Chip removal type anti-overflowing nozzle

An anti-overflow and nozzle cap technology is applied in the field of injection molding machine parts to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

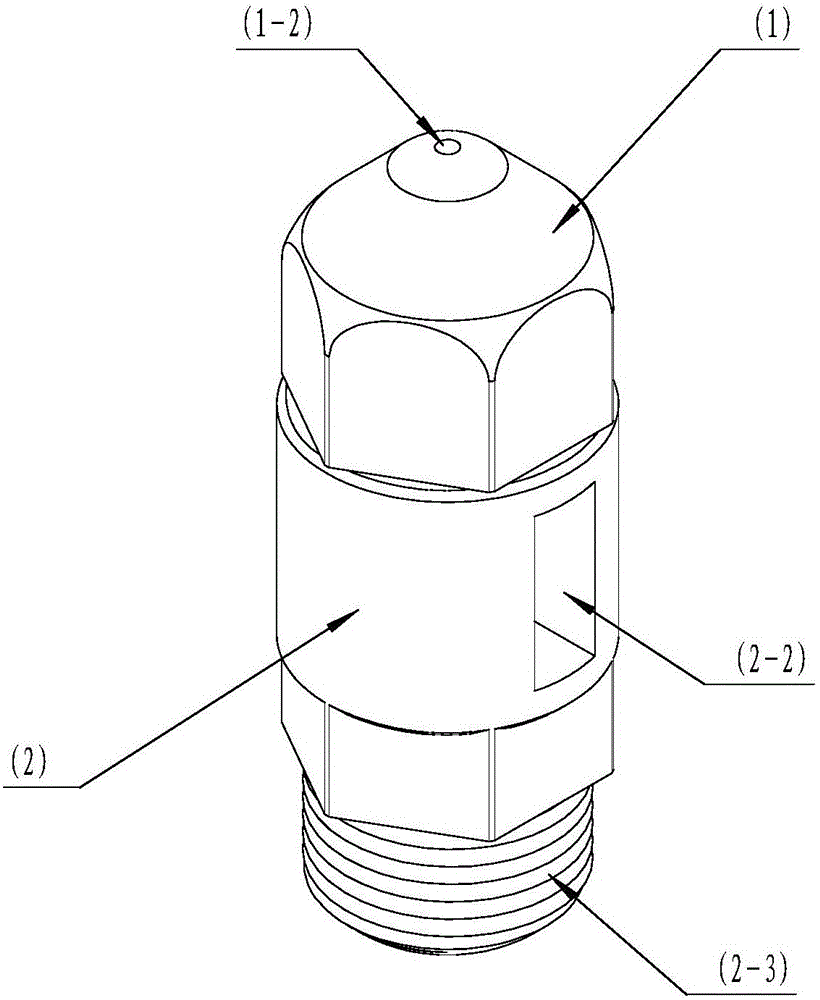

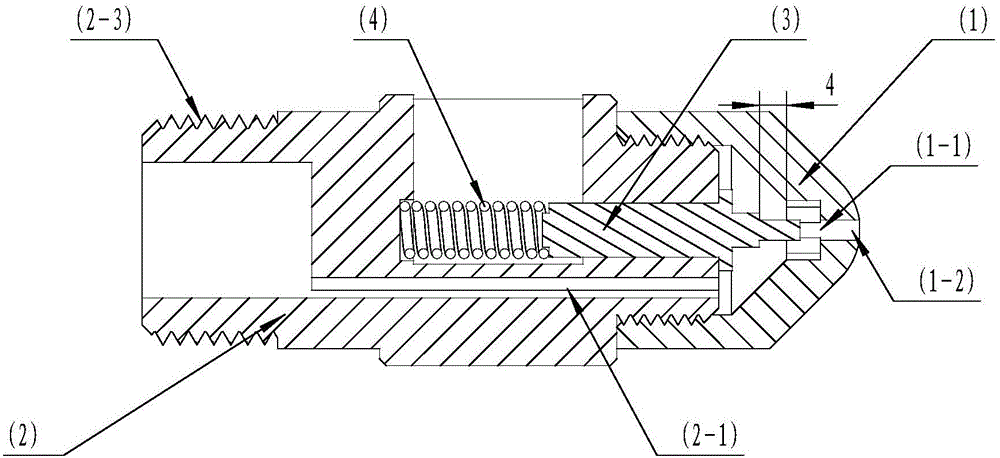

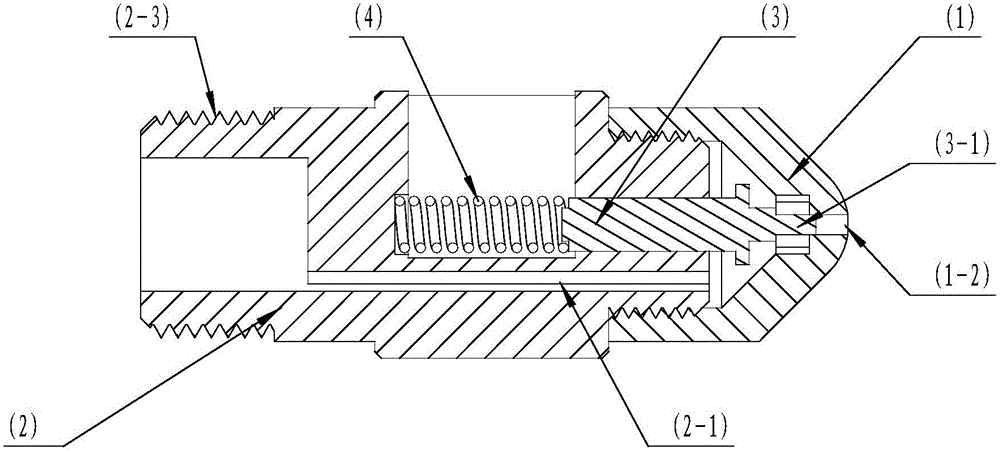

[0014] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The chip removal type anti-overflow nozzle includes a nozzle cap (1), a nozzle body (2), a valve core (3) and a spring (4) as the main components. Its characteristics: during injection molding, the hydraulic device pushes the screw forward, forming a high-pressure glue melting area in the originally closed nozzle cap (1), and the high-pressure melting glue acts on the force surface (3-2) of the valve core (3). Then, a thrust is generated to compress the spring (4) to move the valve core (3) in the direction of the spring (4) until the limiting surface (3-4) of the valve core (3) is in contact with the nozzle body (2). The blocking column (3-1) of the valve core (3) is completely withdrawn from the injection channel (1-1) of the nozzle cap (1), such as figure 2 At this time, the molten glue is injected into the cavity of the mold through the injection channel (2-1), injection channel (1-3) and injection channel (1-1) of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com