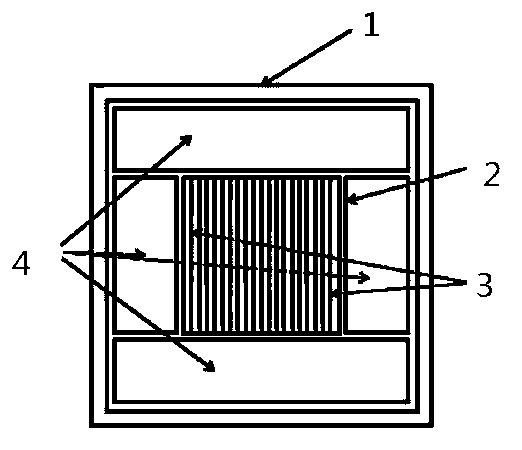

[0015] Such as image 3 with Figure 4 As shown, the method of the present invention for eliminating the thick line on the edge of the screen printing completely solves the problem of thick printing on both sides of the edge of the screen printing process through creative modification without affecting the overall manufacturing process of the stencil screen. Specifically, in one embodiment, the present invention has the following process steps: patterning, mask making by exposure, nickel electroplating, stretching the screen and raising the screen plate with a layer layer. The method of the present invention adopts the method of setting the layer 4 on the periphery of the graphic area 2 on the screen frame 1, so that when printing the battery sheet, the screen plate is always kept on the same level of the battery sheet 6 or close to the same level, thereby avoiding The outermost grid line 3 is thicker due to the edge deformation or excessive deformation of the screen. In spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com